1. Product Overview

The Pitoba Flow Meter is an averaging Pitot tube flowmeter designed for reliable measurement of gas, steam, and liquid flow in industrial processes.

It is especially suitable for harsh, dirty media such as flue gas, coke oven gas, blast furnace gas, and coal gas containing dust, tar, or other contaminants.

Typical measured media include:

- Gases: air (primary / secondary air), oxygen, hydrogen, dry gas, converter gas, blast furnace gas, producer gas, coke oven gas, natural gas, LPG, flue gas, chemical process gas, etc.

- Steam / vapor: superheated steam, saturated steam, wet steam, bidirectional steam.

- Liquids: water, partially filled water lines, wash oil, lean oil, light oil, tar, heavy oil, crude oil, corrosive liquids, paraffin, and process liquids.

The Pitoba Flow Meter has a simple mechanical structure and is easy to install. The sensor is inserted into the pipeline through a single opening (typ. Ø25 mm ~ Ø60 mm) and connected by welding or flange.

It supports a very wide pipe size range from DN20 up to DN8000.

2. Why Pitoba Flow Meter

Long-term industrial operation has proven the Pitoba Flow Meter solves challenges that are difficult for conventional flowmeters:

- Resists blockage and wear in primary air speed and air volume measurement in the power industry.

- Handles high-temperature, high-pressure, and high-velocity main steam measurement.

- Reduces fouling problems when measuring various industrial gases.

- Works in both very small and very large pipe diameters (20 mm to 8000 mm), and in low flow conditions.

- Supports hot tap / pressurized installation without shutdown.

- Allows online cleaning and dredging without stopping production.

- Can be used on non-standard pipeline cross-sections (square, rectangular, diamond, trapezoid, elliptical, triangular, etc.).

- Supports calibration and verification with multiple inspection devices.

- Capable of measuring high-viscosity media such as crude oil, tar, and heavy oil.

- Can still measure where straight-run pipe is insufficient.

3. Working Principle (Pitot Tube Technology)

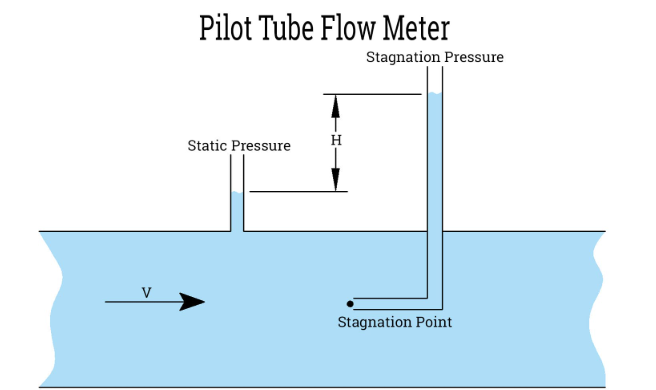

The Pitot-Bar operating principle is based on the Pitot tube.

The Pitoba Flow Meter is an averaging Pitot tube flowmeter. It is a differential pressure flowmeter designed according to ISO 3966 (Measurement of fluid flow in closed conduits — Velocity area method using Pitot static pressure tubes).

How it works:

- The sensor (Pitot bar) is inserted into the center of the pipeline.

- The total pressure port on the probe faces directly into the flow.

-

The sensor measures two pressures at the same location:

- Total (stagnation) pressure

- Static pressure

- The difference between total pressure and static pressure is the fluid dynamic pressure. This differential pressure is directly related to flow velocity at that point.

- The meter uses an averaging Pitot structure to establish a calibrated relationship between measured differential pressure and the average flow velocity of the pipeline cross section.

-

Flow rate is then calculated from:

- the average flow velocity, and

- the effective internal cross-sectional area of the pipe.

Because this is a differential pressure technology:

- A pressure transmitter is used to read differential pressure.

- A pressure sensor is used to read line pressure.

- A temperature sensor (e.g. RTD) is used to read fluid temperature.

