Why Flow Measurement Matters for Corrosion Inhibitors

Corrosion inhibitors are important chemicals used in oil & gas, water treatment, and industrial processes to protect pipelines and equipment from degradation. Accurate flow measurement ensures:

- Precise dosing of corrosion inhibitor – Under-dosing leads to insufficient protection, while over-dosing wastes expensive chemicals.

- Process efficiency – Real-time flow rate monitoring helps optimize inhibitor injection rates.

- Cost control – Accurate flow rate measurement prevents chemical overuse, reducing operational expenses.

Accurate corrosion inhibitor flow measurement matters

However, measuring corrosion inhibitor flow presents unique challenges:

Key Measurement Challenges:

- Extremely low flow rates (as low as 150 mL/min),

low flow rate flow meters are needed in these applications.

- High system pressure (up to 200 bar or more), for around 2900 psi or high pressure flow measurement, it is really tough for some plastic flow meters.

- Fluid viscosity variations due to temperature changes

- Chemical compatibility – Many flow meters degrade when exposed to aggressive inhibitors, so

stainless steel flow meters are demanding in these applications.

Conventional flow meters (

turbine flow meter,

electromagnetic flow meter, or

ultrasonic flow meters) often fail in these conditions due to insufficient sensitivity at low flows or high pressure limitations.

Conventional flow meters like magmeters fail in the low flow corrosion inhibitor flow measurement

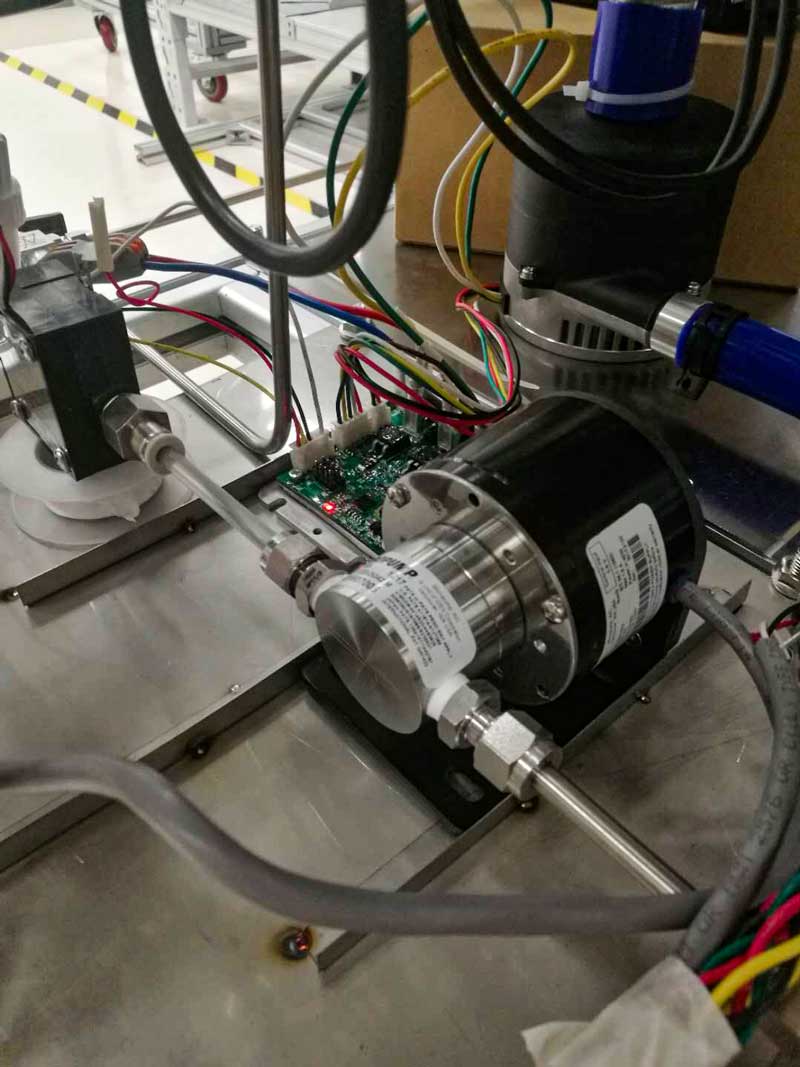

Micro Positive Displacement Flow Meters: The Optimal Solution for corrosion inhibitor flow

Micro positive displacement (PD) flow meters, particularly

oval gear flow meters , excel in corrosion inhibitor flow gauging applications due to their precision and durability.

