Related Products

Stainless steel flow meter can be used in harsh environment for corrosive fluids or gas measurement. It can be used in food or pharmaceutical industry for chemi...

Electromagnetic Flow Meters for Chemical Acid Measurement: Corrosion-Resistant Sensor Material SelectionIn the realm of chemical industry, accurate measurement ...

Electromagnetic flow meters can measure extremely corrosive phosphoric acid. It also includes useful technical information such as acid flow meter selection, installation instructions, etc.

Wide phosphoric acid applications needs flow measurement

Phosphoric acid has the chemical formula HPO₄. It is a very important acid that is not organic. It is a clear, colorless liquid that tastes unpleasant and can hurt you. Phosphoric acid is pretty stable at room temperature, but it may swiftly eat away at metals. Depending on how strong it is, phosphoric acid can be made into weak and strong forms. Phosphoric acid is commonly used in manufacturing at a concentration of about 85%.

In industrial, phosphoric acid is used in a lot of various ways. It is generally used to manufacture phosphate fertilizers, such as superphosphate and diammonium phosphate, which are particularly vital for producing crops. Phosphoric acid is also a common sour taste regulator and preservative in the food industry. It is also used to get rid of rust and make metal surfaces phosphatized. It is used to create a number of phosphate drugs in the pharmaceutical sector.

There are many uses for phosphoric acid, but the most popular ones are:

Wide applications of phosphoric acid flow meters

More than 80% of phosphoric acid is used by the fertilizer industry. Phosphoric acid is used to manufacture a range of phosphate fertilizers, including superphosphate, monoammonium phosphate, and diammonium phosphate. These fertilizers provide crops the phosphorus they need to flourish and are particularly vital for increasing agricultural output.

In the food industry, phosphoric acid is generally used to reduce the pH, keep food fresh, and make it more acidic. Phosphoric acid is found a lot of the carbonated drinks we drink, such cola. It can make the drink taste sour. Phosphoric acid is also used to make meat taste better and hold more water in the meantime.

Phosphoric acid is generally used in the metal business to eliminate rust and phosphatize metal. It can remove rust from the metal surface and produce a protective film of phosphate on the metal surface, which makes the metal less susceptible to corrode. Many companies, like those that make vehicles and appliances for the home, use this a lot.

In the pharmaceutical business, phosphoric acid is used to manufacture a number of phosphate drugs, such as chloroquine phosphate and codeine phosphate. These drugs are really important for getting better.

It has always been challenging to get proper phosphoric acid flow measurement result in industrial automation due of these reasons:

quite corrosive: Phosphoric acid is quite corrosive, especially to normal steel and some alloys. This corrosiveness can quickly damage the flow sensor of standard flow meters, which can make the readings less accurate and decrease the life of the device. Phosphoric acid can eat away at most metals to varied degrees.

A lot of changes in viscosity: The viscosity of phosphoric acid changes a lot depending on the temperature and concentration. The substance gets thicker as it gets colder and more concentrated. This change in viscosity can make flow meters less accurate, especially those that employ fluid dynamics to measure flow.

Change in conductivity: The conductivity of phosphoric acid changes with concentration, which can have an effect on some flow meters. Phosphoric acid does transmit electricity to some amount, but this difference in conductivity should be kept in mind while picking a flow meter.

Traditional flow meters sometimes have huge problems when they come into contact with particularly corrosive chemicals like phosphoric acid.

Phosphoric acid comes into direct touch with moving parts of mechanical flow meters like turbine flow meters and oval gear flow meters. This makes them prone to corrode and break. The increased viscosity of phosphoric acid can also change how these moving parts perform, which can lead to additional mistakes in measurements.

× Differential pressure flowmeter: Selecting corrosion-resistant materials helps mitigate corrosion issues; but it will make flow sensor price very expensive if you choose tantalum material.

Oval gear flow meter can also been corroded away by acid.

× Oval gear flow meter: oval gear flow meter is a kind of positive displacement flow meter, the wet parts of the sensor is cast iron, cast steel or stainless steel. Even though it has high accuracy for acid flow measurement, but the oval gears could easily be corroded away.

× Turbine flow meter: Turbine flowmeter can measure a single pure liquid, but phosphoric acid solution is corrosive and can corrode the impeller, making the lifespan of the turbine flowmeter very short. Therefore, it is not recommended.

