Nitrogen Pressure Transmitter: The Complete Guide to N2 Gas Pressure Measurement

Nitrogen pressure measurement is critical in industries ranging from semiconductor manufacturing to food packaging. Choosing the right nitrogen pressure transmitter ensures safety, efficiency, and regulatory compliance. This comprehensive guide covers everything you need to know about N2 pressure sensors, measurement challenges, and selecting the optimal solution for your application.

Why Nitrogen Pressure Measurement Is Critical in Industrial Applications

Nitrogen gas (N₂) serves as an essential inert gas across numerous industries including petrochemical, pharmaceutical, semiconductor, and food processing. Accurate pressure measurement for nitrogen gas is vital for:

- Safety compliance – Preventing overpressure conditions in storage tanks and pipelines

- Process optimization – Maintaining precise pressure control for quality production

- Cost reduction – Monitoring nitrogen consumption and detecting leaks early

- Equipment protection – Avoiding damage from pressure fluctuations

Understanding Nitrogen Gas Properties and Measurement Challenges

Physical Characteristics of Nitrogen Gas

Nitrogen is a colorless, odorless, and chemically inert gas with unique properties that affect pressure sensor selection:

- Density: 1.25 g/L at standard conditions (slightly lighter than air at 1.29 g/L)

- Chemical stability: Non-reactive with most materials, eliminating corrosion concerns

- Boiling point: -196°C (liquid nitrogen applications)

- Critical pressure: 3.39 MPa

Nitrogen is one of the most commonly used inert gases in industrial processes

Key Challenges in Nitrogen Pressure Monitoring

Wide pressure ranges: Industrial nitrogen pressure systems operate from low-pressure applications (few kPa) in laboratories to high-pressure storage (up to 40 MPa or 5,800 psi) in cylinders and bulk tanks.

Extreme temperature variations: From cryogenic liquid nitrogen at -196°C to high-temperature processes exceeding 300°C, requiring sensors with exceptional thermal stability.

Nitrogen storage tanks require reliable high-pressure transmitters for safe operation

Non-ideal gas behavior: At high pressures, nitrogen deviates from ideal gas laws, requiring pressure transmitters with advanced temperature compensation algorithms.

Purity requirements: Semiconductor and pharmaceutical applications demand ultra-high purity nitrogen (99.9999%), requiring sensors that prevent contamination through material outgassing.

Types of Nitrogen Pressure Sensors: Technologies Compared

Several pressure sensor technologies are used for nitrogen measurement:

1. Strain Gauge Pressure Transmitters

Pros: Cost-effective, widely available

Cons: Limited accuracy (±0.5%), poor long-term stability, sensitive to temperature drift

2. Capacitive Pressure Sensors

Pros: Good accuracy, relatively stable

Cons: Limited overpressure protection, affected by humidity and temperature

3. Piezoelectric Pressure Transducers

Pros: Fast response time, suitable for dynamic measurements

Cons: Cannot measure static pressure, expensive, complex signal conditioning

4. Resonant Silicon Pressure Transmitters (Advanced Technology)

Pros: Superior accuracy (±0.075%), excellent long-term stability, exceptional overpressure protection, wide temperature range

Cons: Higher initial cost (offset by lower total cost of ownership)

SH308-M Series: Professional Nitrogen Pressure Transmitter Solution

SH308-M Series: Industry-leading nitrogen pressure measurement solution

The SH308-M series pressure transmitter represents the latest advancement in nitrogen pressure monitoring, utilizing monocrystalline silicon resonant sensor technology and MEMS fabrication for unmatched performance.

Technical Specifications for Nitrogen Applications

| Specification | Performance | Benefit for N2 Measurement |

|---|---|---|

| Accuracy | ±0.075% of reading | Precise nitrogen flow control and quality assurance |

| Pressure Range | 1 kPa to 40 MPa | Covers all nitrogen applications from lab to industrial |

| Overpressure Protection | Up to 50 MPa | Prevents sensor damage during pressure spikes |

| Operating Temperature | -40°C to +85°C | Suitable for cold nitrogen and heated processes |

| Long-term Stability | ±0.2% URL/year | Reduces calibration frequency and maintenance costs |

| Response Time | 0.25 seconds | Fast dynamic pressure monitoring |

| Turndown Ratio | 100:1 | Single transmitter covers wide operating range |

1. World-Class Overpressure Protection for High-Pressure Nitrogen

The nitrogen pressure sensor features a robust monocrystalline silicon design with overpressure capability up to 50 MPa – far exceeding conventional diffused silicon or ceramic pressure sensors. This is critical for:

- High-pressure nitrogen cylinders (200-300 bar)

- Bulk nitrogen storage tanks

- Nitrogen compression systems

- Process equipment subject to pressure surges

Superior overpressure protection prevents costly sensor failures in nitrogen systems

Even for 40 MPa nitrogen systems, the transmitter maintains ±0.1%FS/MPa overpressure stability, ensuring measurement integrity during transient conditions.

