What is Soft Water & Why Measure Its Flow?

Soft water refers to water treated through ion exchange or reverse osmosis to remove hardness ions like calcium and magnesium, typically exhibiting conductivity below 50 μS/cm. Its industrial significance includes:

1. Anti-scaling Protection: Extends equipment lifespan (boilers, heat exchangers)

2. Process Stability: Ensures formulation accuracy in pharma & food industries

3. Environmental Compliance: Meets ion concentration standards for wastewater discharge

Key Industries Requiring Precise Soft Water Flow Measurement:

Pharmaceutical (purified water systems)

Food & Beverage (ingredient mixing)

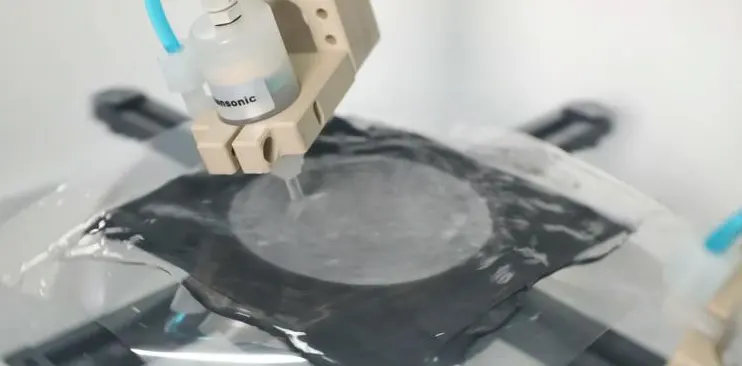

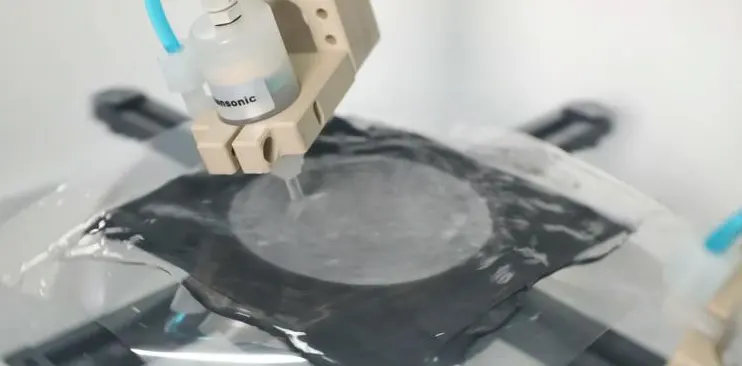

Microelectronics (wafer cleaning)

Chemical Processing (reactor cooling)

HVAC Circulation Systems

Comparative Analysis of Four Soft Water Flow Meter Technologies

# 1. Turbine Flow Meter for soft water

Operating Principle: soft water kinetic energy rotates a turbine, with flow rate calculated via magnetic/optical sensors detecting rotation speed.

Operating Principle: soft water kinetic energy rotates a turbine, with flow rate calculated via magnetic/optical sensors detecting rotation speed.

Advantages for Soft Water flow measurement:

✅0.5% accuracy

✅Full pipe size coverage (DN4-DN200) to cover different pipelines and flow range, normal request is 1/2” RO flow meter, 1” water flow meter, 2 inch OR water, 3 inch water flow meter and so on.

✅Measures 0.3-10 m/s flow velocities

✅Stainless steel material for soft water measurement

✅

Low price cost water flow meter

✅Digital soft water flow meter with digital display, 4-20mA ,pulse output, option with MODBUS RTU.

Limitations:

-Sensitive to particulates (requires 100μm filter), liquid turbine flow meter can only measure clean liquid without particles.

-Mechanical wear affects long-term stability, because it has moving parts inside the turbine flow sensor.

# 2. Vortex Flow Meter

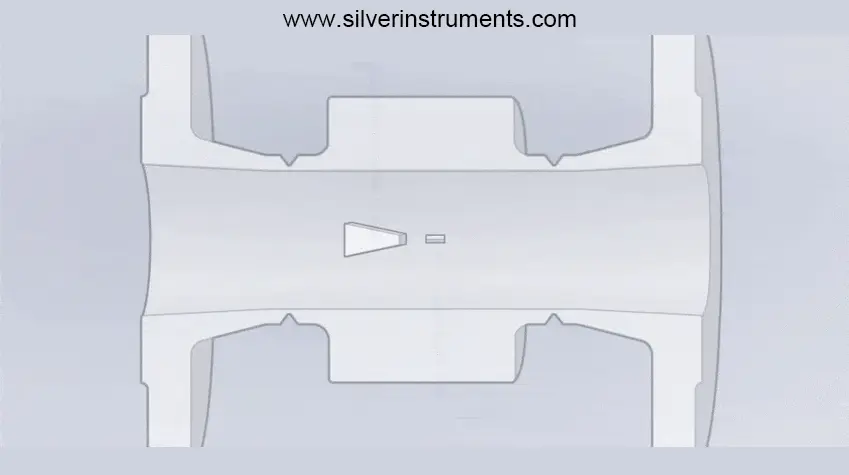

Working Principle: Utilizes Kármán vortex street effect, calculating flow via detected vortex shedding frequency.

Working Principle: Utilizes Kármán vortex street effect, calculating flow via detected vortex shedding frequency.

Vortex flow meter for soft water measurement Performance:

✅No moving parts (low maintenance)

✅Can make into high pressure water flow meter, for example withstands 6.3MPa pressure

✅Broad temperature range (-40°C~350°C) for vortex flow sensor

✅All

stainless steel flow sensor made material of stainless steel 304 ,316 or 316L

✅Can be made into 24V DC or battery operated flow meter.

