Introduction

Rotameters (or we call variable area flow meters/VA flow meters) paired with needle valves are a classic and reliable solution for precise flow measurement and regulation across a lot of industries. This simple but classic combination is widely used in gas and liquid flow and control applications where accuracy, simplicity, and low price cost are essential. This article explores the working principles of rotmaters flow meters, advantages, selection methods, and applications of rotameter-needle valve systems. silverinstruments.com provide classical combination of rotameter and need valve with low price and reliable flow measurement solutions.

How Rotameters and Needle Valves Work Together

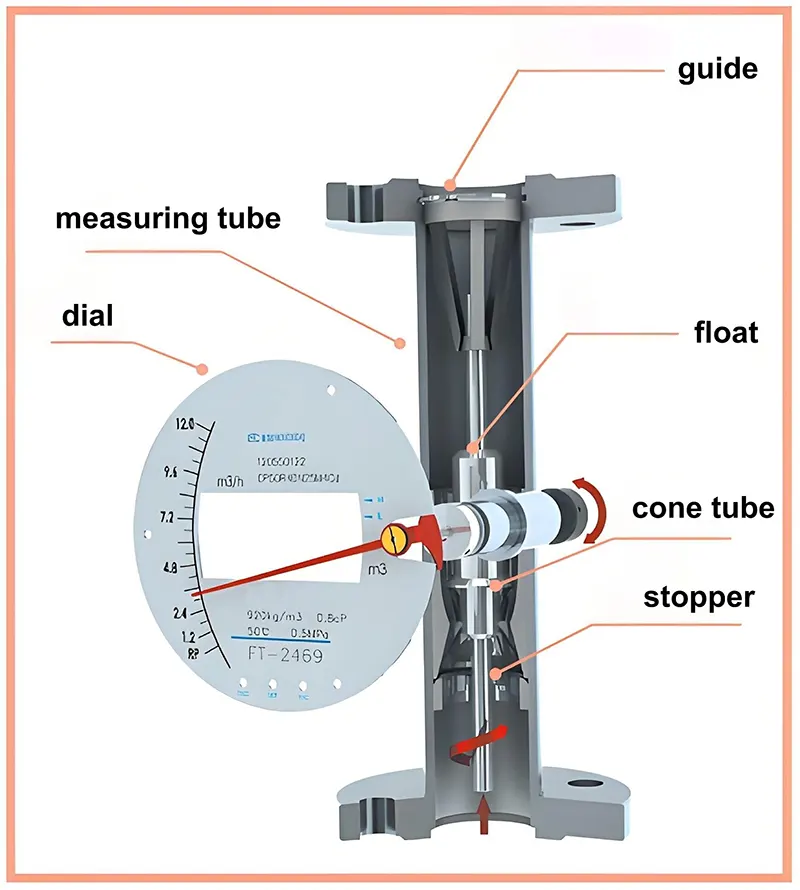

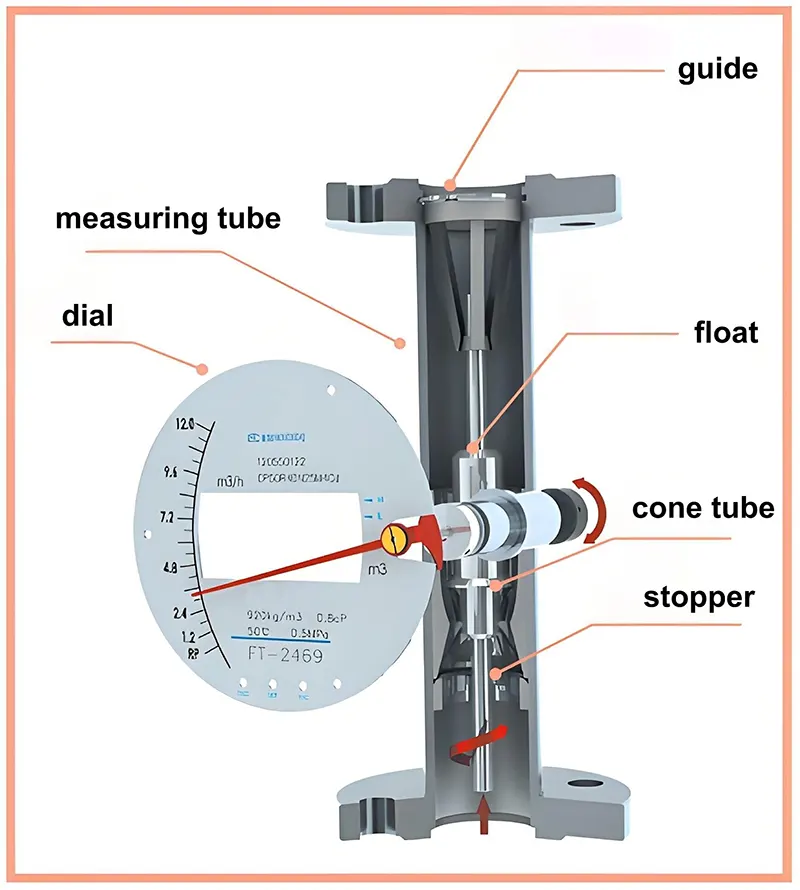

1. Rotameter Functionality

A rotameter operates on the principle of variable area flow measurement (VA flow meter), where a float (or piston) rises or falls inside a tapered tube in response to fluid flow. The position of the float indicates the fluids flow rate, which is read against a calibrated scale.

Key features:

- No external power required – Operates based on mechanical balance between buoyancy, drag, and gravity. However silverinstruments.com also has option of

rotameters with transmitters.

- Linear scale – Easy to read, typically calibrated for specific fluids (air, water, etc.). so when you ordering rotameters from silverinstruments.com you need to specify fluids type and density informaiton to us.

- Wide flow range – Can measure from small flow a few mL/min to thousands of LPM (liters per minute), we have many sensor sizes available ,from 1/2" rotameters to 8 inches rotameters.

2. Role of the Needle Valve

