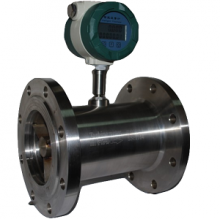

Electronic turbine flowmeter for gas

Turbine gas meters are rugged and designed to operate with the highest precision (1.0~1.5% gas measurement accuracy). All of these turbine meters (TUF) comply with all international standards and are approved quality before leaving gas turbine flow meter factory with the shortest possible installation length. Eletronic gas turbine flow meter not only with digital outputs but also with digital display. It is electronic gas metering device suitable for gas, biogas, natural gas, N2, O2, helium (He) gas, Ethylene (C2H4) gas ,carbon dioxide (CO2),methane gas, butane, propane, CNG, compressed natural gas, air, volumetric flow measurement.

Gas turbine flowmeter is actually a device used to detect the gas flow rate and flow in the gas pipeline in a closed state, and it is a typical velocity flow meter. Electronic gas turbine flowmeter has LCD indicator to show gas flow rate and gas totalized flow, battery operated gas flow meter or 24 VDC loop power. Digital gas flow transmitters have 4-20mA analog output, pulse output or MODBUS RTU communication or HART Protocol for various control and remote purpose.

Digital gas turbine flow meter standard pressure rating is 16 bar, can also be made into 300PSI, 300LB ,600$ high pressure gas turbine flow meters;

Digital gas turbine flow meter has option for built-in temperature RTD and pressure sensor compensation and correction. (EVC)

Electronic gas turbine flow meter normal request size:

1 inch gas flow transmitter, air flow range: 42-420 lpm

2”,DN50 gas turbine flow meter measurement range: 10- 100 cubic meters per hour,

3 inch, 80mm size gas flow meter: 5.5-111 L/s,

4” ,DN100 electronic gas turbine flow meter can detect 20-400 m3/h,

6”, DN150 digital gas turbine flow meter, 50-100 m3/hour,

8 “DN200 gas flow meter, 80-1600 m3/h

10” 250mm dial size gas turbine flow meter. 200-4000 m3/h

12 inch electronic gas turbine flow meter can measure gas range: 188-3825 cfm

Turbine Flow meter for liquid

Turbine flow meters use the mechanical energy of the liquid to rotate a rotor in the flow. The speed of rotation is proportional to the velocity of the fluid flowing through the meter. These electronic meters are used in multiple industries to reliably measure clean and not corrosive liquid, such as condensed water, RO water, tap water turbine meter, distilled water, portable oil,milk,acetic acid, Palm Olein oil, diesel, biodiesel liquid turbine flow meter , ethyl alcohol, petrol, vegetable oil ,edible oil, coconut oil, kerosene,jet fuel,fuel oil flow meter, Toluene, Xylene, ACETONE, Toluene ,Butyl acetate liquid turbine flow transmtters ,etc

Silverinstruments offers industry-leading liquid flow measurement turbines with a broad range of products, accuracy and impressive temperature operating ranges.

Electronic turbine flow meter for liquid measurement has pulse NPN,PNP, frequency, and analog 4-20mA output,HART , MODBUS for long distance signal transmission.,etc

Turbine flow meter has digital indicator options to read liquid measurement directly, also easy for parameters configurations with local keys and buttons.

Various turbine sensor size , such as low flow turbine flow meter 1/8” , micro turbine flow meter 1/4”,3/8 inch, 1/2 inch turbine water meter, 3/4 inch liquid turbine flow meters, 1 inch, DN50,3 inch ,80mm dial size , 4 inch water turbine meter, 5 inch, 6 inch turbine meter, 8 inch liquid turbine flow sensor , 10” ,12inch,DN300 turbine flow meters.

Stainless steel flow meter with SUS 304 or stainless steel 316 options;

Battery powered electronic turbine flow meter by 3.6V lithium battery, 24 VDC or 220V AC;

Various connections options: wafer liquid turbine flow meter, screw NPT or BSP connection, tri-clamp or tri-clover hygienic and sanitary turbine flow meter, flanged connections with ANSI, JIS or DIN standard;

Turbine flow meters are volumetric in-line sensor to detect gas or liquid flow rate; it detects low to middle flow rate, clean, low corrosive and viscosity fluids. Turbine flow metre is divided into gas turbine flow meter and liquid turbine flow meter. Silver Automation Instruments supply

electronic turbine meter with a variety of outputs, such as frequency, current for PLC or batch dispensing operation. It can take measurement of fuel, gasoline, diesel, water, RO water, milk, natural gas, biogas, compressed air and so on.

It is operated with simple well understood technology; measured medium is going to the sensor body, making the rotor to rotate at a speed proportional to medium velocity and flow rate. As each blade passes through the magnetic field generated by the flow meter’s magnetic pickup, an alternating current voltage pulse is produced.