✅Can make into different process connection, such as flange, tri-clamp sanitary flow meter, screw connection and so on.

Tri-clamp connection soft water flow meter

Tri-clamp connection soft water flow meter

Constraints:

-Reduced accuracy below 0.5 m/s ,and normal accuracy for water measurement is 1.0%

-Requires 10D upstream & 5D downstream straight pipes

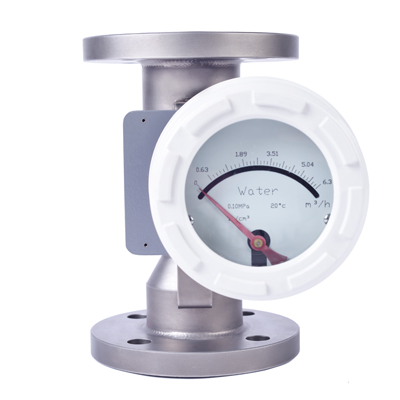

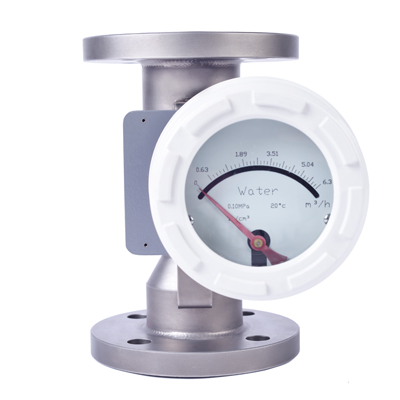

# 3. Rotameter

Mechanism: Float position in tapered tube corresponds to flow rate, enabling visual reading.

Mechanism: Float position in tapered tube corresponds to flow rate, enabling visual reading.

Benefits for Soft Water rotameter flow meter:

✅Visual monitoring for water flow rate.

✅Cost-effective flow meter for RO water (40%-60% savings)

✅Rotameters have a long history and stable working performance

✅Local monitoring capability no external power

Local monitoring rotameter without power supply

Drawbacks:

-2%-5% accuracy (unsuitable for custody transfer)

-Vertical installation normal , and horizontal mounting will cost a lot money

-Suitable for low flow soft water flow measurement

# 4. Coriolis Mass Flow Meter

Core Technology: Measures phase shift from Coriolis forces in vibrating tubes to determine mass flow.

Core Technology: Measures phase shift from Coriolis forces in vibrating tubes to determine mass flow.

Advantages using Coriolis flow meter to measure soft water mass flow

✅±0.1% ultra-high precision, it is high accuracy flow meter

✅Multi-parameter output,beside measure software mass flow rate and total flow , it can also measure RO water density/temperature .

✅Immune to conductivity variations

✅Various flow range options, for example from 40 g/h , to 1 t/h, to 10 t/h, Silver Automation Instruments all have solutions for different flow range and pipeline sizes.

Mass water Flow Range corresponding to different size mass flow meter:

|

Inch

|

3/8”

|

1/2”

|

3/4”

|

1”

|

1.5”

|

2”

|

2.5”

|

3”

|

4”

|

5”

|

6”

|

8”

|

8”

|

10”

|

12”

|

|

DN(mm)

|

10

|

15

|

20

|

25

|

40

|

50

|

65

|

80

|

100

|

125

|

150

|

200A

|

200B

|

250

|

300

|

|

Flow Range

|

0~1.5 T/h

|

0~3 T/h

|

0~7 T/h

|

0~13 T/h

|

0~22 T/h

|

0~33 T/h

|

0~60 T/h

|

0~100 T/h

|

0~160 T/h

|

0~230 T/h

|

0~300 T/h

|

0~400 T/h

|

0~500 T/h

|

0~800 T/h

|

0~1500 T/h

|

Notes:

Coriolis is a High cost flow meter, comparing to the cost of turbine flow meters (TUF), vortex flow meter and rotameters. Water mass flow sensor is sensitive to vibrations .

When discussing water flow measurement, electromagnetic flow meters (magmeters) instinctively come to mind as the go-to solution. These

full-bore flow meter devices offer non-intrusive operation with zero flow obstruction and cost-effective pricing. However, their application proves fundamentally problematic for soft water measurement due to inherent technical constraints.

Electromagnetic flow meters (magmeters) operate via Faraday’s Law, requiring conductive fluids (>5 μS/cm). Soft water’s low conductivity (<50 μS/cm) causes:

1. Signal Attenuation: Reduced electromotive force degrades SNR

2. Zero-point Drift: Electrode polarization in low-conductivity media

3. Measurement Errors: ±5%+ deviations vs. turbine meters’ ±0.5%

Market Trends for soft water flow meter.

The global soft water flow meter market reached $1.2B in 2023, with Coriolis flow meter multi-parameter devices growing at 8.7% CAGR (Flow Research). IIoT-enabled smart flow transmitters featuring Modbus/Profibus PA protocols now dominate, offering predictive maintenance for bearing wear (turbine flow meter) or vibration anomalies (vortex flow transmitter).

Operating Principle: soft water kinetic energy rotates a turbine, with flow rate calculated via magnetic/optical sensors detecting rotation speed.

Operating Principle: soft water kinetic energy rotates a turbine, with flow rate calculated via magnetic/optical sensors detecting rotation speed.

Working Principle: Utilizes Kármán vortex street effect, calculating flow via detected vortex shedding frequency.

Working Principle: Utilizes Kármán vortex street effect, calculating flow via detected vortex shedding frequency.

Tri-clamp connection soft water flow meter

Tri-clamp connection soft water flow meter

Core Technology: Measures phase shift from Coriolis forces in vibrating tubes to determine mass flow.

Core Technology: Measures phase shift from Coriolis forces in vibrating tubes to determine mass flow.