A magmeter works because of Faraday's law of electromagnetic induction. When a conductive liquid like phosphoric acid solution travels through a magnetic field, it creates an induced electromotive force. The speed of the liquid flow is directly related to the strength of this electromotive force.

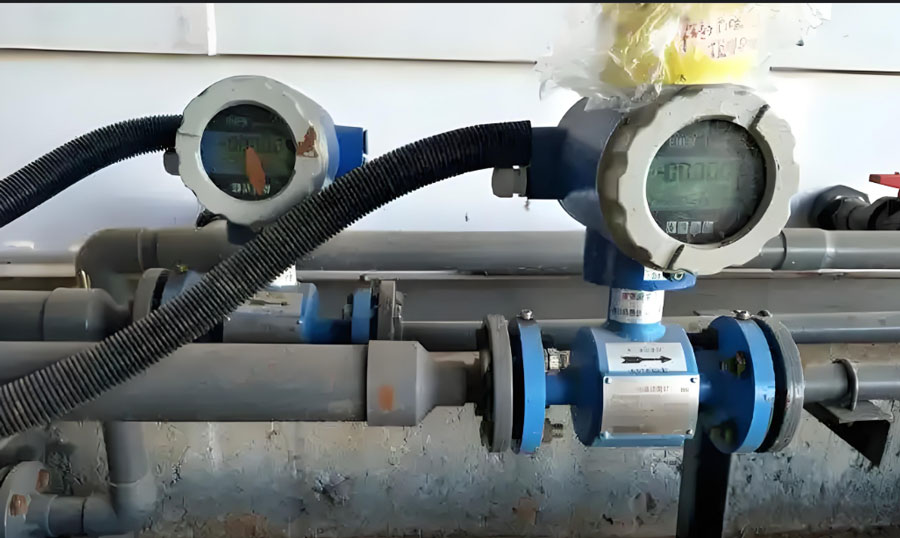

How magnetic flow meter work for phosphoric acid

To produce a magnetic field that is perpendicular to the pipeline axis, the SHD series magnetic flowmeter puts a pair of excitation coils on the measuring tube of magmeter. The Lorentz force will act on the ions in a conductive liquid, like phosphoric acid, when it flows through this magnetic field. This will make positive and negative ions migrate toward both ends of the pipeline. This will make a potential difference on the electrodes on both ends of the pipeline. The difference in potential is what causes the induced electromotive force, and its amount is directly connected to how fast the liquid flows on average.

To find the volumetric flow rate of the liquid, you can measure the induced electromotive force and multiply it by the pipeline's cross-sectional area. The liquid being measured won't be damaged by the corrosive nature of the liquid because there are no moving mechanical parts that touch it.

SHD series magnetic flowmeters are incredibly accurate and can measure phosphoric acid flows from very small flow to very large. Its pressure loss is also nearly zero, so it won't get in the way of the treatment.

When choose electromagnetic flow meters to test phosphoric acid, you should think about the following:

