Related Products

Large size: 4 inch,5 inch, 6 inch, 8 inch, 10 inch,12 inch.Max flow range: 1000 ton/hour.Option with high pressure design.Direct mass flow crude oil, fuel and s...

What is crude oil flow meter?A crude oil flow meter is a device used to measure the flow rate of crude oil in pipelines or other transportation systems. The flo...

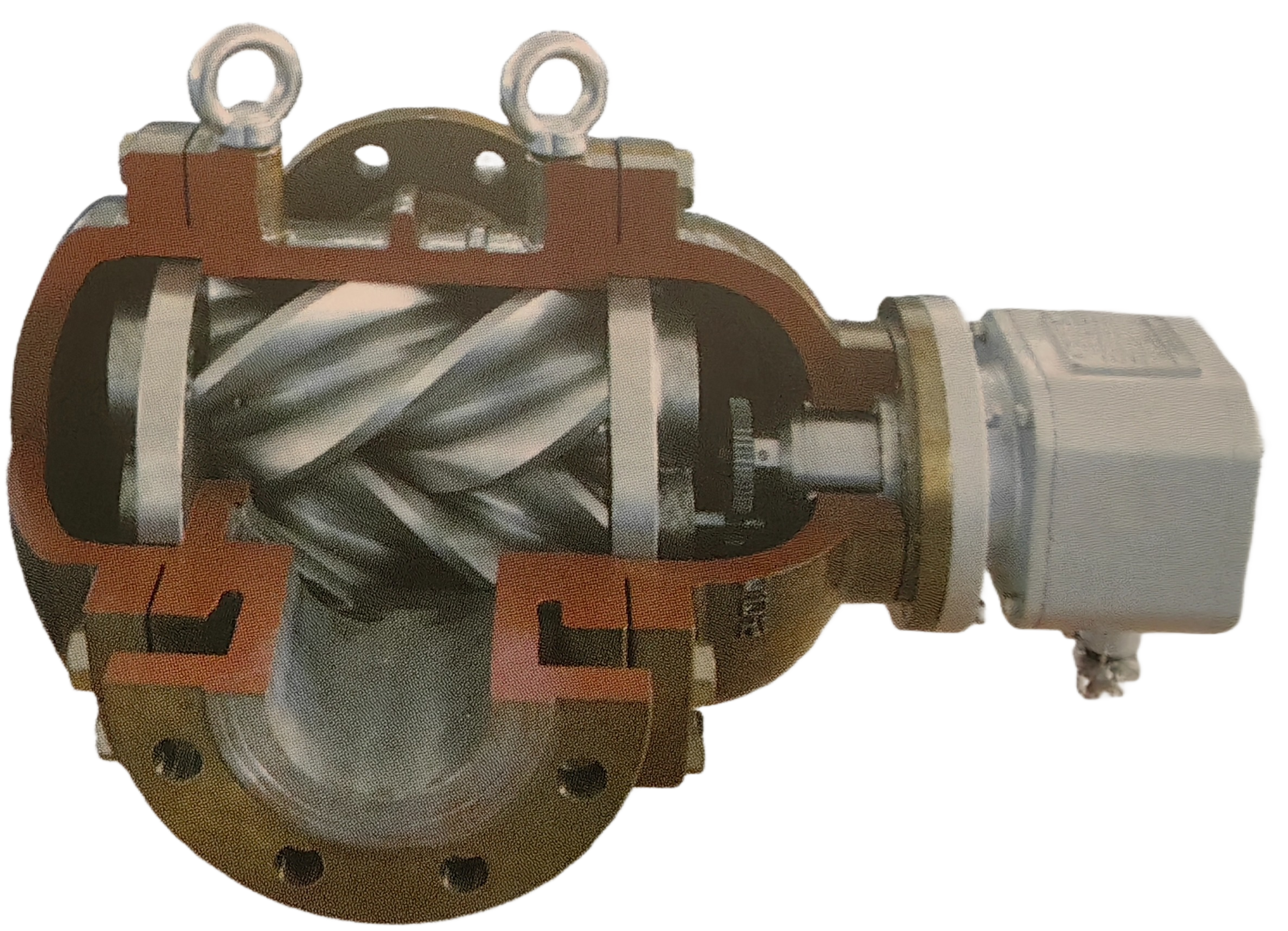

While smaller positive displacement (PD) flow meters such as 2-inch, 3-inch, or 4-inch models are common, a 12-inch (DN300) positive displacement flow meter is far harder to source. Only a few manufacturers can build large-capacity PD meters with reliable performance. Silver Automation Instruments is one of them. Our 12-inch helical gear flow meter is engineered for fuel, oil, crude oil, and diesel, delivering accurate volumetric measurement for demanding industrial applications.

