What is a Metal tube variable area flow meter?

Variable area flow meter or called Rotameter is one of the most commonly used throttling flowmeters. Variable area flow meter has the advantages of simple construction of flow sensor, robust measurement, wide detection measurement range (the range ratio can reach 10:1), high measurement accuracy (error about ±1.5%), and indication value. It is the most widely used measuring flow instrument in modern life and industrial production due to its advantages of intuition, convenient maintenance , small pressure loss, high accuracy and low price cost.

Why choose metal tube variable area flow meter?

In which situation to choose metal tube variable area flow meter instead of glass or plastic tube?

According to the different materials of the tapered tube of variable area flow meter, it can be roughly divided into three categories: Glass tube, plastic tube and metal tube variable area flow meter. Glass tube rotor flowmeter is simple in structure, very cheap cost, easy to be made into an flow sensor for corrosive liquid or gas, has high transparency, intuitive reading, not easy to break, light weight, long life, convenient installation and connection, etc. The plastic tube rotameter has the characteristics of small size, light weight, unbreakable tapered tube and corrosion resistance flow meter.

Metal tube rotameter can measure liquid and gas flow, especially suitable for liquid or gas flow measurement with low flow rate and small flow. It can provide flow rate, total flow display, or 4-20mA output signal to realize flow indication, accumulation, signal transmitting, flow recording, control and alarm, etc. Function.

Today, with the continuous development of measurement technology and the increasing demand for measurement accuracy, metal tube variable area flow meter factory can only fully understand the structural principle of the rotameter, flow calculation, factors affecting the value and correction methods, and the selection and installation requirements of the flowmeter. Choose the correct Metal tube variable area flow meter that best meets your needs to achieve the best measurement results. The author hopes that this paper will bring some help to metrology workers.

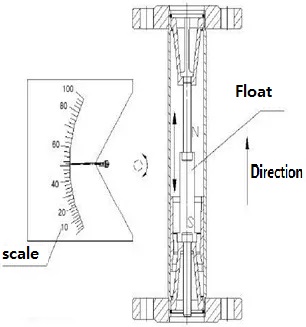

Metal tube variable area flow meter construction

Metal tube variable area flow meter is composed of two parts, one is a tapered tube that gradually expands from bottom to top, and the other is a rotor tapered tube placed in the tapered tube, which can move up and down along the center line of the metal tube and is slightly denser than the fluid. The rotor position in the metal tapered tube is transmitted outside the tube through magnetic coupling, etc., and the value is displayed on the panel and indicated by a pointer. It can be made into digital Metal tube variable area flow meter with transmitters to have total value indication and transmitting the flow signals.

How metal tube variable area flow meter works?

When measuring the flow rate of the fluid, the fluid flows into the impact rotor from the lower end of the conical metal tube, and generates a force on it, and the magnitude of the force changes with the flow rate; when the flow rate is large enough, the generated force lifts the rotor up and makes it rise; the fluid flows out from the upper end through the annular section between the rotor and the conical metal tube wall. When the force of the fluid on the rotor is equal to the weight of the rotor, the rotor stays at a certain position due to the force balance; this position has a corresponding relationship with the flow rate, and the flow value can be obtained according to this position.

The flowmeter rotor is subjected to three forces in the conical metal tube: gravity, dynamic pressure and buoyancy. When the three forces are balanced, the rotor gravity = dynamic pressure + buoyancy. When the flow rate becomes larger or smaller, the rotor will move up or down, and the cross-sectional area of the fluid flow will also change, until it reaches the corresponding flow rate at equilibrium, and the rotor is stable in the new position in the metal tube. The floating height of the rotor corresponds to the flow rate; according to the difference in height can be used to mark the flow value, and the flow value can be read immediately in practical applications.

Due to the diversity of fluids and the complexity of the environment, there are many difficulties in the correction of the discharge coefficient. If very accurate measurement is required, the user can ask the metal tube flow meter manufacturer to calibrate the flow meter scale with the actual fluid, so that the real value in the working environment can be directly obtained without various corrections. Silver Automation Instruments manufacture variable area flow meter analog or with transmitter type.