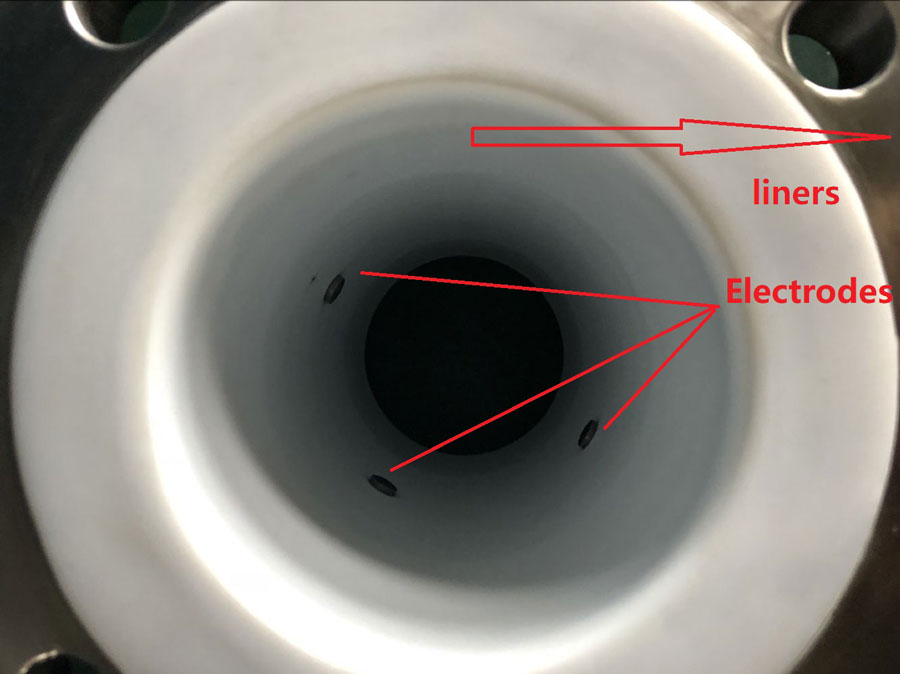

Liners and electrodes of magnetic flow meters

The most crucial thing is to pick the proper materials for the electrodes. 316L stainless steel, Hastelloy C, tantalum metal, and other materials do not corrode when they come into contact with phosphoric acid. Most amounts of liquid work well with 316L stainless steel electrodes. But if you require higher corrosion resistance or are working with high levels of phosphoric acid, it's recommended to utilize electrodes made of tantalum metal.

Choosing the lining material: The lining material on the inside of the measurement tube is just as important. Polytetrafluoroethylene (PTFE or Teflon ) is the best choice since it doesn't change the conductivity of phosphoric acid and is particularly resistant to corrosion, also PTFE(Teflon) price is cheap , however silverinstruments.com can also provide more robust liner material like PFA and F46,it can bear higher temperature around 150-160 °C.

Below we list the magmeter liner and electrodes material for different temperature and different concentration of phosphoric acid.

Electrode and Lining Material Selection Chart for Electromagnetic Flowmeters

Phosphoric Acid Compatibility

A - Suitable/Recommended | B - Usable/Acceptable | C - Not recommended | N - Not suitable | X - Corrosion resistant (for some conditions) | R - Room temperature | Sat - Saturated | (W) - Highest recommended temperature for this material

|

Fluid |

Concentration |

Temperature |

Electrode Materials |

Lining Materials |

|||||||

|

Stainless |

Hastelloy |

Titanium |

Tantalum |

Platinum |

PTFE |

PFA |

Polyurethane |

Neoprene |

|||

|

Phosphoric |

1~30 |

R |

X |

X |

X |

A |

A |

A |

A |

x |

x |

|

50 |

B |

B |

B |

B |

A |

A |

A |

A |

x |

x |

|

|

80~Sat |

140~150 |

N |

N |

N |

A |

A |

A |

A |

x |

x |

|

Flange and housing of SHD series magnetic flow meter is carbon steel in normal conditions, option with stainless steel

Choosing the housing material of magnetic flow meter: The material of the flowmeter housing and flange does not come into contact with phosphoric acid. Under normal circumstances, a carbon steel housing is sufficient. However, the environment in which the flowmeter is used can sometimes be corrosive, and users are concerned that the flowmeter housing may corrode after long-term use. silverinstruments.com offers stainless steel 304 and 316 housing options, with stainless steel housing being more resistant to corrosive environments.

Phosphoric acid does conduct electricity to some amount, but it's still vital to establish the minimum conductivity of the phosphoric acid being tested before using an electromagnetic flowmeter. Most of the time, phosphoric acid's conductivity meets all the standards for electromagnetic flow meters. But this needs to be tested for any specific diluted phosphoric acid.

Temperature and pressure rating: Pick the proper temperature and pressure rating for the conditions of the process. At greater temperatures, phosphoric acid eats away at things more quickly. This means that when you work with high temperatures, you should utilize materials that are less likely to rust.

Protection level: Since the place where phosphoric acid is generated can be harsh, it's recommended to choose electromagnetic flow meters with higher protection levels, such IP67 or IP68, to make sure they perform well in these settings.

Choose the proper amount of precision and range based on what you truly need. You can use a high-precision electromagnetic flowmeter that is accurate to ± 0.2% if you need to measure things very accurately.

When measuring things like phosphoric acid that are hard to find, it's very vital to install electromagnetic flow meters the right way so that they offer accurate values.

Install acid flow meter properly to get best measurement result

Choosing the best location to install: Put the electromagnetic flowmeter in the part of the pipeline system where the fluid fills it up. To keep bubbles from forming, it shouldn't be put near the top of the pipeline. You should also stay away from putting it in places where negative pressure is likely to happen, as this could hurt the lining.