A needle valve complements the variable area flow meter by providing fine flow control. Its tapered pin allows for gradual adjustment, making it ideal for

low-flow measurement applications.

Needle valve equipped together with rotameter

Rotameter with need valve functions:

- Accurate flow regulation – Enables fine-tuning to match desired flow rates which you want.

- Flow stabilization – Reduces turbulence and pulsation on the measured fluids, ensuring accurate and reliable readings.

- System protection – Prevents sudden surges that could destroy the rotameter.

Advantages of Using Rotameters with Needle Valves

✓ Simple flow meter Installation: No complex electronics or programming required.

✓ Flow meter needs low Maintenance: No moving parts (except the float), reducing wear.

✓ Low cost flow meter: More affordable than

digital mass flow controllers.

✓ Visual Confirmation: Direct reading without additional other flow totalizers.

✓ Versatility: Works with gases ,steam and liquids, depending on your ordered fluids type,total customized flow meters.

Rotameter with needle valve is more affordable than digital mass flow controller

Key Selection methods

1. Flow Sensor material Compatibility

- Wetted parts: Choose float flow meter stainless steel 304, 316 or 316L ,or PTFE lined for corrosive fluids.

- Seals: Viton, EPDM, or PTFE for chemical resistance.

2. Flow Range & Accuracy

- Ensure the rotameter covers the required range (e.g., 0-300 LPM for air), consult silverinstruments.com to size your flow rate.

Below is the flow range table for

HH50 series rotameters from silverinstruments.com

|

Water (L/h)

|

Air (m3/h)

|

HH50 Max Pressure los

|

|

Diameter

|

Float No.