Metal tube variable area flow meter applications

If the fluid is medium and small flow, easy to vaporize (or easy to condense), toxic, flammable and explosive, free of magnetic substances, fibers and abrasive substances, and non-corrosive to stainless steel, an ordinary metal tube rotameter can be selected; if the fluid is corrosive or is easy to crystallize or vaporize or has high viscosity, a metal tube rotameter with jacket and heat tracing or cooling jacket should be used.

In high temperature or high cold, high pressure, toxic environment, the Metal tube variable area flow meter with remote transmitter should be selected. In a word, metal tube variable area flow meter can be made into high pressure or high temperature flow meter, max pressure can reach to 6100 PSI, max fluids temperature can be 300°C.

If the fluid pressure is unstable, especially when it is used for gas measurement, a rotameter with a damping should be selected.

Features of Metal tube variable area flow meter

-

Rugged all-metal construction including measuring tube, robust float flow meter

-

Choose from a variety of materials, such as SUS304, 316, stainless steel 316L or PTFE lined material

-

Insulation jacket type design options

-

High temperature floats flow meter option

-

With air damping device for gas or air measurement;

-

low pressure loss for float flow meter;

-

VA flow meter is suitable for harsh environments, corrosive acids.

-

Metal tube variable area flow meter has good shock resistance, heat resistance

Metal tube variable area flow meter Specifications

-

Metal tube variable area flow meter size: 1/2”, 1 inch, 2inch, 50mm dial size, 3 inch, DN100, DN200, 6 INCH,8” ,10 inch Metal tube variable area flow meter.

-

Working power: 24VDC, 220V AC or battery operated Metal tube variable area flow meter;

-

Output signal: two-wire system 4~20mADC;

-

Input impedance: >100MΩ; standard load resistance: 250Ω

-

Flange standard: JIS, ANSI B16.5,DIN;

-

Operation pressure: 1.6 MPa; 2.5 MPa; 4.0 MPa; 6.3 MPa, 150 PSI, 300 PSI, 600# , 900 pounds

-

Turndown ratio: 10:1

-

Accuracy: 1.5%FS or 1.0%

-

Fluids temperature: -50~300°C

-

Measuring range: Water: 25-100000 L/h (20°C) Air: 0.7-1800m³/h (0.1013MPa, 20°C),100-100LPH,6300-63000LPH, 42-420LPM,1-10 m3/h,80-800 m3/h,264-2640 GPM.,etc.

Installation of Metal tube variable area flow meter

Correct installation is a necessary condition for the metal tube flowmeter to work properly and measure accurately. Generally, the following requirements should be followed:

(1) Metal tube variable area flow meter normally is installed vertically, the fluid flows through the flowmeter from bottom to top, and the verticality is better than 2°, however horizontal mounting variable area flow meter is also available for Silver Automation Instruments.

(2) The inlet should have a straight pipe section that is more than 5 times the diameter of the pipe, and the flow meter is normal 250mm length.

(3) Appropriately install pipe supports at the installation location.

(4) A bypass pipeline and bypass valve should be installed beside the flowmeter, and a check valve should be installed downstream.

(5) If the measuring fluid is a dirty medium or contains solid impurities, a filter and a regular cleaning device must be installed at the inlet.

(6) If the measurement fluid contains ferromagnetic substances, a magnetic filter should be installed before VA flow meter.

(7) The rotor flowmeter powered by liquid crystal or lithium battery should avoid direct sunlight and high temperature environment (≥65℃).

(8) The working pressure of the measuring gas should not be less than 5 times the pressure loss of the flowmeter.

The float rotameter has a simple structure and an uncomplicated principle. However, due to the correlation between the flow measurement characteristics and the fluid properties, as well as the vast differences in the physical properties of the fluid, the application of flow measurement technology becomes very complicated. Not only the difference in viscosity of fluids, but also the compressibility and thermal expansion of gaseous fluids make fluid measurement more difficult. Please contact SILVER AUOTMATION INSTRUMENTS to tell all metal tube flow meter applications information, they will choose the correct type and low cost type Metal tube variable area flow meter for you. ABB,Brooks metal tube variable area flow meter is good instruments, but SILVER flow meters are economical replacement.