Optimal corrosion inhibitor flow measurement solution by oval gear flow meter

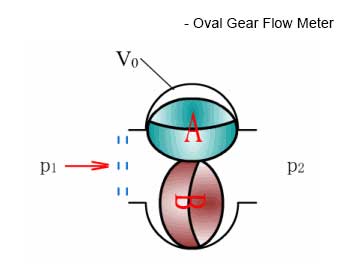

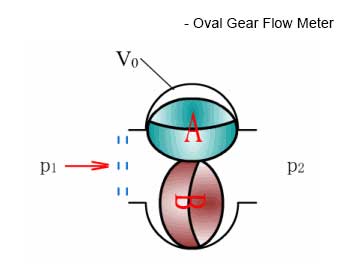

How oval Gear Flow Meters Work

1. Corrosion inhibitor enters the metering chamber, driving the rotation of two elliptical gears.

1. Corrosion inhibitor enters the metering chamber, driving the rotation of two elliptical gears.

2. Precise volumetric pockets trap a fixed corrosion inhibitor volume per rotation.

3. Gear movement is detected magnetically or via sensors, converting displacement into flow rate.

Advantages for Corrosion Inhibitor Measurement by oval gear flow meter:

✔ High accuracy even at low flows – Measures flow down to 1 mL/min with ±0.5% repeatability

✔ Handles extreme pressure – Robust construction withstands 200+ bar

✔ Viscosity-independent – Performance remains stable even with thickening inhibitors

✔ Chemical resistance – Available in 316 stainless steel for corrosive liquid measurement

✔ No straight-run piping required before and after corrosion inhibitor flow sensor– compact design simplifies installation

Technical Specifications of Micro PD Flow Meters for Inhibitor Applications

Flow range table:

|

Flow meter model

|

Flow Range

|

|

LC-M2-AL

|

0.5-150 ml/min

|

|

LC-M2-SS

|

0.5-150 ml/min

|

|

LC-M5.2-AL

|

1-400 ml/min

|

|

LC-M5.2-SS

|

1-400 ml/min

|

|

LC-M5.1-AL

|

1~800ml/min

|

|

LC-M5.1-SS

|

1~800ml/min

|

|

LC-M6-AL

|

0.5~100 L/H

|

|

LC-M6-SS

|

0.5~100 L/H

|

|

LC-M9-AL

|

6~600 L/H

|

|

LC-M9-SS

|

6~600 L/H

|

|

LC-M12-AL

|

0.3~30 L/min

|

|

LC-M12-SS

|

0.3~30 L/min

|

|

LC-M25-AL

|

0.5~100L/min

|

|

LC-M25-SS

|

0.5~100L/min

|

Pressure rating: standard pressure for flow meter is 16 bar, we can max make 100 Mpa( 14500 psi) high pressure flow meter.

Accuracy: +/-0.5FS

Flow sensor Material Options: stainless steel 316 or aluminum

Output signal: 4-20mA, pulse (NPN or PNP) , MODBUS RTU

Temperature Range: -40~ 350 °C

How to select the Right Flow Meter for corrosion inhibitors

When choosing a micro PD flow meter for corrosion inhibitors, consider:

- Flow range –Provide your flow range to silverinstruments.com

- Chemical compatibility – Verify wetted materials resist degradation

- Pressure rating – Ensure the flow sensor exceeds max system pressure

- Minimum flow sensitivity – Must detect the lowest expected flow rate

- Certifications – ATEX for hazardous areas

-Output- what kind of output you want, digital output or analog outputs

Conclusion:

Small positive displacement flow meters provides unmatched accuracy in corrosion inhibitor flow measurement

For corrosion inhibitor injection systems, small positive displacement flow meters provide unmatched accuracy in high-pressure, low-flow conditions. Their robust design, resistance to harsh chemicals, and ability to measure tiny volumes make them the go-to solution for reliable, long-term performance.

By investing in a precision elliptical gear flow meter, operators ensure optimal inhibitor dosing, reduced chemical waste, and extended asset lifespan—delivering measurable ROI through improved corrosion prevention.