Transformer oil, a critical insulating and cooling medium in electrical equipment, requires precise flow monitoring to ensure operational safety and energy efficiency. Oval gear flow meters, it is a kind of positive displacement flow meter (PD flow meter), known for their high accuracy and durability, excel in measuring different kinds of oil , such as diesel, crude oil, kerosene , vegetable oil ,transformer oil volumetric flow. This article explores oval gear flow sensor working principles, technical features, selection criteria, and industry applications.

How Oval Gear Flow Meters Work

Oval gear flow meters use two rotating oval gears to measure fluid volume. Transformer oil flows through the meter, driven by pressure differences, creating "crescent-shaped chambers" that fill and empty cyclically. Gear rotations calculate cumulative flow and generate real-time flow signals.

This mechanical design requires no electronics, making it ideal for explosive or high-EMI environments. Due to its superior anti-interference performance,

mechanical flow meters are often favored by customers. It is also viscosity-independent, ensuring stable performance for transformer oil (typically 10–50 mPa·s). Liquid turbines flow meter are often used to measure oil, but liquid turbine flow meters can only measure low viscosity oils such as diesel, fish oil, peanut oil, edible oil, etc. Sometimes the viscosity of transfer oil is relatively high, and the measurement effect of liquid turbine is not good.

Key Advantages for Transformer Oil Measurement

-

High Accuracy & Repeatability

Accuracy up to ±0.5% (some models ±0.2%), meeting strict industrial and trade standards. Positive displacement flowmeter is a traditional high accuracy flowmeter that is widely used by many people.

oTemperature: -30°C to +200°C, suitable for cold starts and high-temperature oil flow measurement applications.

oPressure: Supports 1.6–6.3 MPa, ideal for high-pressure transformer oil pipelines.

Stainless steel or cast iron construction resists acidic impurities in transformer oil.

-

Low Maintenance & Longevity

oval gear flow meter has simple mechanical design and robust construction. Proper filtration prevents debris damage, ensuring oval gear flow sensor with long-term reliability with low upkeep.

Selection & Installation Guidelines for Transformer Oil flow meter

1. Critical Parameters

-

Viscosity Range: Ensure compatibility with transformer oil (e.g., 0.6–200 mPa·s). The elliptical gear flowmeter can measure a oil flow rate of up to 2000cp, but if it exceeds 200cp, it belongs to a high viscosity flowmeter (https://www.silverinstruments.com/high-viscosity-oval-gear-flowmeter.html)and needs to be consulted and purchased from silverinstrruents.com.

-

Output Options: Mechanical type flow meter or Silver Automation Instruments can make digital oval gear flow meter with Pulse, 4–20mA, or RS485 for system integration.

-

Material: Carbon steel, cast iron or stainless steel (e.g., 304SS ) for non corrosive oil or corrosive liquid.

-

Transformer oil Flow Meter size : We offer transformer oil flow meters in sizes ranging from 2mm to 8 inches (DN2 to DN200).

Below is reference table for oval gear flow meter flow range for transformer oil

|

Model

|

DN

|

Flow range for different accuracy (m3/h)

|

|

LC-10

|

10 (3/8”)

|

0.08-0.5

|

0.05-0.5

|

|

LC-15

|

15 (1/2”)

|

0.3-1.5

|

0.15-1.5

|

|

LC-20

|

20 (3/4”)

|

0.5-3

|

0.3-3

|

|

LC-25

|

25 (1”)

|

1-6

|

0.6-6

|

|

LC-40

|

40 (1.5”)

|

2.5-15

|

1.5-15

|

|

LC-50

|

50 (2”)

|

4.8-24

|

2.4-24

|

|

LC-B40,50

|

40.50

|

4-20

|

2-20

|

|

LC-B65

|

65(1.5 ”)

|

8-40

|

4-40

|

|

LC-80

|

80 (3”)

|

12-60

|

6-60

|

|

LC-100

|

100 (4”)

|

20-100

|

10-100

|

|

LC-150

|

150 (6”)

|

38-190

|

19-190

|

|

LC-200

|

200 (8”)

