Electromagnetic Flow meters are normally used flow measuring devices, after you ordered the flow meters, we will delivery the instruments to you , below is the precedures and instructions you need to do and follow after you receive the mag meters.

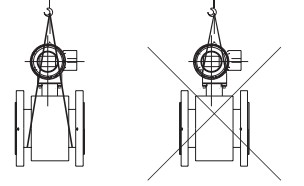

Please note that when delivering the instruments to the mounting field.Please use elevator belt when delivering flange type flow meter (≤DN 450 [18”]) and fix position with the two flanges. Chains are forbidden due to abrading the housings.

Warning!

The gravity center of the flow instrument may be higher than the lifting points of elevator belt. If the instrument slides, it will cause injuries! Please ensure that sliding and spinning will not appear during delivering.

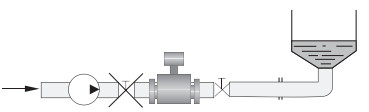

Figure 1: Size ≤DN 450 [18”] Flange type Flow meter delivering

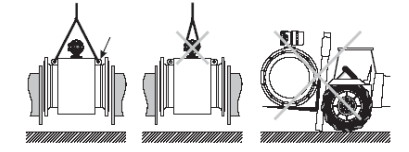

Size > 450[18”]Flange process connection magnetic flow meter delivering

Connection box cannot be used to lift the flow meter, using lift rings on the flow meters, and orient the flow meter into the pipelines.

Caution!

Do not move the flow meter using Fork lift, it can crush the housing and damage the internal coils.

Figure 2 : Size > 450[18”] Flange type Flow meter delivering

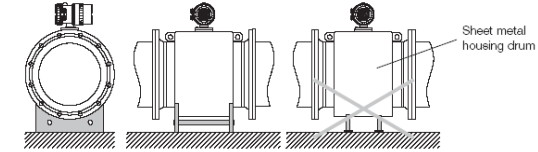

Size > 450[18”]Flow meter Base and Support

Flow meter should be put on the Base or Support

Caution!

Flow meter cannot orient by the housing, otherwise it will cause damage to the internal coils.

Figure 3 : Size > 450[18”] Flange type Flow meter Base & Support

The flow direction should match the arrow direction on the flow meter (if existing)

The flange bolts have been fasted to the max torque rating.

Mechanical stress (twist, bent) shouldn’t exist when mounting, mating flanges keep axial symmetrical and parallel, proper gaskets should be used.

Gaskets shouldn’t be extended to the flow area, otherwise whirlpool generated and affecting accuracy of the flow meter.

Any force and moment from the pipe shouldn’t affect the flow meter.

The display of the flow meter should face the users

Protecting plug of the cable entries are only allowed to be removed when wiring.

Remote type converter should be mounted on some place where is free from vibration.

Converter of the flow meter should be free from direct sun shine. (Shade is required)

Choosing the mounting place

Choosing the place where negative pressure in the pipe is avoided.

Choosing the place where no motors, no transformers are nearby, powerful electromagnetic ware may generate electrical interference.

When measuring mixed-phase medium, the flow meters shouldn’t be mounted on some place where the mixed –phase is separating.

When the environment temperature is between -25 °C~ + 60 °C, direct sun shine is better to be avoided.

Mounting the place where is free from vibration or little vibration, if strong vibration is existed, fix support is required before and after of the flow meter.

Temperature humidity should be within 5% ~9%

Direct raining and immersion is avoided.

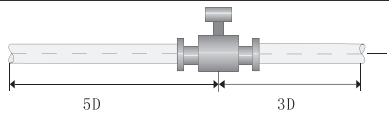

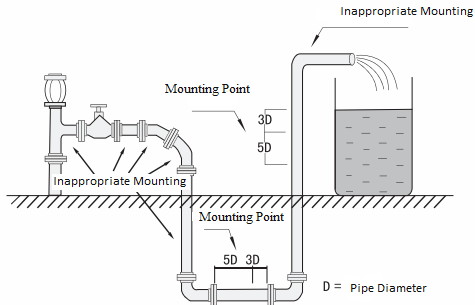

Electromagnetic flow meters have low requirement for the straight pipe before and after the flow meters, Flow resistance fittings such as 90° elbow ,T Fittings, reducers, full-open valve,etc should have the 5D distance from the axis of the electrodes (not plane of the sensors) ; 10D distance in the upstream is required if there is different opening valves(for example adjusting opening valve). Normally 3D straight pipe is required in the downstream of the flow meter.

(D is the inner diameter of the flow meter )

See following figure:

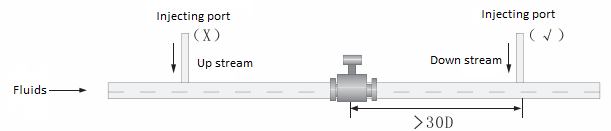

When measuring mixed medium, mixed points should have 30D distance from the flow meter, see following picture

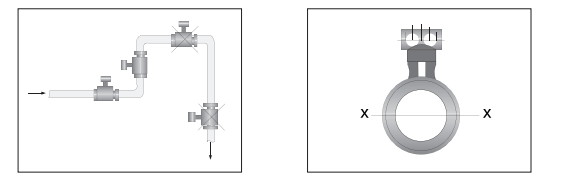

The Electromagnetic Flow meter can be horizontal, Vertical or slide mounted.

When horizontal mounting, the axis of the electrodes must be horizontal to avoid electrodes short time insulation generated from the bubble in the liquid, also avoid sediments covering electrodes. The sensor shouldn’t be mounted in the highest point to avoid air accumulation in the pipe.

When the flow meter is vertically mounted, the flow direction should be upwards, it can have following merits.

When there is no flow or small flow , the heavy solids in the fluids are down and the fatty substances are up to be away from the electromagnetic flow meter electrodes area. When measuring particle-liquid two phase fluids, such as slurry, pulp , vertical mounting can avoid uneven abrasion from the sediments. As the picture shows. The measuring pipe should be filled with liquid and back pressure should be existed.

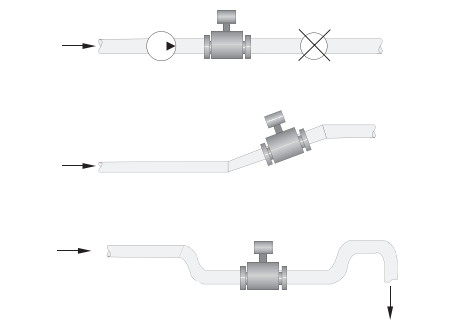

To avoid negative pressure (damaging the liners), the electromagnetic flow meter shouldn’t mount in the inlet of the pump, outlet is recommended. When sliding mounting the flow meter, the flow meter should be mounted in the going-up pipe;

When mounting the flow meter in the open discharging pipe, the meter should be mounted in lower place.

Control Valves and Stop Valves in the downstream (instead of upstream) of the sensors are recommends

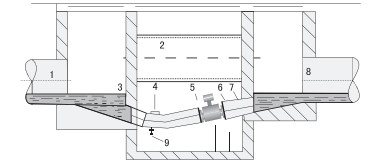

Method of mounting the flow meter in the well

|

1.Inlet 2.Over-Flow Pipe 3.Inlet 4.Clean Hole 5.Flow meter 6.Short Pipe 7.Outlet 8. Drain outlet 9. Drain Valve |