2. Exceptional Temperature Performance for Nitrogen Gas Sensors

Temperature compensation is crucial for nitrogen pressure measurement because:

- Gas density changes with temperature affect pressure readings

- Sensor materials expand/contract with temperature

- Non-ideal gas behavior at extreme temperatures

The SH308-M delivers ±0.1%FS/10°C temperature effect, minimizing drift in applications with:

- Liquid nitrogen vaporization (-196°C to ambient)

- Heated nitrogen processes (up to 85°C)

- Outdoor installations with seasonal temperature swings

- Cryogenic storage facilities

3. Superior Long-Term Stability Reduces Maintenance Costs

Monocrystalline silicon technology ensures years of reliable nitrogen pressure monitoring

The monocrystalline silicon sensor exhibits minimal creep and hysteresis, achieving long-term stability of ±0.2% URL per year. For continuously operating nitrogen systems, this means:

- Extended calibration intervals – From quarterly to annual or longer

- Reduced maintenance costs – Less downtime and labor

- Improved process consistency – Stable measurements over years

- Better ROI – Lower total cost of ownership despite higher initial investment

Compared to traditional strain gauge sensors with drift rates 10x higher, the SH308-M pays for itself through reduced maintenance alone.

4. Flexible Configuration for Every Nitrogen Application

The N2 pressure transmitter offers comprehensive customization:

Pressure Types:

- Gauge pressure (for most nitrogen systems)

- Absolute pressure (for vacuum and low-pressure applications)

Process Connections:

- G1/2" (ISO 228)

- NPT 1/2" (ANSI/ASME)

- M20×1.5 (DIN)

- Custom flanged connections available

Multiple process connection options ensure compatibility with any nitrogen system

Diaphragm Materials:

- 316L Stainless Steel – Standard for most nitrogen applications

- Hastelloy C-276 – For nitrogen with trace corrosive impurities

- Gold-plated 316L – Ultra-high purity semiconductor applications (SEMI F20 compliant)

5. Advanced Digital Communication for Smart Nitrogen Monitoring

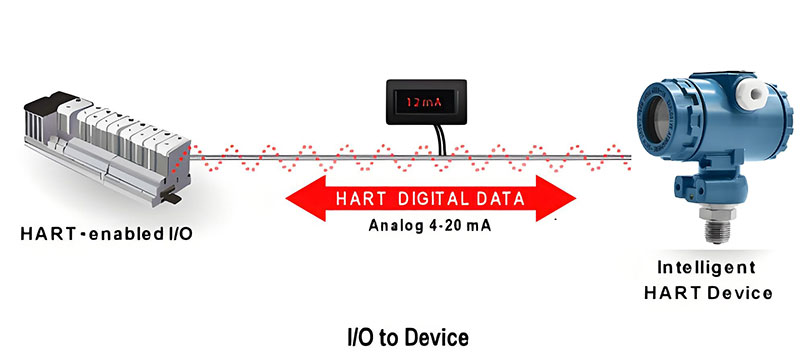

HART and MODBUS protocols enable smart nitrogen pressure monitoring and diagnostics

The SH308-M features comprehensive digital communication capabilities:

- Local Display: Backlit LCD for on-site pressure reading

- 4-20mA Analog Output: Universal compatibility with existing control systems

- HART Protocol: Digital communication over analog wires for diagnostics and configuration

