Biogas is mainly made up of methane(CH4), carbon dioxide(CO2) and a small amount of hydrogen(H2), carbon monoxide(CO) and hydrogen sulfide(H2S).

When choosing a biogas flow meter it is important to consider the following parameters.

Biogas flow rate either in standard or actual condition

Flow rate can be measured either in standard or actual form. In measuring the flow rate “N” means “normal” and this means that the volume of gas has been adjusted to some standard or “normal” temperature and pressure, usually 0 , 101.325 kPa. The actual flow rate is the actual volume of gas that passes a flow meter per unit time e.g. m 3 /hr.

The biogas flow rate can be measured using the

thermal flow meter,

gas turbine flow meter,

vortex flow meters and the differential pressure flowmeter among others.

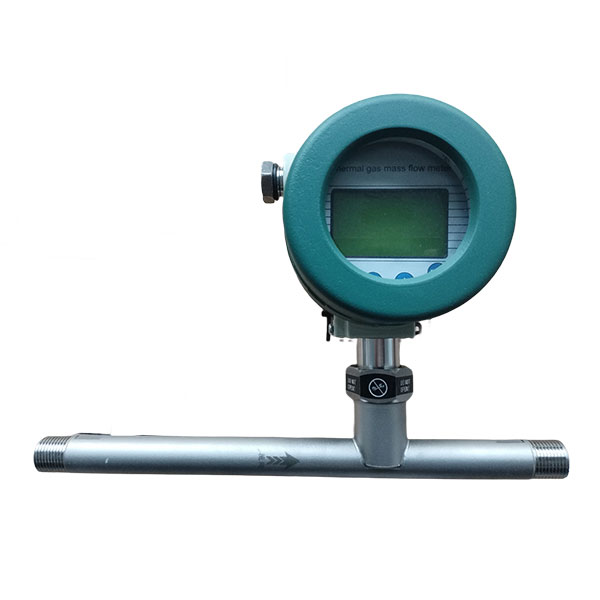

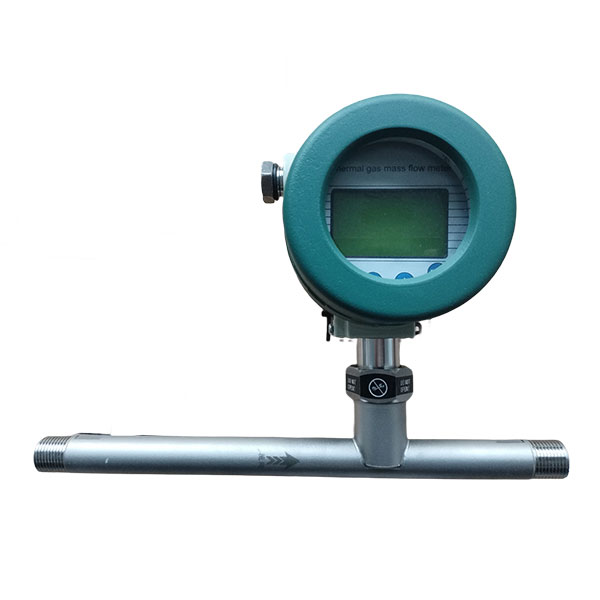

The thermal flow meter or

SGW-D series gas turbine flow meters are suitable for measuring the normal flow rate. While the vortex flow meter or SGW-C series gas turbine is suitable for measuring the biogas volumetric flow rate.

thermal biogas flow meter application

Flow range and pipe size

Biogas flow meter manufacturers need to determine the size of the gas flow sensor, which is generally determined by the flow range and the diameter of the pipe. The ideal state is that the selected flow meter diameter and the pipe size are the same, but due to the biogas flow rate, it may be possible to select a flow meter that is larger than the pipeline or smaller than the pipeline.

Flow meter

sensor size

DN (mm)

|

25

|

40

|

50

|

80

|

100

|

150

|

200

|

250

|

300

|

400

|

500

|

600

|

700

|

800

|

900

|

1000

|

1200

|

1500

|

2000

|

Biogas Flow range

(N m3/h)

|

51

|

129

|

206

|

516

|

860

|

1720

|

3440

|

5160

|

7430

|

13209

|

20640

|

29721

|

40454

|

52838

|

66873

|

82560

|

118886

|

185760

|

330240

|

below table we list thermal mass flow meter flow range corresponding flow range. Please verify that whether your flow range is within our flow meter range.

Flow meter process connection

It is also important to notify your manufacturer on the type of process connection you would love them to use. You can either go for an insertion type, flanged or even the wafer type of biogas flow meter.

Here we list some process connection for your reference.

Inline type Flange connection

|

Insertion type with ball valve

|

Insertion type with flange connection

|

Inline type screw connection type

|

Remote display type

|

Tri-clamp connection

|

Working pressure and working temperature

The biogas flow meter is designed to operate under pressure of 16bar. In case the biogas flow sensor detects pressure above 16bars you need to notify the flow meter supplier or the manufacturer.

Based on experience, biogas often operates under low pressure conditions, such as 1-2Kpa, and sometimes the flow rate is also very low. Thermal gas flow meters are particularly suitable for low-pressure and low flow rate operation.

The function of the Flow Meter

Another important aspect is how one intends to use the biogas flow meter, that is, the purpose of the flow meter. It can be used either for digital display, hart protocol, remote display, pulse output or 4-20mA output or even as RS4845 Modbus RTU.

Once you have figured out your main aim you should notify your supplier or manufacturer so that they can choose for you the best biogas flow meter that suits your needs.

To get the best biogas flow meter check out the Silver Automation Instrument which is a Chinese based supplying company.

Click below for more technical specifications of biogas flow meter: