(1) The origin of flow measurement

The clepsydra and water clock used for timekeeping in ancient times are devices that use the constant flow technology to calculate time. The oldest clepsydra in the world is the Egyptian water clock from the 14th century BC. In our country, the Forbidden City has a copper kettle water clock from the Western Han Dynasty (206 BC to 8 AD). In 3000 BC, people tried to measure the flow of the Nile River by measuring the water level for agricultural cultivation. From then on, it became possible to calculate the distribution of water. This can be said to be the origin of flow measurement.

The anemometer was invented in the 16th century, the velocity meter for open channels in the 17th century, and the Pitot tube in the 18th century, which laid the foundation for the development of flow measurement technology. In the same period, the most basic equation of fluid mechanics, the Bernoulli equation, was established.

Pitot tube for fluid flow velocity measuring

However, the real f

low measurement started in the 19th century when the prototype of the commercial supply network of water and gas was formed. In order to meet the needs of trade, people designed wet gas meters, dry gas meters, water meters, diaphragm flow meters, Venturi flow meters, etc. for measuring water and gas. In the same period, Faraday's law, Reynolds number, law of conservation of energy and Karman vortex street experiment conducted by Strohal were developed. The science and technology of this period laid the foundation for the rapid development of flow measurement, but it should also be noted that the manufacturing process of flow meters in this period was still relatively rough, the understanding of related technologies was not clear enough, and the overall measurement level was at a low level.

(2) Development of flow measurement

Since the 20th century, with the rapid development of electronic technology, materials and processing technology, the development and improvement of flow meters have advanced rapidly.

With the prosperity of various industries, such as process industry, and public utilities, such as water supply and gas, the flowmeter has become more and more popular.

The amount and areas of using have expanded rapidly. The main mechanical flowmeters now were developed during this period, such as various forms of orifice plates, rotameter flowmeters, triangular weirs and other forms of weir flowmeters, slot flowmeters, etc. in the first half of the 20th century. The practical application of electromagnetic flowmeters is a very outstanding progress. It is not only used for round pipe flow measurement, but also has been applied in a wide range of flow rates from rivers to blood.

Like other industrial technologies, the second half of the 20th century was a stage of great development for flow measurement instruments. During this period, because flow measurement was widely used, and because the fluid being measured was complex and the measurement conditions and environments varied widely, the requirements for flow meters varied. Therefore, in order to adapt to different medium conditions, different environmental conditions, and different usage requirements, various flow measurement instruments have emerged. According to incomplete statistics, there are dozens of commonly used types of flow meters. It can even be said that as long as there are new technologies developed, people will try to apply them to flow measurement, such as thermal flow meters, modern electromagnetic flow meters, ultrasonic flow meters,

mass flow meters, vortex flow meters, jet flow meters, and related flow meters.

In China, water flow meters and gas flowmeters were produced independently in the 1950s, and the development and stable quality of products were achieved in the 1990s. In general, the manufacturing level of flow meters in my country is still far behind the world's advanced level, especially in the bearings of turbine flow meters, the materials and processes of mass flow meters, and the processes of ultrasonic flow meters.

Entering the 21st century, multi-channel ultrasonic flowmeter technology has achieved new developments and has been applied in the fields of industrial measurement and metrology verification with its incomparable advantages.

(3)The future of flow measurement

With the increasing demand for trade settlement, energy measurement and environmental protection are gradually being paid attention to, and the improvement of industrial production quality, efficiency and cost control targets have put forward higher requirements for the quantity, accuracy and reliability of flow meters. The main technical improvements are concentrated in the following aspects.

(1) The manufacturing level of flow meters continues to improve

Improvements in flowmeter structure, materials and processing technology have made high-accuracy flow measurement possible, and the long-term operating reliability of the flowmeter has also been significantly improved as an important indicator. For example, the improvement of the bearing material and process of the turbine flowmeter has greatly improved its ability to operate stably in the long term; the improvement of the material and processing technology of the mass flowmeter has not only reduced the production cost, but also improved its metering performance.

(2) Flow meter calibration technology is gaining attention

With the improvement of flow meter measurement accuracy, people gradually realize that the accuracy of flow calibration devices is the basis and guarantee for accurate flow meter measurement. The improvement of calibration devices has become an important part of flow measurement. It has been highly valued in recent years and the technical level of the devices has been greatly improved.

(3) Research on the impact of installation and use conditions

The metering performance of the flowmeter calibrated in the laboratory may drift when it is used in the field, because the laboratory conditions are very different from the field conditions. Therefore, relevant research on the differences of using flowmeter conditions has been gradually carried out, including the influence of straight pipe section, the influence of three-installation condition position, the influence of medium change, the influence of vortex flow, the influence of environmental conditions, etc. In addition, the performance of the supporting instrument is also improved and gradually paid attention by people.

(4) Development of non-real flow calibration technology

With the increasing demand for large-diameter flow measurement and the development of ultrasonic flow measurement technology, the demand for large-diameter flowmeter is becoming more and more urgent, but the size of the calibration device is limited after all. Under such a background, the non-real calibration technology of large-diameter flowmeter has developed rapidly. This technology is achieved by combining computational fluid dynamics, model experiments and field experiments.

Flow Calibration Technology is also developing all the time

Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.view

Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.view Thermal mass flow meters2025/04/30Thermal gas flow meters with factory pricing from China – accurate, stable, and ideal for air, NG, CO₂, N₂, biogas, LPG/CNG.view

Thermal mass flow meters2025/04/30Thermal gas flow meters with factory pricing from China – accurate, stable, and ideal for air, NG, CO₂, N₂, biogas, LPG/CNG.view Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...view

Liquid mass flow meter-Coriolis flow meter2020/02/19The Coriolis flow meter is widely regardedas the most accurate and highest-tech liquid mass flow meter on the markettoday. Applicable across a wide variety of industrial and municipal venues, theCorio...view Ultrasonic Flow Meter2017/04/12Non-contact flow meter

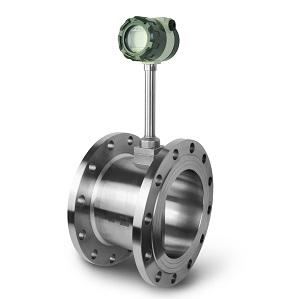

Ultrasonic Flow Meter2017/04/12Non-contact flow meter Vortex flow meter for natural gas2020/02/02What Is Natural Gas?Natural gas is a combination of gases thatexist rich in hydrocarbons. Natural gases such as methane, nitrogen, and carbondioxide also found in the air. Natural gas reserves are dee...view

Vortex flow meter for natural gas2020/02/02What Is Natural Gas?Natural gas is a combination of gases thatexist rich in hydrocarbons. Natural gases such as methane, nitrogen, and carbondioxide also found in the air. Natural gas reserves are dee...view Metal Tube Rotameter2017/04/12HH5 Variable Area flow meter is Metal Tube Rotameter, get price now for digital rotameter,flow indicator rotameter.view

Metal Tube Rotameter2017/04/12HH5 Variable Area flow meter is Metal Tube Rotameter, get price now for digital rotameter,flow indicator rotameter.view