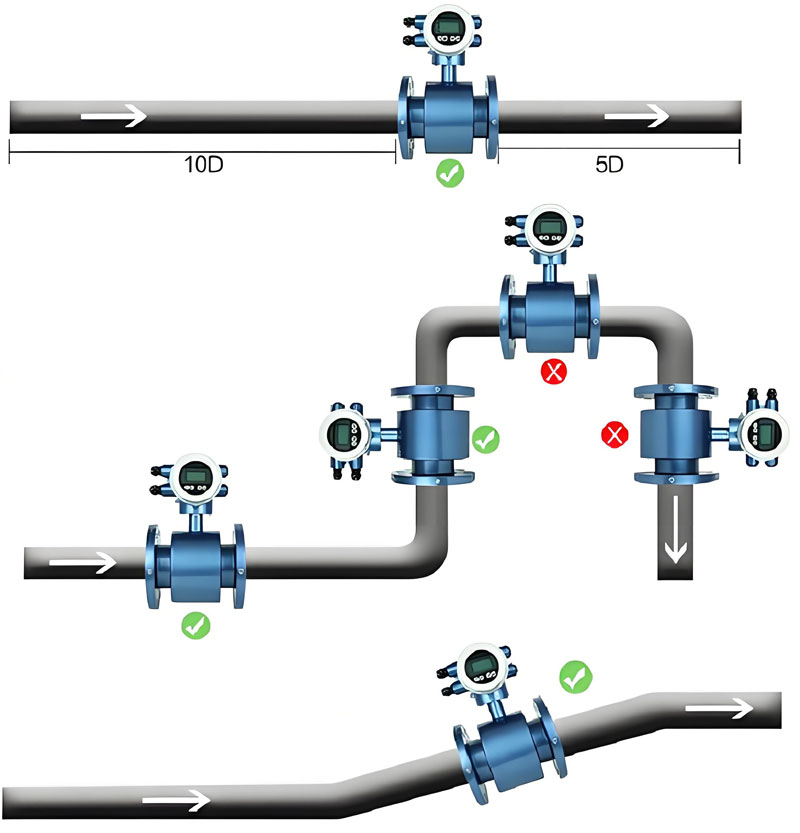

To make sure the measurements are correct, there should be enough straight pipe sections before and after the electromagnetic flowmeter. The straight pipe part that comes before the pipe should be 5 to 10 times the diameter of the pipe, and the straight pipe section that comes after the pipe should be 2 to 3 times the diameter of the pipe. The length of the straight pipe part needs to be longer if there are elbows and valves upstream that block the flow.

Grounding requirements: Electromagnetic flow meters need to be correctly grounded in order to work right. Make sure that both the equipment and the pipeline system are properly grounded. You need to put in specific grounding rings if the pipeline isn't constructed of metal or is covered in materials that don't conduct electricity. In general, phosphoric acid pipes may be plastic pipes rather than commonly used iron pipes, as phosphoric acid solutions have strong corrosiveness. When installing electromagnetic flow meters on plastic pipes, a grounding ring is required, and we need to choose a grounding ring that is the same as the electrode material.

Pipeline support: Magnetic flow meters are sometimes very heavy, especially the mag flow sensors with large diameters,such as 4” acid flow meter or 6 inch acid flow meter. To minimize the stress on the flow meters body generated by the pipelines, supports need to be put up near the flow meters sensors.

Electrical connection: Follow the manual books that together with the SHD series magnetic flowmeter to connect it to power supply, kindly note the name plate on the flow meter, whether it is 24VDC or 220V AC. Pay special attention to how the signal cable is grounded and transferred. Electromagnetic compatibility issues should be given more consideration when there is a lot of electromagnetic interference.

Pay attention to the name plate of the acid flow meter.

Maintenance: When you install the electromagnetic flowmeter from silverinstrument.com, you need to think about how it will need to be maintained in the future and make sure there is enough space around it for engineer inspection and do the routine maintenance work. .

Because of how it works and how it is made, the electromagnetic flowmeter is the ideal technique to measure the flow rate of phosphoric acid. There are no moving parts in it, and phosphoric acid won't eat it away. It is very stable, has low pressure loss, and may be used for many things.

When choosing and using an electromagnetic flowmeter to measure phosphoric acid, the most important thing is to choose the proper materials, especially for the lining and electrodes. Also, proper installation and maintenance are important to make sure that equipment functions properly and stays stable over time.

Electromagnetic flowmeters will keep getting better at measuring corrosive media as technology improves. This will make them a better way to quantify things like phosphoric acid that are chemicals.

we will contact you within 24 hours.