Related Products

Ultrasonic Level Meter OverviewHL Ultrasonic level meter is non contact liquid level sensor for liquids and solids level measurement. Ultrasonic sensor consists...

Digital Capacitive Pressure Transducer.High accuracy 0.1%, 0.2%.Dp, absolute pressure ,gauge pressure.Range: 0-20 Mpa (2900 PSI).

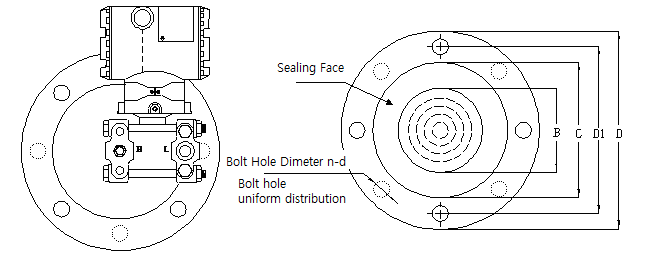

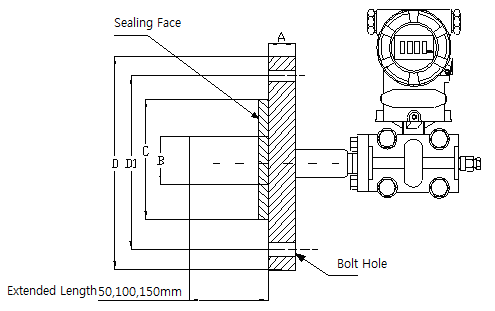

SHLT (smart) flange type capacitive level transmitter can carry on accurate measurement of level and density for all kinds of containers. It is a kind of pressure level sensor .Flush flange and extended flange available, 3" or 4", 1501b or 3001b flange, custom-made flange option.

Flange Specification

|

No. |

Flange size |

Bolt Hole |

Rated Pressure Mpa |

||||||

|

Flange size |

OD D(mm) |

ID B(mm) |

Seal face C(mm) |

Thickness A(mm) |

No. n |

Diameter d(mm) |

Bolt Circle D1(mm) |

||

|

1 |

2”150LB |

152 |

48 |

92 |

18 |

4 |

19 |

121 |

2.5 |

|

2 |

2”300LB |

165 |

48 |

92 |

21 |

4 |

19 |

127 |

5 |

|

3 |

3”150LB |

190 |

66 |

127 |

22 |

4 |

19 |

152 |

2.5 |

|

4 |

3”300LB |

210 |

66 |

127 |

27 |

8 |

22 |

168 |

5 |

|

5 |

4”150LB |

229 |

89 |

157 |

30 |

8 |

19 |

190 |

2.5 |

|

6 |

4”300LB |

255 |

89 |

157 |

32 |

8 |

22 |

200 |

5 |

|

7 |

DN25(PN2.5/4.0) |

165 |

48 |

92 |

21 |

4 |

22 |

125 |

4 |

|

8 |

DN80(PN2.5/4.0) |

215 |

66 |

127 |

24 |

8 |

|

160 |

4 |

|

9 |

DN100(PN2.5/4.0) |

235 |

89 |

157 |

28 |

8 |

22 |

190 |

4 |

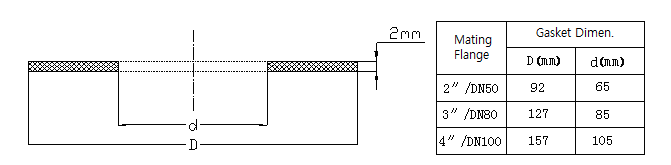

Flange sealing gasket Dimension

Flange sealing gasket material can be selected according to the measured medium, there are asbestos rubber, acrylonitrile-butadiene rubber, fluororubber, nylon,PTFE to be selected.

Model Selection

|

A |

S |

Code (Single Flush Flange) |

Measuring range |

Code (Single Extended flange) |

Measuring range |

||

|

Analogue |

HART |

SHLT-3310 SHLT-4410 SHLT-4510 SHLT-4610 SHLT-4710 |

0-1.2-7.2kPa 0-6-36kPa 0-30-180kPa 0-160-1000kPa 0-400-2500kPa |

SHLT-3330 SHLT-4430 SHLT-4530 SHLT-4630 SHLT-4730 |

0-1.2-7.2kPa 0-6-36kPa 0-30-180kPa 0-160-1000kPa 0-400-2500kPa |

||

|

*Code |

Flange Specification |

Code |

Extended Length |

||||

|

A B C D E F G H I J |

3 ” 1501b 4 ” 1510b 3 ” 3001b 4 ” 3001b 2” 1501b 1” 1501b DN50 1.6Mpa/4Mpa DN100 1.6Mpa Special design |

A0 B1 C2 D3 |

0 mm 50 mm 100 mm 150 mm |

||||

|

Code |

Display |

||||||

|

M1 |

Linearity indicator 0-100% scale mark |

||||||

|

M2 |

Digital indicator |

||||||

|

|

Code |

Diaphragm material of high side flange |

|||||

|

|

K1 |

316L |

|||||

|

|

K2 |

Hastelloy C 276 |

|||||

|

|

K3 |

Tantalum (Only for flush flange) |

|||||

Optional components

|

Code |

Mounting Bracket |

|

B1 |

Bend bracket for pipe mounting (2” pipe) |

|

B2 |

Bend bracket for plate mounting |

|

B3 |

Flat bracket for pipe mounting (2” pipe) |

|

Code |

Position of exhaust/vent valve |

|

D1 |

Side exhaust/vent valve of flange on top |

|

D2 |

Side exhaust/vent valve of flange at bottom |

|

Code |

Process Connection |

|

G0 |

NPT1/4 (F) |

|

G1 |

NPT 1/2(F) Waist type flange |

|

G2 |

NPT1/2-M20*1.5-Φ14 Welding pipe connector |

|

G6 |

M20*1.5(M) T-shape connector |

|

G7 |

M20*1.5(M) -Φ14 Welding pipe connector |

|

Code |

Process flange O-Ring material |

|

O1 |

Process flange O-Ring material: Nitrile rubber |

|

O2 |

Process flange O-Ring material: PTFE rubber |

|

Code |

Hazardous Area |

|

d |

Explosion separation type ExdsII BT5 |

|

i |

Intrinsically safe ExibII CT5 |

*Flange Selection Code Example:

For example, 3”, 150LB Flange with 50mm extended length, the selection codes should be BB1

we will contact you within 24 hours.