Natural gas is a high-quality energy and chemical raw material that requires precise metering. The main component of natural gas is methane, and gas turbine flowmeters are excellent instruments for natural gas metering. These meters are suitable for measuring non-corrosive gases such as natural gas, propane, fuel gas, and feed gas.

The turbine meter measures volumetric flow based on gas flowing past a free-spinning rotor, with each revolution corresponding to a specific volume of gas or air.

Why We Need Temperature and Pressure Correction

When the gas turbine flowmeter is measured in a pipeline, the density of natural gas varies with temperature and pressure. For accurate measurement, it's necessary to simultaneously track the temperature and pressure of natural gas, and convert the volume flow under different working conditions into a standard state or an agreed state volume flow.

The gas turbine flowmeter can integrate temperature, pressure, and flow sensors to track and detect natural gas temperature and pressure and perform automatic compensation and compression factor correction calculations. Therefore, it has excellent performance in both low-pressure and high-pressure metering applications.

Features

- High Precision – Good repeatability, low pressure loss, good seismic performance

- In-line Volume Flow Meter – Direct pipeline installation

- High-Quality Bearings – Low frictional resistance and good sealing

- Multiple Output Options – Pulse signal and analog signal output, with MODBUS communication interface available (Modbus option)

- Low Power Consumption – Can be powered by internal battery or external power supply

- Data Protection – Real-time data storage prevents loss during battery replacement or power outage

- Explosion-Proof Design – Suitable for hazardous environments

- Cost-Effective – Low price gas flow meter with excellent performance

Technical Parameters

- Medium: Clean, no impurities, medium and low flow rate natural gas

- Flow Sensor Range: 20mm (3/4 inch) ~ 400mm (16 inch)

- Temperature/Pressure Correction: Optional compensation function available

- Process Connection: Threaded or flanged

- Accuracy: ±1.5%R, ±1.0%R

- Range Ratio: 1:10~1:30

- Power Supply: Built-in lithium battery 3.6VDC, external 24VDC

- Temperature Range: -20~60 °C

- Materials: Housing: 304 stainless steel, impeller: anti-corrosion ABS or aluminum alloy

Flow Range Specifications

| Size (mm) | Standard (m³/h) | Extended (m³/h) | Standard Pressure | Special Pressure | ||

|---|---|---|---|---|---|---|

| DN20 | S | 2-20 | W | 4-40 | 1.6Mpa | Thread ≤4.0Mpa, Flange ≤6.3Mpa |

| DN25 | S | 2.5-25 | W | 4-40 | Thread ≤4.0Mpa, Flange ≤6.3Mpa | |

| DN32 | S | 4-40 | W | 6-60 | Thread ≤4.0Mpa, Flange ≤6.3Mpa | |

| DN40 | S | 5-50 | W | 6-60 | Thread ≤4.0Mpa, Flange ≤6.3Mpa | |

| DN50 | S1 | 6-65 | W1 | 5-70 | Thread ≤4.0Mpa, Flange ≤6.3Mpa | |

| S2 | 10-100 | W2 | 8-100 | 1.6Mpa | ||

| DN65 | S | 15-200 | W | 10-200 | 1.6Mpa | Flange ≤6.3Mpa |

| DN80 | S1 | 13-250 | W | 10-160 | 1.6Mpa | Flange ≤6.3Mpa |

| S2 | 20-400 | |||||

| DN100 | S1 | 20-400 | W | 13-250 | 1.6Mpa | Flange ≤6.3Mpa |

| S2 | 32-650 | |||||

Note: Additional sizes available up to DN400. Please contact us for complete specifications.

