Related Products

Sodium hypochlorite is widely used as a chemical disinfectant in water treatment, chemical processing, food & beverage production, and other industrial applications. It plays a critical role in drinking water disinfection, wastewater sterilization, workshop sanitation, paper making, and bleaching processes.

In these industries, accurate chemical dosing and flow measurement directly determine treatment efficiency, safety compliance, and operating costs. Insufficient dosage may result in incomplete disinfection, excessive microbial content, and potential safety risks. Excessive dosage can cause chemical waste, increase operating costs, and even generate harmful by-products that raise the burden of downstream treatment.

Especially in high-hygiene applications, like municipal water systems or food processing, sodium hypochlorite concentrations must meet regulations. Selecting a suitable sodium hypochlorite flow meter is a key step in ensuring process compliance, stable operation, and long-term cost reduction in chemical dosing systems.

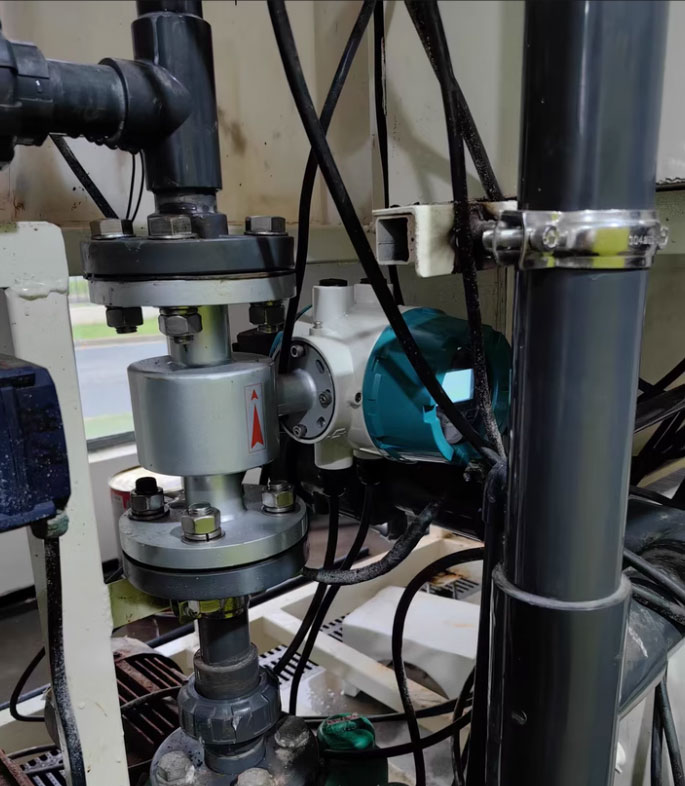

Sodium hypochlorite solution is inherently corrosive and may contain trace impurities under certain operating conditions. Traditional mechanical flow meters, for example turbine or vortex flow meters often suffer from corrosion, wear, or blockage, leading to unstable or inaccurate measurements.

A magnetic flow meter (electromagnetic flow meter), with no moving parts and excellent chemical compatibility, is an ideal chemical flow meter for sodium hypochlorite applications and other corrosive liquids. It can also be used as an acid flow meter and offers the following advantages:As a full-bore liquid flow meter, a magnetic flow meter is not affected by changes in density, viscosity, or temperature of sodium hypochlorite solutions. As long as the liquid has sufficient conductivity, the meter delivers stable and accurate readings, typically with an accuracy of ±0.2% to ±0.5%.

For sodium hypochlorite dosing systems with fluctuating concentrations, this high stability effectively minimizes measurement errors and ensures precise chemical injection control.The key to choosing a suitable sodium hypochlorite flow meter is to match the on-site operating conditions and the actual technical parameters of the electromagnetic flow meter. We usually asked for the following parameters before making a quotation:

Pipeline sizeThe sensor size should be selected based on the actual flow range. It's best to provide the minimum, commonly used, and maximum flow rates for the flow meter factory to choose from. The ideal solution is for the sensor size to match the size of the pipeline, and then the flow meter can fully cover the customer's hypochlorous acid flow rate.

If flow velocity is too high or too low, it is necessary to change the diameter of the on-site pipeline and the installation costs will increase accordingly. Magnetic flow meters generally require straight pipe lengths of 5D upstream and 3D downstream, and pressure loss should be considered if diameter changes are involved.

Due to the corrosive nature of sodium hypochlorite, material selection is critical. Here is the recommendation:

Electrodes: Titanium alloy or Hastelloy C for superior corrosion resistance

Lining: PTFE (Teflon) to isolate the sensor from chemical attack

Standard housing: carbon steel. For corrosive environments, SS304 or SS316 stainless steel housings can be selected to improve durability.For most industrial sodium hypochlorite applications, 0.5% or 1.0% accuracy is sufficient. This ensures reliable process control while maintaining a reasonable equipment cost, without unnecessarily pursuing ultra-high accuracy.

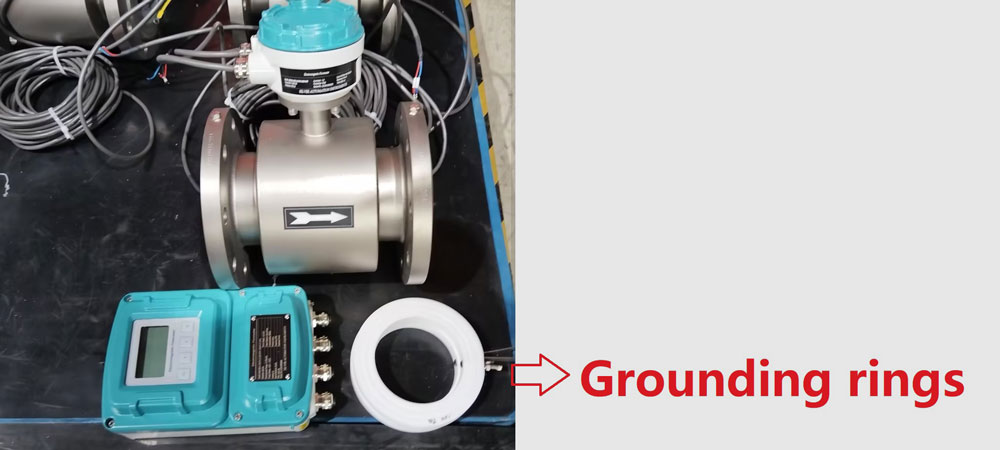

Sodium hypochlorite is corrosive, and pipelines are often plastic. Proper grounding is essential for stable electromagnetic flow measurement. Installing a grounding ring ensures signal stability. Since the grounding ring contacts the corrosive liquid, its material must also be corrosion resistant.

For corrosive chemicals such as sodium hypochlorite, accurate flow measurement is essential for efficient and compliant operation. Thanks to their corrosion resistance, high accuracy, wide adaptability, and low maintenance, electromagnetic flow meters are the preferred solution for chemical dosing and water treatment applications.

As long as the core parameters such as nominal diameter, material, and accuracy are accurately controlled in combination with the on-site working conditions, the electromagnetic flowmeter can fully play its role and provide strong guarantees for the stable and compliant operation of the production process.

we will contact you within 24 hours.