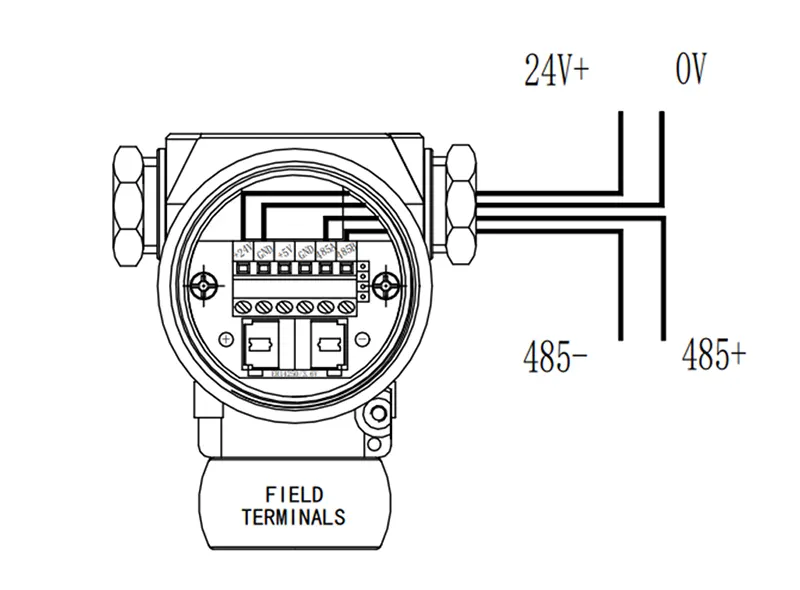

- MODBUS RTU (RS485): Integration with PLCs and SCADA systems

Download MODBUS Configuration Guide: RS485 Settings for Nitrogen Pressure Transmitters

RS485 MODBUS enables advanced nitrogen monitoring and data logging

Nitrogen Pressure Transmitter Applications: Industry-Specific Solutions

1. Air Separation and Nitrogen Generation Systems

In PSA (Pressure Swing Adsorption) and membrane nitrogen generators, the SH308-M excels at:

- Adsorption tower pressure monitoring (0-1 MPa typical range)

- Oxygen analyzer pressure correction (0.075% accuracy ensures precise O₂ measurement)

- Process optimization through real-time pressure profiling

- Energy efficiency by optimizing compression cycles

Accurate pressure measurement optimizes nitrogen generation efficiency

The 100:1 turndown ratio allows a single transmitter to cover pressures from startup to full load, while built-in temperature compensation ensures accuracy during daily thermal cycles.

2. High-Pressure Nitrogen Storage and Distribution

For nitrogen cylinder storage and bulk tank systems up to 40 MPa (5,800 psi), the SH308-M provides:

- Overpressure protection to 50 MPa – Critical safety margin

- IP67 weatherproof rating – Outdoor installation capability

- Remote monitoring via HART/MODBUS – Centralized pressure surveillance

- Hastelloy diaphragm option – Resists trace contaminants in industrial nitrogen

- Different pressure units – such as Kpa, mmH2O, bar,psig, Mpa,torr and so one.

3. Semiconductor Manufacturing: Ultra-High Purity Nitrogen

The semiconductor industry demands ultra-pure nitrogen (99.9999%+) for:

- Photolithography processes

- Dry etching chambers

- Chemical vapor deposition (CVD)

- Wafer cleaning and drying

The SH308-M's gold-plated 316L diaphragm fully complies with SEMI F20 standards for metallic ion contamination control. Combined with:

- 0.075% accuracy for precise gas flow control

- 0.25-second response time for critical process monitoring

- Three-button local calibration without contamination-prone cover removal

4. Cryogenic and Liquid Nitrogen Systems

Liquid nitrogen vaporization requires pressure transmitters with exceptional temperature range

While the SH308-M cannot directly measure -196°C liquid nitrogen, it performs excellently in:

- Vaporized nitrogen lines (-50°C to 0°C)

- Cryogenic storage tank vapor space

- Nitrogen backup systems

- Cold nitrogen purging applications

The fluorocarbon oil-filled version operates stably at -10°C, while standard silicone oil models handle -40°C.

5. Food and Beverage: Modified Atmosphere Packaging (MAP)

Nitrogen is widely used in food packaging to displace oxygen and extend shelf life. The SH308-M ensures:

- Consistent nitrogen flow for package quality

- Sanitary design with 316L stainless steel wetted parts

- Compliance with food safety standards

- Cost control through nitrogen consumption monitoring

6. Pharmaceutical and Biotechnology

Pharmaceutical manufacturing uses nitrogen for:

- Inert blanketing of reactors

- Tablet coating processes

- Lyophilization (freeze drying)

- Product packaging

The SH308-M meets FDA material requirements and supports GMP documentation through HART diagnostics and calibration records.

How to Select the Right Nitrogen Pressure Transmitter: Complete Guide

Step 1: Determine Pressure Range and Type

Rule of thumb: Select a maximum pressure range 1.5× your system's maximum working pressure (not exceeding 40 MPa for SH308-M).

