Methyl Chloride Flow Meter

Related Products

Liquid mass flow meter-Coriolis flow meter

The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...

Inline turbine flow meter is a precisionflow measuring instrument that can be used to measure the flow and total volumeof the media. Inline turbine flow meter has compact and light weight structure,ea...

| Size (mm) | Standard Flow (m3/h) | Extended Flow (m3/h) |

|---|---|---|

| DN4 (1/8 inch) | 0.04-0.25 | 0.04-0.24 |

| DN6 (1/4 inch) | 0.1-0.6 | 0.06-0.6 |

| DN10 (3/8 inch) | 0.2-1.2 | 0.15-1.5 |

| DN15(1/2inch) | 0.6-6 | 0.4-8 |

| DN20 (3/4 inch) | 0.8-8 | 0.45-9 |

| DN25 (1 inch) | 45667 | 0.5-10 |

| DN32 (1-1/4inch) | 1.5-15 | 0.8-15 |

| DN40(1-1/2 inch) | 45708 | 45677 |

| DN50 (2 inch) | 4-40 | 2-40 |

| DN65 (2-1/2 inch) | 7-70 | 4-70 |

| DN80 (3 inch) | 10-100 | 5-100 |

| DN100 (4 inch) | 20-200 | 10-200 |

| DN125 (5 inch) | 25-250 | 13-250 |

| DN150 (6 inch) | 30-300 | 15-300 |

| DN200 (8 inch) | 80-800 | 40-800 |

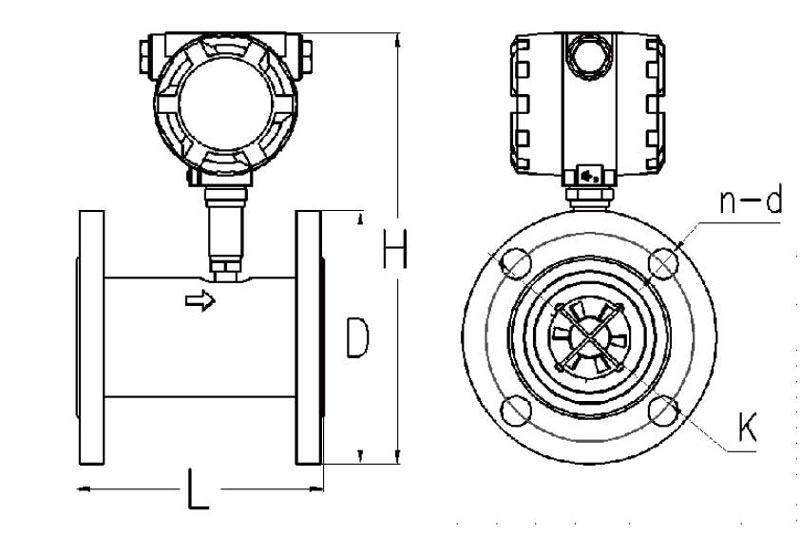

| Diameter (mm) | L (mm) | D (mm) | K (mm) | H(mm) | d (mm) | n | Press. Rate | |||

| Pulse | Pulse with Ex | 4-20mA with Ex | Digital Display | |||||||

| 15 | 75 | 95 | 65 | 175 | 180 | 180 | 245 | 14 | 4 | 2.5 Mpa |

| 20 | 80 | 105 | 75 | 185 | 190 | 190 | 255 | 14 | 4 | |

| 25 | 100 | 115 | 85 | 200 | 195 | 195 | 260 | 14 | 4 | |

| 32 | 140 | 140 | 100 | 210 | 215 | 215 | 275 | 18 | 4 | |

| 40 | 140 | 150 | 110 | 195 | 220 | 220 | 285 | 18 | 4 | |

| 50 | 150 | 165 | 125 | 230 | 235 | 235 | 295 | 18 | 4 | |

| 65 | 170 | 185 | 145 | 255 | 260 | 260 | 325 | 18 | 4 | 1.6 Mpa |

| 80 | 200 | 200 | 160 | 260 | 265 | 265 | 330 | 18 | 8 | |

| 100 | 220 | 220 | 180 | 285 | 285 | 285 | 350 | 18 | 8 | |

| 125 | 250 | 250 | 210 | 310 | 315 | 315 | 380 | 18 | 8 | |

| 150 | 300 | 285 | 240 | 345 | 345 | 345 | 410 | 22 | 8 | |

| 200 | 360 | 340 | 295 | 395 | 400 | 400 | 465 | 22 | 12 | |

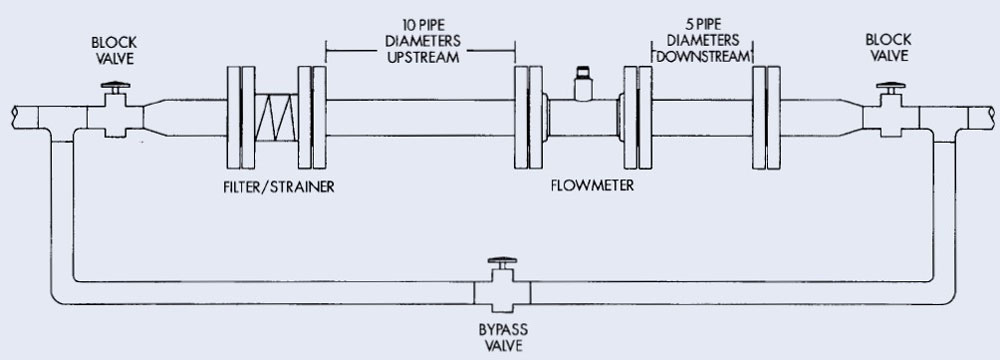

The recommended guidelines are given to enhance accuracy and maximize performance. Distance given here are minimum requirements; double them for desired straight pipe lengths.

Upstream: allow a minimum straight pipe length of at least 10 times the pipe's internal diameter. For example, with the 50mm pipe, 500mm of straight pipe should be immediately upstream. The desired upstream straight pipe length is 1000mm.

Downstream: allow a minimum straight pipe length of at least 5 times the pipe's internal diameter. For example, with the 50mm pipe, there should be 250mm of straight pipe immediately upstream. The desired upstream straight pipe length is 500mm.

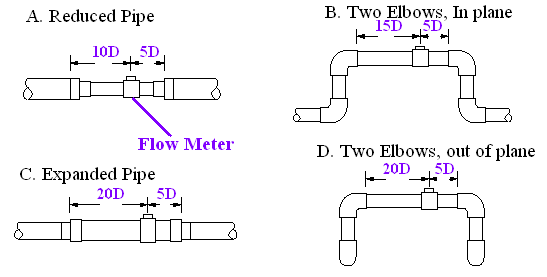

See diagram 2 for the straight pipe length requirement when there is an altering device.

Conclusion

For safe and efficient methyl chloride flow measurement, liquid turbine flow meters offer a reliable, cost-effective solution. Their high accuracy, durability, and ease of use make them a economical choice for industries handling this critical chemical.

Need a methyl chloride flow meter? Contact us (SALES@SILVERINSTRUMENTS.COM) today for expert advice!

we will contact you within 24 hours.