I inch cryogenic flow meter means: a flow meter with DN25 (one inch) size for accurately measuring media at minus 273 °C ultra-low temperature applications.

In the field of industrial measurement, when the temperature drops sharply to minus 273 degrees Celsius in extremely cold environments, ordinary

flow meters are often helpless, For example,

liquid turbine flowmeter can only measure liquids at a minimum temperature of -20 degrees Celsius. At this point, the 1-inch Coriolis ultra-low temperature flowmeter became the preferred tool for engineers. This device, which adopts advanced measurement principles, can maintain stable operation under extreme conditions where most instruments would freeze.

Why choose the Coriolis principle to measure ultra-low temperature media?

The Coriolis flow meter works by measuring the Coriolis force generated by the fluid in a vibrating tube, which is independent of the fluid temperature, making it an ideal choice for ultra-low temperature measurement.

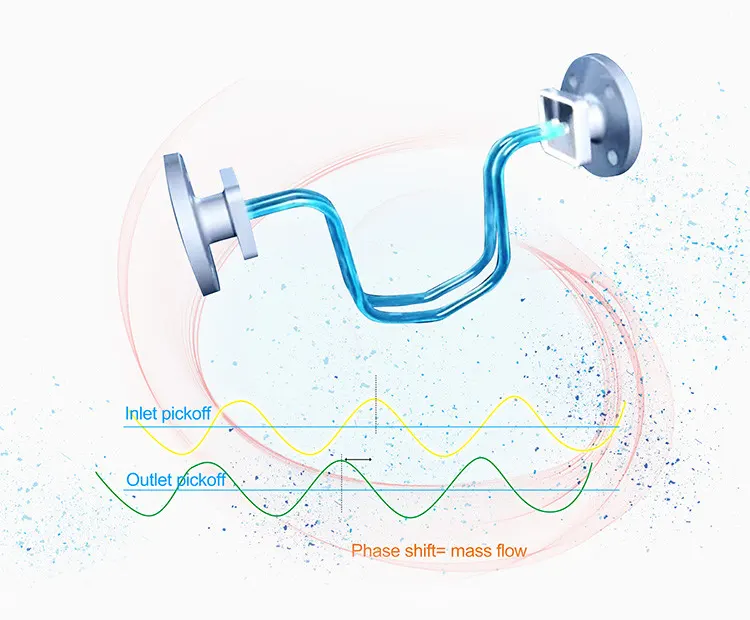

How 1 inch cryogenic flow meter works

When liquid nitrogen, liquid methane and other media flow through a vibrating measuring tube, the degree of distortion of the tube is proportional to the mass flow rate, while the vibration frequency reflects the fluid density. This dual measurement capability enables the Coriolis flowmeter to not only measure flow rate, but also simultaneously monitor medium density and temperature.

Which ultra-low temperature media require this special flowmeter?

A 1-inch Coriolis ultra-low temperature flowmeter is commonly used to measure the following media:

-Liquefied Natural Gas (LNG): The main component is liquid methane (LCH4), which is approximately -162 °C and used for energy storage and transportation

-Liquid methane (LCH4): -161.5 °C, used as a clean fuel and chemical raw material

-Liquid nitrogen (LN2): -196 °C, used in food freezing, medical, and industrial applications

-Liquid Oxygen (LOX): -183 °C, used in medical and aerospace fields

-Liquid argon: -186 °C, welding protection and laboratory use

-Liquid carbon dioxide: -78.5 °C, food processing and fire extinguishing systems

-Liquid Hydrogen: -253 °C, Aerospace Fuel and New Energy Research

These cryogenic media are widely used in fields such as air separation equipment, LNG refueling stations, methane storage and transportation systems, low-temperature laboratories, semiconductor manufacturing, aerospace fuel systems, and specialty chemicals. For example, in LNG refueling stations, a 1-inch ultra-low temperature flow meter can meet the flow measurement needs of liquid methane without causing excessive pipeline pressure loss.

Key technical parameters of ultra-low temperature flowmeter

A typical 1-inch Coriolis ultra-low temperature flowmeter typically has the following performance indicators:

-

Flow range for DN25 (1 inch) Coriolis flow meter: 13 t/h, 7.96 lb/s, 217 kg/min,

-

Temperature range: -273°C to+450 °C (special design can reach lower temperatures)

-

Pressure rating: ranging from ANSI 150 # to 1500 #, depending on application requirements, can be made into

high pressure flow meter, such as 1000 psi, 10000 psi pressure rating.

-

Accuracy level: Mass flow rate ± 0.1%~0.5%, density measurement ± 0.0005 g/cm ³

-

Material selection: 316L stainless steel is the main material, and special sealing treatment is required for liquid methane applications. There are also materials to choose from for the wet parts material of ultra-low temperature sensors 1 inch, such as Hastelloy, high nickel alloy, titanium alloy, tantalum material, etc.

-

Protection level: usually IP67, explosion-proof version optional (especially important for methane measurement),

silverinstruments.com has ATEX certified DN25 cryogenic fluids.

-

Output signal: 4-20mA, pulse, MODBUS, HART, Profibuds-DP etc

-

Power Requirements: 24VDC or 220VAC

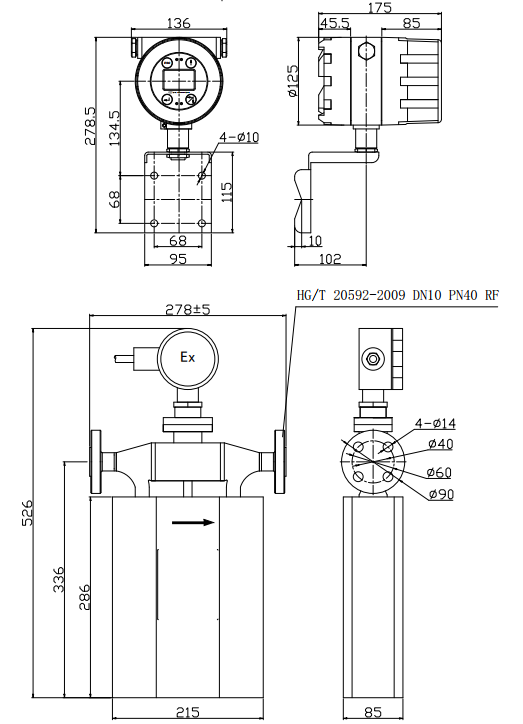

- Drawing for 1-inch ultra-low temperature flow meter

1 inch cryogenic flow meter dimensions

It is worth noting that models used for liquid methane measurement pay special attention to explosion-proof safety (ATEX certified mass flow meter) and sealing performance. The measuring tube will adopt a thin-walled design to improve sensitivity, and the entire sensor part will have a vacuum insulation layer to prevent external heat from entering.

With the development of clean energy and cutting-edge technology, the demand for ultra-low temperature flow measurement continues to grow. The 1-inch Coriolis ultra-low temperature flowmeter is becoming a standard configuration in these demanding applications due to its excellent accuracy and reliability. Whether it is ensuring the precise refueling of liquid methane fuel or ensuring the measurement of liquid oxygen propellants for rockets, these "not afraid of cold" measurement experts are silently playing a key role.