Example: For a nitrogen system operating at 10 MPa, choose a 0-16 MPa range transmitter.

Available Nitrogen Pressure Ranges (SH308-M Series)

| Pressure Range | Type | Minimum Span | Maximum Span | Lower Limit | Overpressure |

|---|---|---|---|---|---|

| 0-1 kPa | Gauge | 0.1 kPa | 1 kPa | -1 kPa | 200 kPa |

| 0-6 kPa | Gauge | 0.6 kPa | 6 kPa | -6 kPa | 200 kPa |

| 0-40 kPa | Gauge | 4 kPa | 40 kPa | -40 kPa | 1 MPa |

| Absolute | 10 kPa | 40 kPa | 0 | 1 MPa | |

| 0-250 kPa | Gauge | 25 kPa | 250 kPa | -100 kPa | 4 MPa |

| Absolute | 10 kPa | 250 kPa | 0 | 4 MPa | |

| 0-3 MPa | Gauge | 150 kPa | 3 MPa | -100 kPa | 15 MPa |

| Absolute | 30 kPa | 3 MPa | 0 | 15 MPa | |

| 0-10 MPa | Gauge | 0.5 MPa | 10 MPa | -100 kPa | 20 MPa |

| 0-40 MPa | Gauge | 2 MPa | 40 MPa | -100 kPa | 50 MPa |

Step 2: Select Diaphragm Material

Material selection matrix for nitrogen applications:

| Application | Recommended Material | Reason |

|---|---|---|

| Standard industrial nitrogen | 316L Stainless Steel | Cost-effective, corrosion-resistant, suitable for most applications |

| Nitrogen with trace acids/chlorides | Hastelloy C-276 | Superior corrosion resistance to aggressive contaminants |

| Semiconductor ultra-high purity N2 | Gold-plated 316L | Eliminates metallic ion contamination, SEMI F20 compliant |

| Food & pharmaceutical | 316L Electropolished | Smooth surface prevents contamination, easy to clean |

Step 3: Choose Process Connection Type

Common process connection types for nitrogen pressure measurement

Connection selection guide:

- G1/2" (ISO 228): European and Asian standard, parallel threads

- NPT 1/2" (ANSI/ASME): North American standard, tapered threads

- M20×1.5 (DIN): Metric threading common in Europe

- Tri-clamp sanitary: Food, pharmaceutical, and biotech applications requiring frequent cleaning

- Flanged connections: Large diameter pipes or high-vibration applications

Step 4: Specify Communication Protocol

All SH308-M transmitters include 4-20mA analog output. Additional options:

- HART Protocol: Digital communication over existing 4-20mA wiring – ideal for retrofits

- MODBUS RTU (RS485): Direct digital connection to PLCs and SCADA – best for new installations

- Local display only: Budget option for applications requiring only visual indication

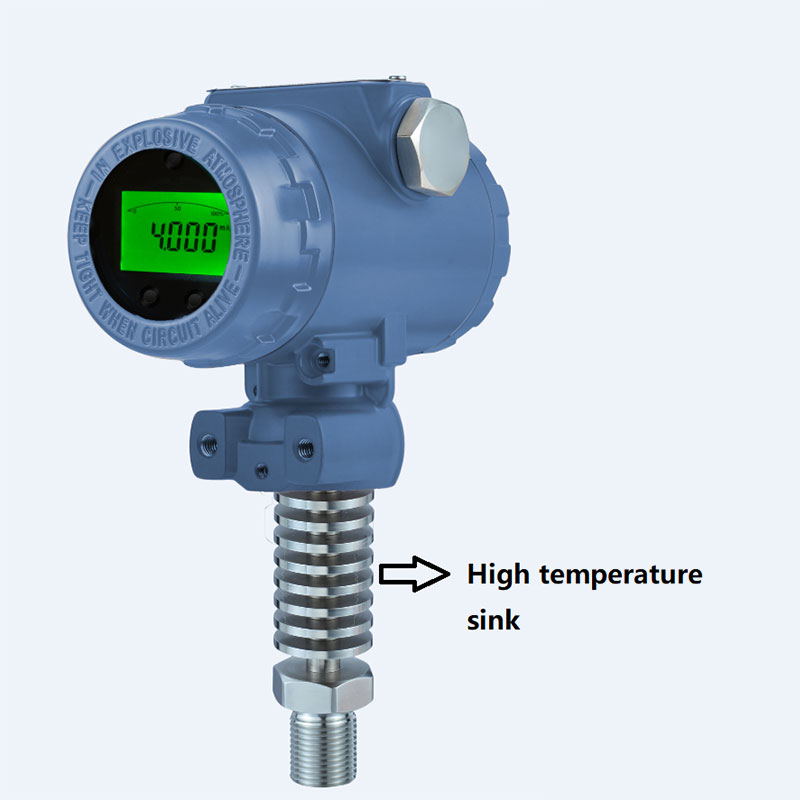

Step 5: Consider Special Options

For high-temperature nitrogen (>85°C):