These signals are sent to a flow computer or DCS system. The system performs temperature and pressure compensation and provides:

- differential pressure

- static pressure

- temperature

- instantaneous flow rate

- totalized flow

- velocity

- heat/energy (for steam)

This Pitot-tube-based principle is mature and trusted in aerospace. Pitot tubes are widely used in wind tunnel testing, aircraft engine aerodynamic testing, and even as airspeed probes on aircraft.

4. Performance Characteristics

-

Energy saving / almost no pressure loss

The Pitoba probe is typically made from stainless steel with a diameter under ~30 mm, so it introduces minimal obstruction into the pipe. Compared with traditional orifice plates and other throttling elements, pressure loss is extremely low, reducing operating cost. -

High temperature and high pressure capability

The probe is made from stainless steel 304 / 316 or special alloys depending on the medium. It can operate up to 650 °C under standard configuration, and up to 800 °C or higher with special designs (ceramic coatings such as Al₂O₃). Pressure ratings up to 25 MPa are standard and up to 32 MPa are available for special applications. -

High reliability in dirty service

The internal pressure channels are designed such that the medium inside is almost static, and particles or tar are not easily carried inside. This helps maintain accuracy over long periods even in dusty, tar-containing gas such as flue gas. -

Easy installation

Installation only requires drilling / hot tapping at the pipeline and inserting the probe to the centerline. The flowmeter can be welded or flanged in place. Pressurized (hot tap) installation is possible in many cases. -

Low maintenance

The primary measuring element (probe) itself typically does not require routine maintenance. Only periodic zero/span calibration of the differential pressure transmitter and verification of the analog signal to the secondary instrument are needed. -

Wide measurement range

- Gas flow ≥ ~6 m/s

-

Liquid flow ≥ ~0.5 m/s

This makes it suitable for both low flow and large pipe diameters. It can be used on gases, steam, and liquids, including tar, crude oil, heavy oil, and chemical solutions.

-

Flexible pipe geometry

Unlike many inline flowmeters that require round pipe and long straight runs, this technology can be applied to pipes with round, elliptical, square, rectangular, triangular, trapezoidal and other cross-sections. It also tolerates shorter straight-run conditions. -

Intelligent secondary instruments

The Pitoba Flow Meter can be paired with intelligent transmitters / integrators for local digital display and remote communication (to plant DCS / SCADA) to support centralized monitoring. -

Online serviceability

For measurement points that cannot be shut down, the probe can be installed, cleaned, or dredged online, even for media with high contamination.

5. Technical Specifications

Measuring Range Ratio

- Standard: 10:1

- Up to 20:1 in special cases

Pipe Size (DN)

- 20 mm ~ 8000 mm

Media

- Gas, steam, and liquid in full-pipe conditions

- Usable for fluids with viscosity ≤ 10 cP (special designs available for higher viscosity such as crude oil / tar)

Straight Pipe Requirement

-

Typical accuracy of 0.5% ~ 1.5% can be achieved with approx. 7D upstream and 3D downstream straight run

(D = pipe inner diameter)

Accuracy Classes

- ±0.5%

- ±1.0%

- ±1.5%

Repeatability

- ±0.05%

Operating Pressure

- 0 ~ 25 MPa standard

- Up to 32 MPa for special applications

Operating Temperature

- -100 °C to 650 °C standard

- Up to 800 °C (and higher with special high-temperature coatings such as Al₂O₃)

Measuring Upper Limit

- Determined by process flow rate and probe mechanical strength

Measuring Lower Limit

- Determined by the minimum measurable differential pressure

- Special low-ΔP designs are available for ultra-low flow measurement

6. Summary

The Pitoba Flow Meter is an ISO 3966–based averaging Pitot tube flowmeter with extremely wide applicability: gas, steam, or liquid; clean or dirty; low or high temperature; low or high pressure; small or extremely large pipe sizes.

It combines low pressure loss, simple installation, online serviceability, and intelligent compensation (pressure + temperature) to deliver stable and accurate flow measurement in demanding industrial environments.

English

English  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย  українська

українська  Malay

Malay  עברי

עברי  Indonesia

Indonesia  Ελλάδα

Ελλάδα  ಕನ್ನಡ

ಕನ್ನಡ  հայերեն

հայերեն

Email

Email

WA

WA

Inquiry

Inquiry