There are various structure of Vortex Flow meter, installing & maintenance person should know very well of vortex flow meter structure, features and flow signal conversion and install according to manual to ensure meter measuring accuracy.

Avoid vortex shedding flow meter with strong power electrical, high frequency and strong power switch; avoid affected by high heat resources and radiation; avoid location with strong vibration and corrosive ambient etc, meanwhile, consider of convenient maintenance.

To ensure fluid section not being affected, vortex flow transducer should be installed downstream any location that can cause fluid disturbing (such as diverging pipe, converging pipe and valve). The longest straight pipe should be used between flow resistance part and flowmeter. If there are two or more flow resistance parts at upstream of flowmeter, the straight pipe should be much longer.

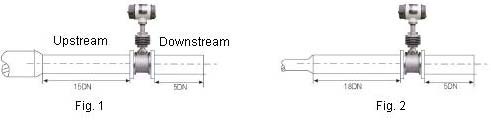

The length of straight pipe ≥ 15D for upstream and ≥5D for downstream if converging pipe >15°is used in upstream of transducer installing site (shown as Fig. 1).

The length of straight pipe ≥ 18D for upstream and ≥5D for downstream if diverging pipe>15°is used in upstream of transducer installing site (shown as Fig. 2).

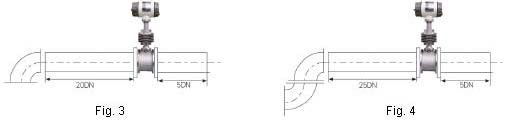

The length of straight pipe ≥ 20D for upstream and ≥5D for downstream if 90°elbow or T joint is used in upstream of transducer installing site(shown as Fig. 3).

The length of straight pipe ≥ 25D for upstream and ≥5D for downstream if two 90°elbows on same plane in upstream(shown as Fig. 4).

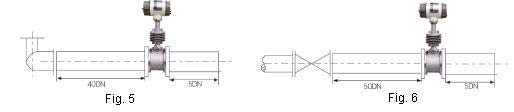

The length of straight pipe ≥ 40D for upstream and ≥5D for downstream if two 90°elbows on different planes in upstream(shown as Fig. 5).

Flow or pressure control valve should be installed at least 5D far away from the meter in downstream as possible, if these valves must be installed in the upstream, ensure ≥50D for upstream at least and ≥5D for downstream(shown as Fig. 6).

The inside diameter of companion pipe for upstream and downstream should be the same as nominal diameter of flowmeter, and should meet requirements as below:

0.98DN≤ D ≤1.05DN

Thereinto: DN----------nominal diameter of the flowmeter

D-------------inside diameter of the companion pipe

Vortex flow meter Sealing gasket between flange and transducer cannot be protruded into the pipe, and its ID can be slightly bigger than that of transducer.

4. Requirement for Pipe Vibration

Avoid vortex flow transducer being installed on the pipe with strong vibration, if you have to installed, vibration damping measures should be taken. Install fitting device at 2D far away from the flowmeter on both side of upstream & downstream and vibration pad should be used too.