|

Material

R0,R1,Ti,RL

|

Material

PTFE

|

@0.1013MPa 20°C

|

Water

(Kpa)

|

Air

(Kpa)

|

|

15

|

H15.1

H15.2

H15.3

H15.4

H15.5

H15.6

H15.7

H15.8

H15.9

|

1.6~16

2.5~25

4.0~40

6.3~63

10~100

16~160

25~250

40~400

63~630

|

1.6~16

2.5~25

4.0~40

6.3~63

10~100

16~160

25~250

40~400

|

0.05~0.5

0.07~0.7

0.11~1.1

0.18~1.8

0.28~2.8

0.48~4.8

0.7~7

1.0~10

1.6~16

|

2.0

2.3

2.5

2.5

2.5

2.6

2.7

2.9

3.4

|

7.0

7.2

7.3

7.5

7.8

8.0

10.0

10.8

14

|

|

25

|

H25.1

H25.2

H25.3

H25.4

H25.5

H25.6

|

63~630

100~1000

160~1600

250~2500

400~4000

630~6300

|

40~400

63~630

100~1000

160~1600

250~2500

400~4000

|

1.6~16

3.0~30

4.5~45

7.0~70

11~110

18~180

|

4.0

4.1

4.4

5.2

7.0

12.5

|

7.0

8.0

12.0

19.0

25.0

33.0

|

|

50

|

H50.1

H50.2

H50.3

H50.4

|

630~6300

1000~10000

1600~16000

2500~25000

|

400~4000

630~6300

1000~10000

1600~16000

|

18~180

25~250

40~400

100~1000

|

4.7

5.1

6.2

8.0

|

8.0

15.0

22.0

35.0

|

|

80

|

H80.1

H80.2

|

2500~25000

4000~40000

|

1600~16000

2500~25000

|

100~1000

120~1200

|

5.3

7.8

|

15.0

22.0

|

|

100

|

H105.1

H105.2

|

6300~63000

10000~100000

|

4000~40000

6300~63000

|

180~1800

300~3000

|

11.4

16.7

|

35.0

|

|

150

|

H155.1

|

15000~150000

|

10000~100000

|

400~4000

|

17.0

|

|

- Standard accuracy: ±2% to ±5% FS (higher precision available with calibration).

3. Pressure & Temperature Limits

- Most glass rotameters handle <10 bar; needle valves should match system pressure.

- Temperature limits depend on materials (e.g., glass tubes may break under thermal shock). Metal tube rotameters can bear higher temperature and higher pressure

Metal tube rotameters can bear higher pressure and higher temperature

4. Needle Valve Integration

- Direct-mounted valves (built into the rotameter) simplify installation.

- Separate valves allow flexibility in piping layout.

Common Industrial Applications

1. Gas Flow Control

- Laboratory gas distribution (N₂, O₂, CO₂,H

2).

- Process industries (air flow meter,

natural gas flow meter, specialty gases).

2. Liquid Dosing & Metering

- Chemical injection (pH control, water treatment).

- Food & beverage (

syrup flow meter, sanitizer dispensing).

3. HVAC & Compressed Air Systems

-

Airflow monitoring in pneumatic systems.

- Leak testing with adjustable flow rates.

4.Medical & Pharmaceutical

- Oxygen therapy devices.

- Bioreactor gas supply control.

Limitations & Alternatives

1. When Rotameters May Not Be Suitable

- High-pressure systems

- Extremely low flows,such as 2 sccm low flow measurement, (better suited for

mass flow controllers,that is MFC ).

- Non-transparent fluids (obscure float visibility).

Mass flow controller can handle 2 ml/min low flow while rotameters can not

2. Alternative Solutions

- Digital flow meters (thermal mass flow controllers,

Coriolis mass flow controllers) for higher precision.

- Mass flow controllers (MFCs) for automated regulation.

Coriolis mass flow controller

Conclusion

Rotameters with needle valves remain a simple, reliable, and cheap solution for flow measurement and control. Their mechanical operation, ease of use, and adaptability make them ideal for industries ranging from chemical processing to aquaculture.

For optimal performance:

✔ Match the rotameter to the fluid and flow range,opertation temperature and pressure.

✔ Use a high-quality needle valve for precise adjustment.

✔ Consider flow sensor material compatibility for long-term durability.

By understanding their working principles and applications, engineers can effectively deploy rotameter-needle valve systems for efficient flow management.

Welcome contact

silverinstruments.com for more information if you want to buy rotameters with needle valve.