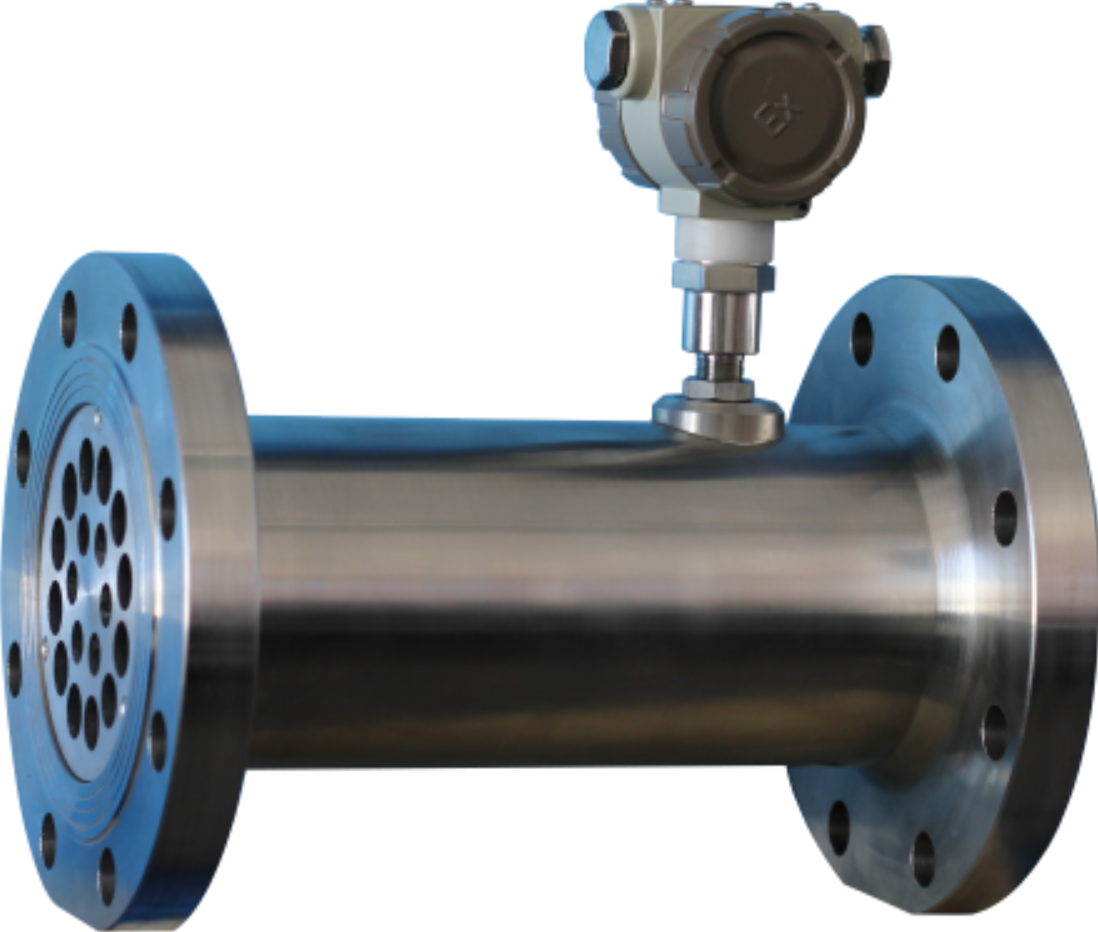

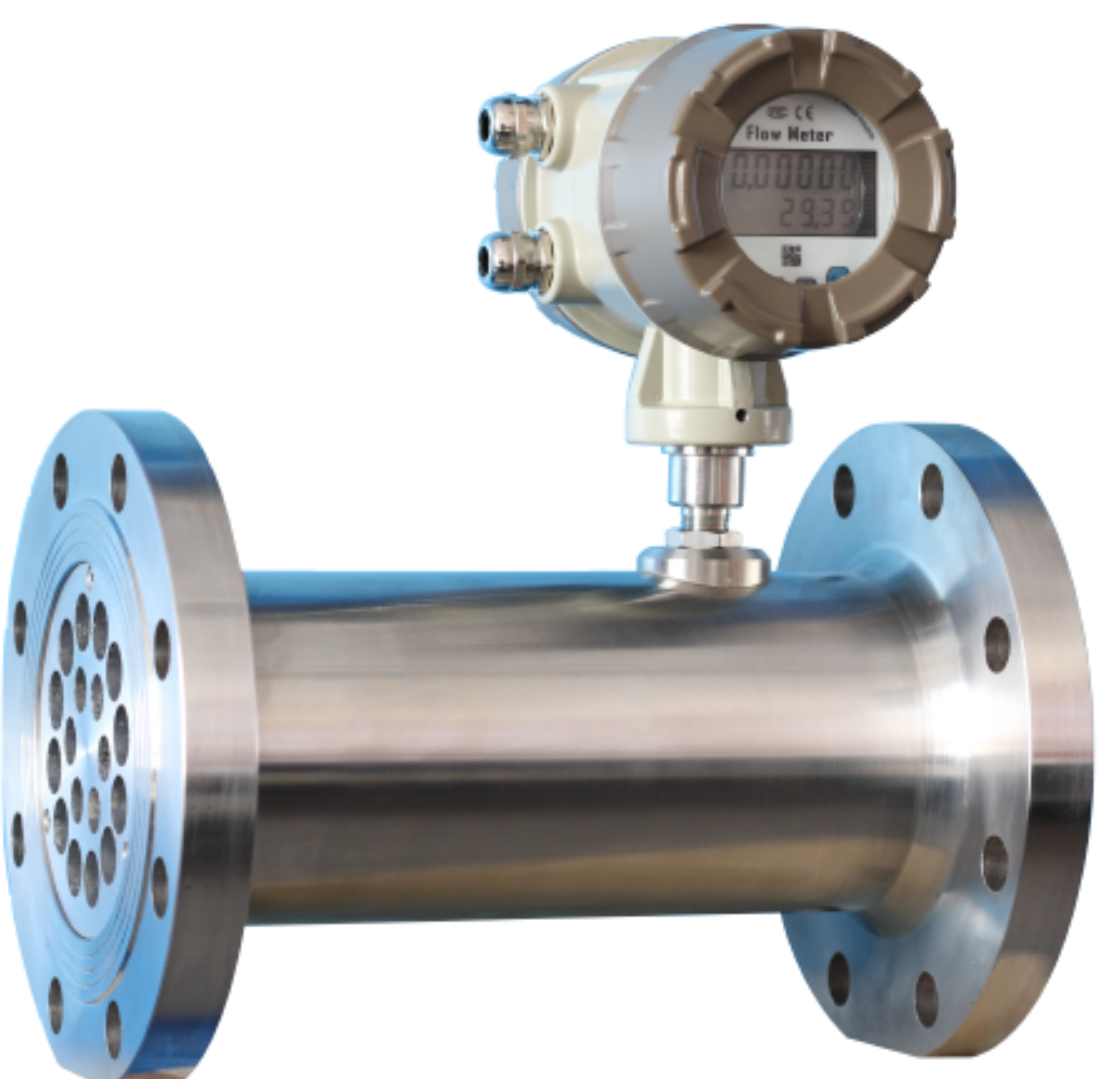

Natural Gas Turbine Flow Meter Types

| Model | SGW-N | SGW-A | SGW-B | SGW-C | SGW-D |

|---|---|---|---|---|---|

| Picture |

|

|

|

||

| Display |

No Digital Display No temperature and pressure compensation |

Digital Display Instant & Totalized Flow No temperature and pressure compensation |

Digital Display Instant & Totalized Flow Temperature and pressure compensation |

||

| Diameter | DN20-DN400 | ||||

| Output | Pulse | 4-20mA | No | 4-20mA/Pulse | 4-20mA/Pulse |

| Power | 24VDC±15% | Battery* | 24VDC±15% | 24VDC±15% & Battery | |

| Flow Range | Standard | Standard or Extended Flow range | |||

| RS485 | No | RS485 Option | |||

| Power consumption < 0.5W | |||||

English

English  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย  українська

українська  Malay

Malay  עברי

עברי  Indonesia

Indonesia  Ελλάδα

Ελλάδα  ಕನ್ನಡ

ಕನ್ನಡ  հայերեն

հայերեն

Email

Email

WA

WA

Inquiry

Inquiry