Related Products

Air turbine flow meter overviewTurbine air flowmeter is almost independentof air density, pressure, temperature and other parameters when measuring thevolumetri...

Understanding Insertion Mass Flow Meter: An Efficient Gas Flow Measurement SolutionAn insertion mass flow meter, also known as an insertion thermal gas flow met...

When installing a flow meter in a compressed air system, many people's first reaction is to cut a section of the pipeline and install an in-line one with flange connection or screw connection. But in recent years, more and more factories have started using insertion flow meters, especially for measuring compressed air. Why is this?

customers prefer use insertion flow meter for compressed air because easy installation

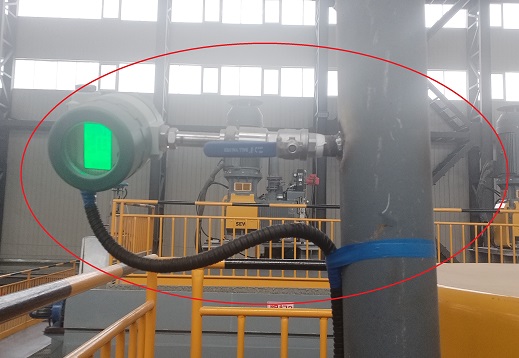

A characteristic of compressed air systems is that the pipelines are often already laid and production cannot be stopped. If the pipeline is cut and re welded just to install a compressed air flow sensor at this time, the losses from production stoppage will be much more expensive than the flow meter. The biggest advantage of insertable flow meters is that they can be installed online - by drilling a hole in the pipeline and inserting the probe, the screw can be tightened and used without affecting production. Especially suitable for renovation projects, or for sites with old pipelines that dare not make major changes.Insertion thermal mass flow meter

Thermal mass flow meter calculates flow rate by heating and measuring temperature with a probe. Its advantage is its wide range, which can accurately measure from light to strong winds, and the probe is not afraid of vibration, making it suitable for situations where the airflow at the outlet of the air compression station is unstable. The disadvantage is that it is sensitive to dust and oil stains, and if the back of the air compressor is not properly treated, the probe is prone to getting dirty. Good news is that insertion thermal mass flow meter and in-line thermal mass flow meter has the same accuracy.

The flow rate is calculated based on the vortex frequency behind the probe. It is sturdy and resistant to dirt, with some oil stains and water vapor not affecting it much. Its price is usually one level lower than that of traditional heat pumps. But they are afraid of vibration. If the air compressor vibrates greatly or the pipeline vibrates severely, the measurement may show a jump. The range is also narrower than that of the heat type, and it can measure well in strong winds, but it may "mute" in small winds. But insertion vortex type flow meter has poorer accuracy than in-line type vortex flow meter .

While for insertion thermal mass flow meter , the cost starts from $900 .

In general, in the compressed air scenario, unless it is a brand new pipeline or a cost-effective project, insertion compressed air flow meters are often a more practical choice. It is like a stethoscope for a "pipe doctor", which can diagnose system problems without surgery. For most factories, it is sufficient, easy to use, and worry free.we will contact you within 24 hours.