- Heat sink R1 (up to 120°C)

- Heat sink R2 (up to 150°C)

- Heat sink R3 (up to 200°C)

Heat sink options extend operating temperature for hot nitrogen applications

For vibration environments:

- Adjustable damping time (0-99.9 seconds) to filter pressure fluctuations

- Rigid mounting brackets for secure installation

For hazardous areas:

- Intrinsically safe (IS) options available for explosive atmospheres

- ATEX and IECEx certifications (consult factory)

Installation Best Practices for Nitrogen Pressure Transmitters

Location Selection

DO:

- Install transmitters in accessible locations for maintenance

- Mount at or above the process connection to prevent liquid accumulation

- Provide adequate ambient ventilation if heat generation is a concern

- Install upstream of control valves to measure actual system pressure

DON'T:

- Install where liquid nitrogen can directly contact the sensor

- Place in areas with extreme vibration without proper damping

- Mount in direct sunlight or near heat sources

- Install in locations prone to mechanical damage

Mounting Recommendations

For high-pressure nitrogen systems (>10 MPa):

- Use U-bolt mounting on 50mm pipes for vibration resistance

- Install isolation valves for safe removal and maintenance

- Consider secondary containment for safety

For low-pressure systems (<1 MPa):

- Wall or panel mounting acceptable

- Ensure process connection is adequately supported

Electrical Installation

Critical wiring guidelines:

- Maintain minimum 15cm separation between signal and power cables

- Avoid parallel routing with high-voltage cables

- Use shielded cable for MODBUS RS485 connections

- Ground shield at one end only to prevent ground loops

- Follow local electrical codes and hazardous area requirements

Commissioning Checklist

- Verify pressure range matches system requirements

- Perform zero calibration with transmitter vented to atmosphere

- Check span calibration using known pressure reference (recommended)

- Configure output settings (4-20mA scaling, HART address, etc.)

- Set alarm limits if applicable

- Test communication with control system

- Document installation including serial number, range, and calibration data

Maintenance and Calibration of Nitrogen Pressure Sensors

Routine Maintenance Schedule

Daily:

- Visual inspection for physical damage or leaks

- Check local display reading (if equipped)

Monthly:

- Zero drift check (using three-button local calibration)

- Verify output signal at control system

Annually:

- Comprehensive performance verification using calibrated reference (≥3× accuracy)

- Document calibration results for quality records

- Inspect and clean process connection

Every 3-5 years:

- Fill fluid replacement (if applicable based on operating environment)

- Complete recalibration at factory or authorized service center

HART Communication for Advanced Diagnostics

HART protocol enables remote diagnostics and configuration

Using a HART handheld communicator or configuration software, technicians can:

- Remotely monitor sensor health including diagnostics flags

- Adjust damping time to optimize dynamic response without mechanical access

- Configure alarm currents (adjustable 3.6-22.8 mA)

- View critical parameters such as cumulative operating hours

- Perform remote calibration using known pressure references

- Update device configuration without interrupting 4-20mA signal

Troubleshooting Common Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Zero drift over time | Temperature cycling, sensor aging | Perform zero calibration using three-button local procedure |

| Noisy or fluctuating signal | Turbulent flow, vibration, electrical interference | Increase damping time, check cable shielding, isolate from vibration |

| No output signal | Power supply failure, wiring issue, sensor failure | Check power supply voltage, verify wiring continuity, test current loop |

| Inaccurate reading | Span error, temperature effect, process condition change | Perform span calibration, verify temperature compensation, check for non-ideal gas behavior |

| Cannot communicate via HART/MODBUS | Incorrect addressing, cable issue, termination resistor missing | Verify device address, check cable connections, install termination resistors |

Total Cost of Ownership: Why SH308-M Delivers Superior Value

While the SH308-M nitrogen pressure transmitter has a higher initial cost than basic sensors, its total cost of ownership (TCO) is significantly lower:

TCO Analysis (5-Year Period)

| Cost Factor | Basic Strain Gauge | SH308-M Series |

|---|---|---|

| Initial purchase | $300 | $800 |

| Calibration (4× quarterly vs 1× yearly) | $2,000 | $500 |

| Replacement due to failure (2 units vs 0) | $600 | $0 |

| Process downtime costs | $3,000 | $500 |

| Total 5-Year TCO | $5,900 | $1,800 |

Result: The SH308-M delivers 69% lower TCO and superior measurement performance.

