How bidirectional flowmeter works?

Electromagnetic flowmeter is a commonly used bidirectional flowmeter which is capable of measuring liquid in both forward and reverse direction. When the conductive liquid moves across the magnetic field, a voltage proportional to the speed is generated in the conductive flow.

The bidirectional liquid flow measured by electromagnetic flow meter has the following features:

☑ As long as the fluid has some conductivity, the volume flow can be measured without being affected by conditions such as liquid temperature, pressure, density, viscosity, etc.

The output voltage is proportional to the liquid volumetric flow, and the measurement range is wide.

☑ Bi-directional flow meters have no pressure loss.

☑ The bidirectional flowmeter sensor detection unit has no moving parts.

☑ The flow rate of the fluid in forward and reverse directions can be measured.

☑ The bidirectional flowmeter transmitter responds quickly.

☑ When using the bidirectional flowmeter to measure the volume flow, there is no obstacle in the flow of the fluid, so as long as the material of the detection part is selected, it can measure mud or highly

corrosive liquid flow meter, such as acid flow. Due to these characteristics, electromagnetic flowmeters occupy an important position in the process industry, and

☑ there are many applications for bidirectional flow measurement of liquids.

☑ Because the fluid must be electrically conductive,

electromagnetic flowmeters cannot measure gases and oils. Although there are experiments using electromagnetic flowmeters to measure oils, they have not been practically applied. But at present we have other ways to measure the bidirectional flow of the medium, such as bidirectional flow ultrasound, positive displacement flowmeter and so on.

Fluids can be measured by Bidirectional flow meter

Bidirectional flow meter can measure conductive liquid such as drinking water, well water, fire fighting water, fruit juice, sewage, sea water, mineral water, hydrochloric acid, sulfuric acid, nitric acid, pulp, brine, etc.

Bidirectional flow meter Technical Specifications

☑ The bidirectional flowmeter in contact with the medium has electrodes and lining materials, and the common electrode material is SUS 316. When used to measure corrosive fluids, the electrode materials are mostly platinum-iridium alloy, Hastelloy alloy B, Hastelloy alloy C, titanium, and Monel alloy. Lining materials usually use neoprene, polyurethane, tetrafluoro,TEFLON,PFA and so on.

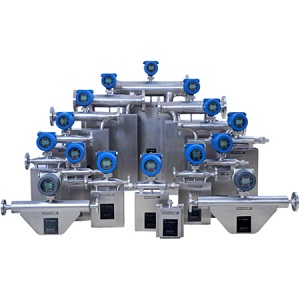

☑ The mechanical hardware components of electromagnetic flowmeters are roughly divided into flow sensor that are in contact with the fluid to be measured and converters that amplify and transform electrical signals. These structures and working principles vary with the method of the magnetic field applied to the fluid, so according to the different excitation methods, it can be divided into DC or AC magnetic fields in practical applications.

☑ Now, the diameter of the detector used in industry is 2 to 3000 mm, and the maximum value of the two-way flow velocity is generally taken as 0.3 to 10 m/s. The lower limit of flow is determined by the S/N ratio of the same noise or offset. The upper limit is determined by the wear of the pipe lining and the economical speed of the piping. Commonly used bidirectional flowmeters are 1/2”, 3/4 inch, 1”, 2 inch, DN50, 3 INCH, 80mm, DN100, 150mm,

6 inch flow meter, 8 inch, 10 inch, 12 inch, 14 inch, 16” ,18”,20 inch etc.;

☑ When the full scale is above 1 m/s, the combined accuracy of the detector and the converter is ±0.5%, and when the full scale is 0.3-1 m/s, it is ±1.0-1.5%.

☑ The fluid temperature range is usually determined by the material of the lining. The commonly used temperature range is 0-160°C. The temperature of the medium measured by the rubber lining cannot exceed 60°C. When measuring the bidirectional flow of hot water, the PTFE lining material can be selected.

☑ The pressure range is -1 to 160 kgf/cm2. In order to increase the pressure resistance of the detector, it is necessary to increase the wall thickness of the pipeline and increase the pressure rating of the flange. Pay attention to whether the lining material can withstand high pressure.

☑ Electronic bidirectiona flowmeter, with electronic display, showing liquid positive and negative volume flow, cumulative total flow; with current 4-20Ma analog ouput and pulse output, frequency output, can have MODBUS RTU communication, HART communication, or PROFIBUS-DP.