Proper Installation of Gas Turbine Flow Meters

Gas turbine flow meter

Proper install of gas turbine flow meter to get best measurement result

Getting accurate results depends not only on choosing the right meter for the customer’s process, but also on correct installation. The following guide explains, step by step, how to install a gas turbine flow meter properly.

Installing a gas turbine meter correctly affects both measurement performance and pipeline safety. Only qualified technicians with piping and hazardous-area competence should perform the work. Follow local codes and site procedures, and never open flanges or housings while the line is pressurized. In Ex areas, preserve explosion-proof integrity—use certified glands and never modify cable entries or sealing methods.

A turbine meter needs a clean, stable flow profile. Before you bolt anything up:

Orientation & direction. Gas turbine meters are typically installed horizontally with the flow arrow matching the gas direction. Keep the body level and free from piping strain.

Straight runs (velocity profile). Provide at least 10 DN upstream and 5 DN downstream of straight pipe. If you have elbows in plane, reducers, control valves, or tees just upstream, extend upstream straight run to 15–20 DN, or add a flow conditioner to restore a symmetric profile. Keep gaskets flush with the bore—no gasket overhangs or intrusion from welds into the metering tube.

Coaxial alignment. Align flanges coaxially at the inlet and outlet. Misalignment creates swirl and uneven velocity, accelerating bearing wear and adding measurement error.

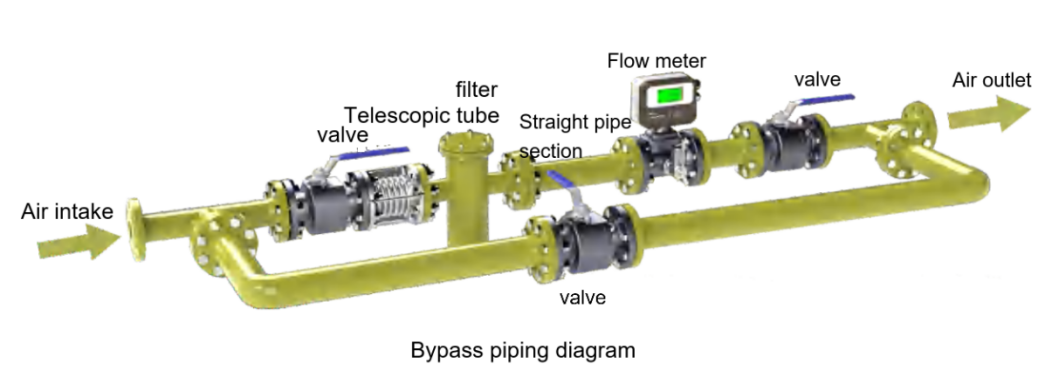

Bypass loop. Install a bypass line with isolation valves around the meter so you can service the instrument without shutting the plant. During normal operation, lock the bypass closed.

Pressurization ramp rate. Open the upstream valve slowly and increase pressure gradually. The maximum pressure-rise rate should not exceed 35 kPa per second. Rapid pressurization can overspeed the rotor and damage bearings.

Leak check & rotation. After pressurization, check for leaks at all joints. Verify the rotor turns freely (via diagnostics or pulse frequency at low flow) without vibration or noise.

Flow stabilization. Bring the line up to normal pressure and temperature before final zeroing or verification. If the process frequently runs near the minimum flow, consider a smaller meter or a multi-path solution to maintain linearity and repeatability.

Cable type. Use twisted-pair shielded cable for 4–20 mA/HART or pulse outputs. Keep signal cables in a separate conduit from power lines. If a conduit entry can’t be sealed, orient it downward to prevent condensation.

Shielding & grounding. Ground the cable shield at one end only (typically the control room) to avoid loops. Ground the meter per the manufacturer—do not share instrument ground with high-voltage systems. During pipeline welding, never use the meter as a welding return.

Ingress protection. Seal unused entries with approved plugs. Add a drip loop in humid environments to prevent moisture from wicking into the terminal box.

Routine checks prolong meter life and preserve accuracy:

Turbine bearings need timely and effective lubrication. Proper lube improves wear and corrosion resistance and flushes fine particles, preserving linear accuracy and repeatability.

|

Nominal Diameter (DN) |

25 |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

|

First-time / daily refueling (mL) |

10 / 5 |

10 / 5 |

10 / 5 |

10 / 5 |

10 / 5 |

15 / 10 |

15 / 10 |

15 / 10 |

15 / 10 |

15 / 10 |

Turbine meters excel on clean, dry gases with good Reynolds numbers and offer pulse outputs for totalization and custody transfer. For other scenarios:

Q1: What straight-run lengths

are required for gas turbine flow meters?

A: Provide ≥10 DN upstream and ≥5 DN downstream of

straight pipe. If elbows, tees, or control valves are immediately upstream,

extend to 15–20 DN or install a flow conditioner.

Q2: How fast can I ramp pressure

during startup?

A: Keep the pressure-rise rate ≤ 35 kPa/s to prevent rotor

overspeed and bearing damage.

Q3: Do turbine meters work

with pulsating flow?

A: Not recommended. Use dampeners, relocate to a stable section,

or consider Coriolis for pulsating lines.

Q4: How often should I

lubricate a gas turbine flow meter? And how to lubricate it ?

A: Typically 10–15 times per year, with volumes per DN size (see table). Increase frequency for high-pressure, high-flow, or dirty service.

Q5: What wiring practices

prevent noisy signals?

A: Use twisted-pair shielded cable, ground the shield at one

end only, keep signal cables away from power/VFD lines, and seal

conduits to avoid condensation.

Following these gas turbine flow meter practices—clean piping, correct straight runs, stress-free mounting, controlled startup, robust EMI/grounding, and disciplined lubrication—delivers stable accuracy, longer bearing life, and safer pipeline operation. Where process conditions challenge turbine technology (pulsation, very low velocity, composition shifts), evaluate Coriolis, ultrasonic, or thermal mass alternatives.