Micro flow meter for liquid

LC-M Series Micro flow meter is a kind of positive displacement flow meter, it can detect ultra mini liquid flow as low as

0.5 ml/min , but can still keep accuracy as high as 0.5%F.S.It is a kind of micro PD flow meter for precise flow measurement of mini or low flow liquid, the

micro flow meter can take flow measurmenet liquid include water, diesel, fuel,lubricant,petrol, oil, chemical, sealant, toluene, glue, detergents, grease, electrolyte, ethylene, additive, syrup, acryiat-composite.,etc . It is widely used in hydraulic system, lubricating industry and painting industries for fluids low-flow rate measurement.

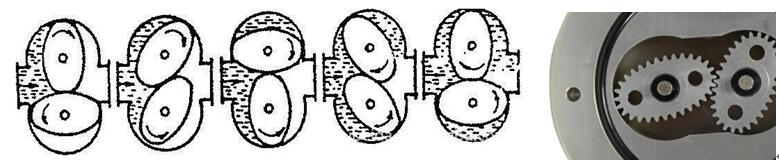

LC-M Series Micro flow meter Principle

There is a pair of gears meshing with each other as rotors in the cavity of the micro flowmeter, and the two gears and the chamber respectively form a fixed volume. Liquid flow is measured by calculating the number of flow through the standard volume within a certain period of time.

Micro flow meter liquid applications

This kind micro flowmeter is mainly used in adhesives and polymers, but can also be used in many basic fluids, such as in the water industry and in hydraulic testing. For example, a manufacturer's products can be used in solvents, pigments and adhesives, dispersants, polymers, polycondensates, glucose, organic-inorganic solutions, enzyme solution,gasoline, fuel oils, lubricants, raw or intermediate liquid products, and other liquid chemicals.

Low flow flow meter Technical Specifications

-

High accuracy: +/-0.5FS

-

LC-M micro flow meter is suitable for liquid within 2000 mPa.s viscosity, can be made into high viscosity micro flow meter;

-

Fluids temperature: -30~80°C,optional high temperature to 250 °C

-

Operation pressure: Standard 725 PSI, max 14503 PSI;

-

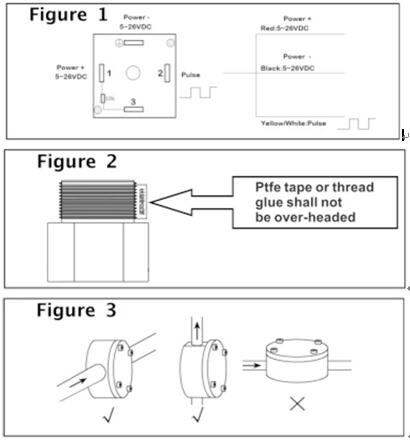

Output: Hall pulse output, NPN or PNP,digital micro flow meter;

-

Max frequency: 0.03 ml/p

-

Power supply: 4-26V DC

-

Process connection: Thread

-

Material: stainless steel 316L or aluminum or PPS

-

Suitable for pipeline: 3/8",1/4 in,1/2inch,3/4",1 inch;

Micro flow meter flow liquid range table:

-

LC-M2 Flow Range:0.5-150 ml/min

-

LC-M5.2 Flow Range: 1-400 ml/min

-

LC-M5.1 Flow Range:1~800ml/min

-

LC-M6 Flow Range: 0.5~100 L/H

-

LC-M9 Flow Range: 6~600 L/H

-

LC-M12 Flow Range: 0.3~30 L/min

-

LC-M25-AL Flow Range: 0.5~100L/min

Install of low flow micro liquid flow meter

-

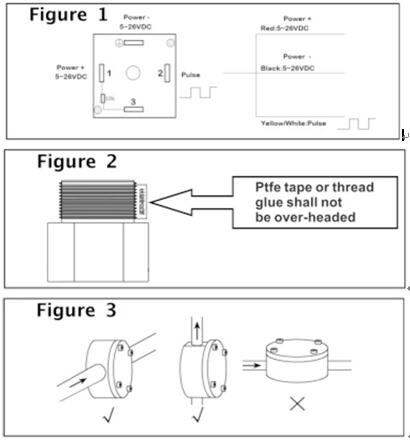

Pipeline cleaning requirements:Thoroughly clean the pipe before installation and install a filter in front of the micro liquid flowmeter (recommended debris from 200mesh or more) to prevent entering the flowmeter. During the installation process, be sure to avoid dirt and impurities from entering the flow inlet end. Pay attention to the joint raw material belt.(Figure 2)

-

Installation direction requirements:Please keep the axle of gear paralleled with ground. It means to keep the cap of flowmeter vertical to the ground. For the measurement of ultra-small liquid flow, the best installation is down-in, up-and-out. Showed as below.(Figure 3)

-

Requirements for liquid flow direction: The microfluidic flowmeter shell should arrow pointing on the be in accordance with the direction of liquid flow in the installed pipeline.

-

For continuous liquid flow piping, a bypass valve should be installed for regular cleaning. Please prevent no debris flow into the low flow flow meter when checking other instruments that are installed.

-

Installation requirements for special liquids (easy to crystallize and solidify liquids)

-

It is recommended that the pipe sections before and after the low flow chemical flowmeter belong enough and take corresponding measures to avoid liquid crystallization of the pipe section where the flowmeter is located If the liquids is easy to crystallize, please take measures to avoid liquid crystallization in the section where the flowmeter is located.

-

When starting or stopping,the valve should be opened slowly to prevent sudden impact.

-

Backflow should be prevented in order to prevent false pulses.