Features of LWGY Turbine flow meter

✔ Stainless steel flow meter

✔ High accuracy

✔ Low price cost

✔ Variable sensor size available, such as 1 inch, 2 inch, 3 inch, 4 inch turbine flow meter

✔ Rugged quality and small compact design for easy mounting

✔ Fast response time

✔ Can work for conductive or non-conductive liquid

✔ Many process connection available: thread, wafer, flange, tri-clamp

sanitary turbine flow meter for hygienic industry

Flowmeters works in various ways and it measures different elements. Therefore,in this article i have provided everything that will help you to understand more about turbine flowmeter. The design is comprehensive and it will help you to get more insight about its funtionalituy. Read on and find out.

turbine flow meter working?

There is a shaft that is mounted inside

inline turbine flow meter to support the other. This helps in minimizing negative turbulence attack. The support provided also houses the open bearings which allow for lubrication of the brushes hence prolonging the lifespan of the turbin flow meter. These supports have locking rings that are used to fasten it.

The shaft plays a crucial role in supporting the rotor. Therefore, when there is a flow it induces a force on rator wings which will, in turn, rotate because its shape and angle enhance force. Additionally, there is a mounted

turbine flow transmitter above the rotor which generated signals for passing blades. The sensors located externally to the glowing stream to avoid the occurrence of constraints in a case whereby wetted sensors are used. The pulse signal which is processed by the flow transmitter is used in determining the flowrate of the liquid or gas. The sending and transmitter systems sense the forward flow directions.

The most important element that keeps it to move freely is the propeller located in the tube. This turbine flowmeter has been designed to ensure there is little drop in pressure hence it is regarded as one of the best measurement tools.

Pros

-High accuracy

-The cost is moderate and low price

-It is reliable performance

-Very good at clean fluids measurement

-Turndown is impressive

Cons

-Bearings wearing out

-It is not reliable when measuring steam

Turbine flow meter price

Turbine flow meter price is determined by many factors

a. Gas turbine or liquid turbine flow meters are different

b. Different turbine flow meter sensor size ,different price

c. Different turbine flow transmitters, different cost, such as whether need digital turbine flow meter , whether need HART or RS485.

d. High temperature or high pressure also affect turbine flow meter price a lot

Turbin meter Manufacture

There are many top brands turbin flow meter factories,

such as cameron nuflo turbine meter,blancett flow meter,daniel

turbine meter,omega turbine flow meter,badger turbine meter,helical

turbine meter,Emerson turbine flow meter,k24 electronic turbine

meter, they are rugged turbine flow meters with not cheap price .However

Silver Automation Instruments sell economical flow meters as alternative or low

price replacement.

turbine flow meter accuracy

SGW Gas turbine flow meter with accuracy 1.5% or 1.0%,liquid turbine flow meter with accuracy 0.5~1.0%

How to operate

It takes flow measurements on velocity of gases and liquids. A functionality flow computer can be used to correct the temperature, pressure and fluid properties that ensure the desired accuracy is achieved. Non-lubricating fluids can wear out its bearing and it influences the flowmeter to lose its accuracy levels. However, some have grease fittings that allow them to be used with non-lubricating fluids. Additionally, these turbine Flowmeters are designed to operate with a limited temperature range of up to 60 c which implies it is susceptible to being damaged when exposed to a temperature that exceeds this value.

It is used for liquids up to 10 inches (

DN250 Turbine flow meter). The weight and the size of a larger turbine might require supports and concrete foundations.. When dealing with corrosive fluids Attention should also be paid to materials, such as fittings, bearings, rotor, and body.

Chemical, petroleum and water industries largely use turbine Flowmeters. Some chemical, food, and beverage industries can also use this type of Flowmeters. It serves custody of the transfer of hydrocarbons in the petroleum industry and a distribution system for water plants. We often use this flow instrumentation as

natural gas flow meter, diesel flow meter,

fuel flow meter.,etc

Industries where turbine flow meter used

Turbine Flowmeters are used in the following industries as per the largest to the smallest magnitude.

-Oil and gas

-Water and wastewater

-Gas utility

-Chemical

-Power

-Food and beverage

-Aerospace

-Pharmaceutical

-Pulp and paper

Application and Risks

The accuracy is compromised at slow flow rates. Therefore, there is a need to ensure the flowmeter is operated at above 5 %. High speeds can also lead to wearing out. Non-lubricating fluids can also make it less accurate that is why you should be cautious enough to avoid such inconveniences. It should also not be used I dirty fluids to reduce occurrences of bearing damage.

It can get damaged or become less accurate when there is an abrupt transition from gas to liquid flow. This scenario can occur when it is under slug flow or filing the pipe. You should also avoid two-phase flow because there will be inaccurate measurements. Gas turbine flow meter and liquid turbine flow meters are different, customers should specify the fluids when buy the turbine flow meter to the manufacture.

If you are unfortunate enough to experience some breakdowns with your flowmeter you need to choose replacements wisely. You should look at the levels of accuracy that you need. It is better to settle on an expensive but reliable system.

Lastly, before you purchase ensures it has a warranty in case of unexpected breakdowns. Most cases that have led to breakdowns is using it the wrong way. As I had earlier said that Non-lubricant are kit recommended because it makes this system to lose its accuracy. Therefore,it is important to use it for the right purpose to ensure you get reliable and accurate results.