|

56-340

|

34-340

|

|

Accuracy

Class

|

|

0.2 %

|

0.5

|

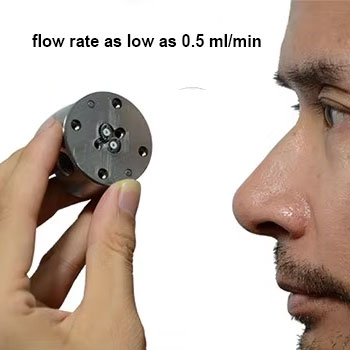

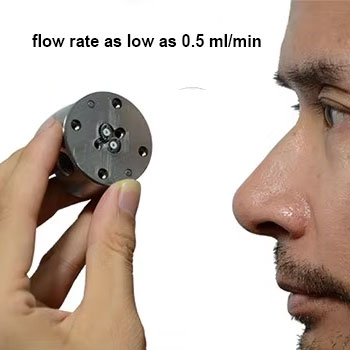

If you have lower flow range than above table listed, feel free to contact silverinstruments.com , we have

small flow meter for oil measurement. The min flow we can detect reaches to 0.5 ml/min.

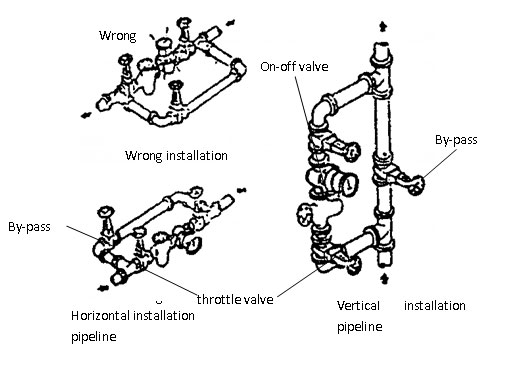

2. Installation Tips

- Mount horizontally with the display vertical to minimize errors.

- Install filters upstream to block debris.

- Add air eliminators to prevent bubble interference.

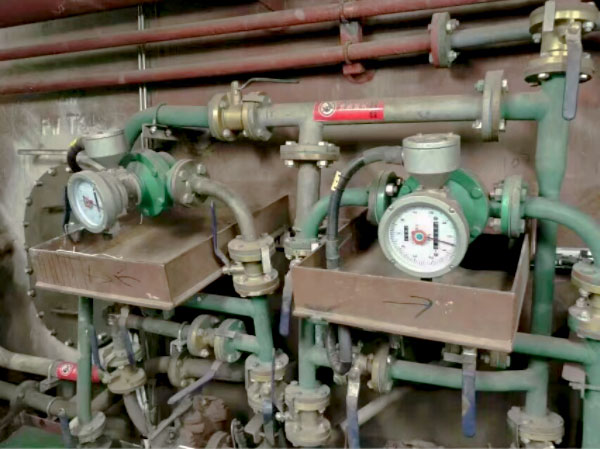

Below is typical install for transformer oil flow meter

4. Industry Applications

- Oil Filling & Circulation Monitoring: Ensures efficient cooling system performance.

- Trade Custody Transfer: High-precision measurement aligns with API/OIML standards.

- Predictive Maintenance: Detects leaks or blockages via flow anomalies.

5. Comparison with Other Technologies

-No Straight-Pipe Requirements: Flexible installation in tight spaces.

-Cost Efficiency: Lower maintenance vs. complex electronic meters.

-Mechanical or digital options. No matter you need mechanical transformer oil flow meter or digital oil flow meters,silverinstruments.com all have solutions.

-High accuracy flowmeter . You can get 0.2~0.5% high accuracy flow measurement.

Oval gear flow meter for transformer oil flow measurement with pulse output

Oval gear flow meters are ideal for transformer oil flow measurement due to their accuracy, adaptability, and robustness. Proper selection (matching oil properties and operating conditions) and installation ensure reliable performance. For power systems, they enhance operational efficiency while reducing energy loss and costs. Contact

silverinstruments.com to get your low price and suitable oil flow meters.