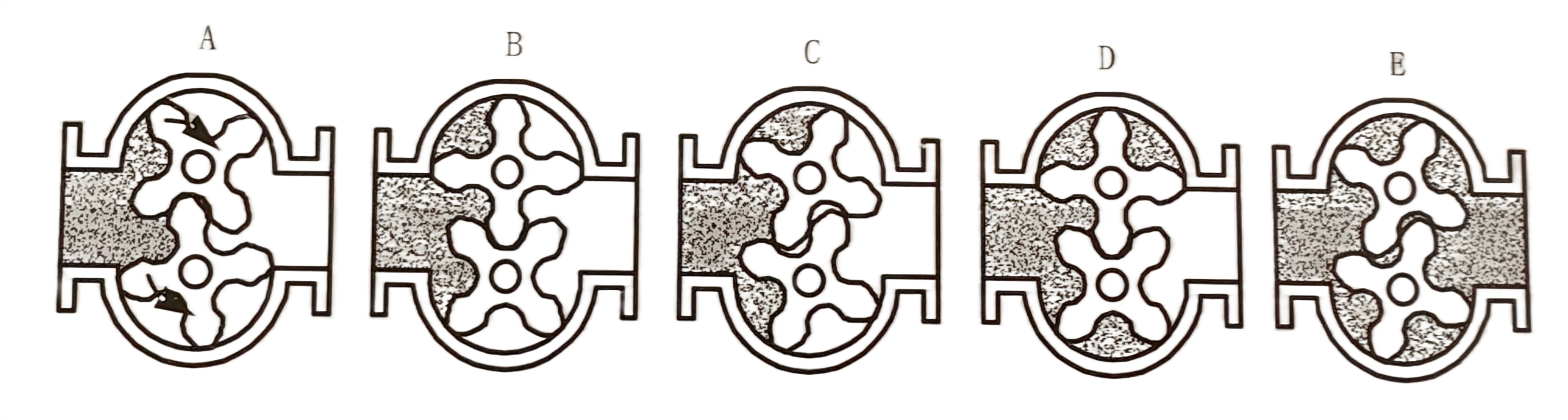

A positive displacement (PD) flow meter divides fluid into fixed, repeatable volumes. In a helical gear flow meter, two precisely machined helical rotors spin within a measuring chamber as the liquid passes through. Each full rotation displaces a fixed base volume, so the total number of rotations is directly proportional to the volumetric flow.

Because the rotors do not contact each other or the chamber walls, mechanical wear is minimal and service life is extended. The helical profile ensures smooth, low-pulsation flow, reducing vibration/pressure ripple that could affect downstream instruments or control valves. This yields lower noise, more stable signals, and precise data for automated control—ideal for oil and fuel metering where stable readings and long-term repeatability are critical.

These strengths make the 12-inch PD meter a versatile choice for petroleum refining, chemical processing, power generation, marine fueling, and bulk liquid logistics.

A 12-inch mechanical flow meter is ideal for high-volume transfer of diesel, fuel oil, crude oil, and other hydrocarbons. Its helical gear chamber provides smooth, low-pulsation measurement even at high rates (up to ~900 m³/h, viscosity-dependent). The mechanical register gives a direct visual display—reliable for sites lacking external power. Built with carbon steel and stainless steel, the meter is engineered for long life in harsh environments, from loading terminals to fuel depots and oil distribution systems.

Each unit comprises a precision flow sensor, an accuracy adjuster, a mechanical or digital register, and a signal transmitter. Timing gears are located outside the measuring chamber to synchronize the rotors without internal contact. Optional heating jackets (hot water/oil/steam, typically ≤200 °C) help keep viscous liquids at optimal conditions without damaging the meter body. Available pressure classes include PN16, PN25, PN40, and 6.3 MPa (model-specific). Single-body or double-body designs are available to match flow and installation needs.

The following values are examples based on common applications and do not represent all industry conditions.

| Fluid Type | Dynamic Viscosity Range | Viscosity Unit | Typical Flow Range (m³/h) | Notes |

|---|---|---|---|---|

| Gasoline | 0.3 – 0.8 | cP (≈ mPa·s) | 250 – 800 | Low-viscosity hydrocarbon fuel |

| Kerosene | 0.8 – 2 | cP | 220 – 900 | Medium-light fuel oil |

| Diesel / Engine Oil | 2 – 15 | cSt | 180 – 900 | Moderate-viscosity mineral oil |

| Heavy Fuel Oil | 14 – 400 | mPa·s | 180 – 900 | High viscosity; heating recommended |

| Very Viscous Liquids | 400 – 2000 | cP | 150 – 600 | Thick chemical/polymer fluids |

| Ultra-High Viscosity Liquids | 2000 – 3500 | mPa·s | 110 – 450 | Requires strong pumping capacity |

As an experienced flow meter manufacturer in China, Silver Automation Instruments supplies positive displacement, turbine, Coriolis mass, and magnetic flow meters worldwide. We focus on cost-effective, high-performance products with responsive technical support. Every meter is tested prior to shipment, and our quality system complies with international standards (e.g., ISO 9001, CE).