Nitrogen Pressure Measurement FAQs

What pressure range do I need for nitrogen cylinders?

Standard nitrogen cylinders operate at approximately 15-20 MPa (2,200-2,900 psi) when full. We recommend a 0-25 MPa or 0-40 MPa range transmitter with 50 MPa overpressure protection for safety.

Can the same transmitter measure both liquid and gaseous nitrogen?

The SH308-M cannot directly contact liquid nitrogen at -196°C. For cryogenic applications, install the transmitter on the vapor phase above liquid nitrogen or on vaporized nitrogen lines where temperature exceeds -40°C.

How often should I calibrate my nitrogen pressure transmitter?

The SH308-M's exceptional stability allows annual calibration intervals for most applications. Critical processes may require semi-annual verification. Always follow your quality management system requirements (ISO, GMP, etc.).

What's the difference between gauge and absolute pressure measurement?

Gauge pressure measures relative to atmospheric pressure (most common for nitrogen systems). Absolute pressure measures relative to perfect vacuum (required for vacuum applications and when barometric pressure variation affects the process).

Can I use this transmitter in explosive atmospheres?

Intrinsically safe and explosion-proof versions are available. Consult factory for specific ATEX, IECEx, or FM certifications matching your hazardous area classification.

What causes nitrogen pressure transmitter failure?

Common failure modes include: overpressure damage (prevented by SH308-M's 50 MPa protection), moisture ingress (IP67 rating prevents this), electrical surge damage (protected by internal circuit design), and mechanical shock. Proper installation and selection prevent most failures.

Industry Standards and Compliance

The SH308-M nitrogen pressure transmitter complies with:

- Accuracy standards: IEC 60770 (transmitters), ASME B40.100 (pressure instruments)

- Electrical safety: IEC 61010-1, UL 61010-1

- EMC compliance: IEC 61326-1 (industrial environments)

- Materials: NACE MR0175/ISO 15156 (sour service), FDA CFR 21.177 (food contact)

- Semiconductor: SEMI F20 (metallic contamination control)

- Quality: ISO 9001 manufacturing

Conclusion: Selecting the Right Nitrogen Pressure Measurement Solution

Accurate nitrogen pressure measurement is critical across industries from semiconductor fabrication to food packaging. The SH308-M series nitrogen pressure transmitter represents the optimal solution, combining:

- ✓ Industry-leading accuracy (±0.075%) for precise process control

- ✓ Exceptional overpressure protection (50 MPa) for safety and reliability

- ✓ Wide operating temperature range (-40°C to +85°C) for diverse applications

- ✓ Superior long-term stability (±0.2%/year) reducing maintenance costs

- ✓ Flexible configuration options for any nitrogen system requirement

- ✓ Advanced digital communication enabling smart monitoring and diagnostics

Whether you're monitoring high-pressure nitrogen cylinders, optimizing nitrogen generation systems, ensuring semiconductor-grade purity, or managing cryogenic liquid nitrogen facilities, the SH308-M delivers reliable, accurate pressure measurement with the lowest total cost of ownership.

Ready to upgrade your nitrogen pressure monitoring? Contact Silver Instruments today for application-specific recommendations, technical support, and competitive pricing. Our engineering team will help you select the optimal configuration for your nitrogen system requirements.

Explore SH308-M Nitrogen Pressure Transmitter Specifications »

Keywords: nitrogen pressure transmitter, N2 pressure sensor, gas pressure measurement, pressure transmitter for nitrogen, nitrogen gas monitoring, high pressure nitrogen sensor, industrial pressure transmitter, nitrogen cylinder pressure gauge, pressure sensor selection, nitrogen system monitoring

English

English  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย  українська

українська  Malay

Malay  עברי

עברי  Indonesia

Indonesia  Ελλάδα

Ελλάδα  ಕನ್ನಡ

ಕನ್ನಡ  հայերեն

հայերեն

Email

Email

WA

WA

Inquiry

Inquiry