The 12-inch (DN300) helical gear PD flow meter from Silver Automation Instruments delivers accurate, stable volumetric measurement for oil, fuel, and other bulk liquid applications. With rugged materials, flexible I/O, jacket options, and simplified servicing, it offers the reliability and total cost of ownership industrial users expect.

Whether you manage an oil distribution network, a fuel storage facility, or a chemical transfer line, our 12-inch PD meter ensures every drop counts—accurately and efficiently.

The typical face-to-face length for a 12-inch (DN300) positive displacement flow meter is 800 mm.

The approximate net weight is about 890 kg. Final shipping weight may vary with options and materials.

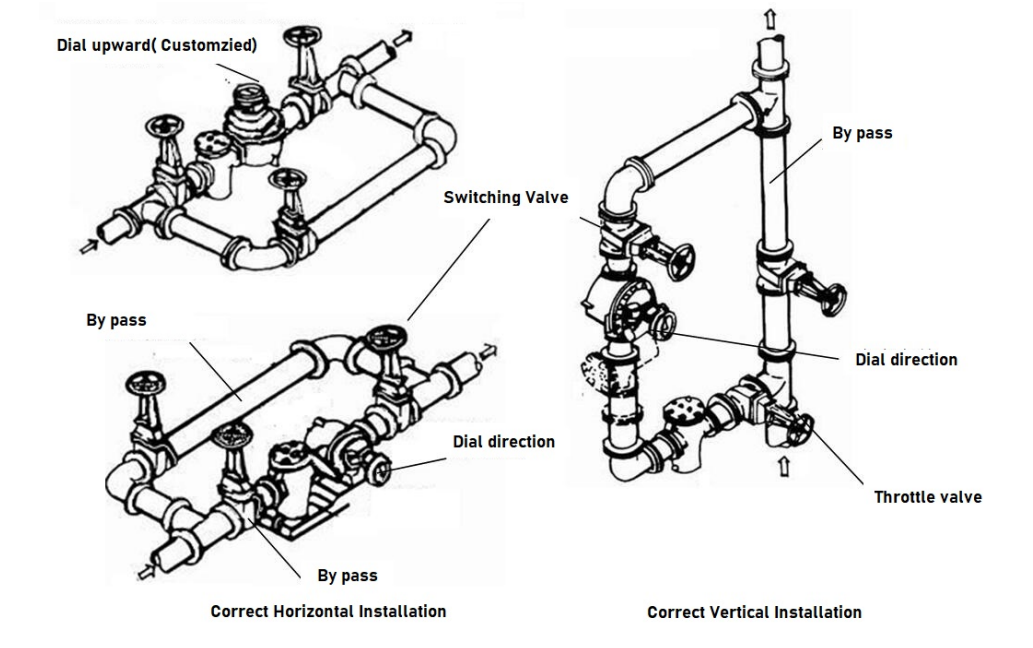

No straight run is required. Unlike many velocity-type meters, a helical gear PD flow meter does not need upstream/downstream straight lengths.

Yes. A mechanical register is available for power-free local indication. Electronic transmitters are also optional.

Yes. We can provide pulse, 4–20 mA, and MODBUS RTU outputs. Please specify your I/O requirements when ordering.

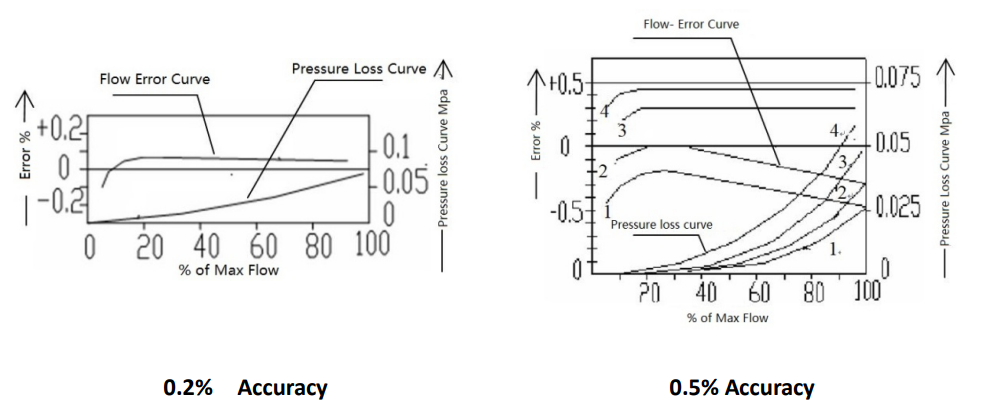

Yes. Pressure drop charts/curves can be supplied upon request to match your viscosity, flow rate, and fluid temperature. Below is pressure loss curve for your reference.

we will contact you within 24 hours.