In-line flow meters which suitable for

natural gas flow metering include

gas turbines flow meter,

vortex flow meters and

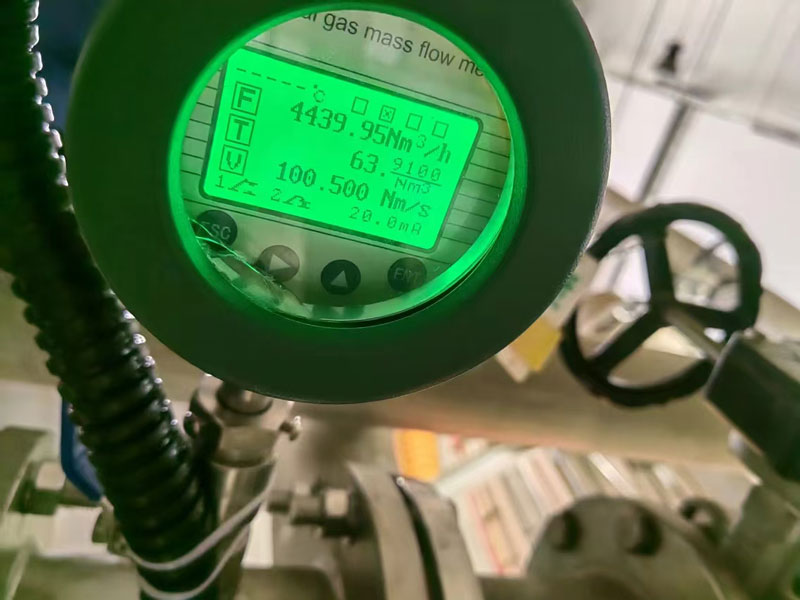

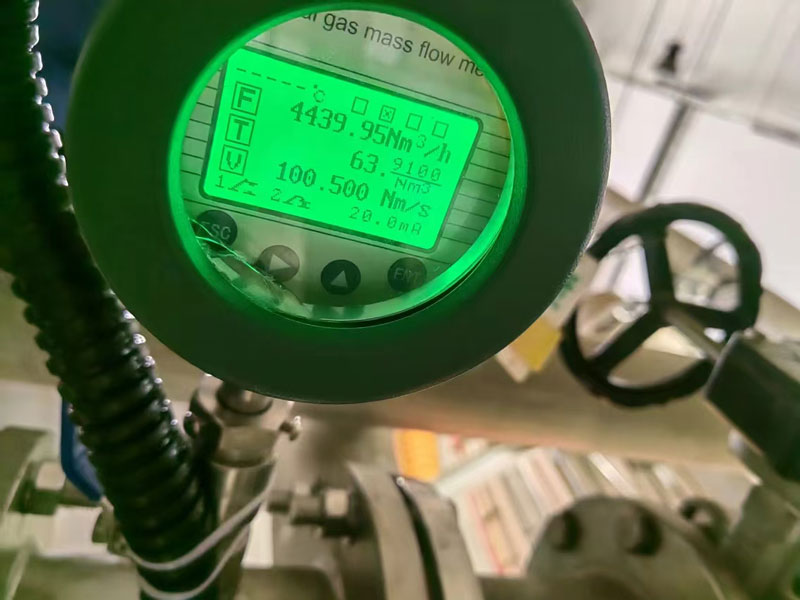

thermal dispersion flow meter. These in-line natural gas flow meters all have electronic display that shows natural gas instantaneous flow and cumulative flow .In-line natural gas flow meters are also divided into volumetric flow meters and mass flow meters.Silver Automation Instruments sell low price

digital natural gas flowmeter with fast lead time and rugged quality.Natural gas is a kind of fuel gas, the main component of natural gas is CH4 (methane), which is colorless, odorless, non-toxic and non-corrosive. It also includes certain amounts of ethane, propane and heavy hydrocarbons, as well as small amounts of nitrogen, oxygen, carbon dioxide and vulcanization. Natural gas ignites to produce H2O (water).

Silver offers digital natural gas flow meter with electronic display

In-line gas turbine flow meter for natural gas volumetric flow measurement

When the natural gas flows through the turbine flow sensor, the turbine is forced to rotate under the action of the fluid thrust, and its rotation speed is proportional to the average flow velocity of the natural gas. The rotation of the turbine periodically changes the magnetic resistance value of the magnetoelectric converter, and the magnetic flux in the detection coil is followed. A periodic change occurs, producing a periodic electrical pulse signal. The electrical pulse signal is proportional to the volumetric flow of fluid flowing through the turbine flow sensor over a range of flow rates (Reynolds numbers).

Gas turbine flow meter for natural gas

How turbine flow meters work for natural gas?

When the natural gas flows through the turbine flow sensor, the turbine is forced to rotate under the action of the fluid thrust, and its rotation speed is proportional to the average flow velocity of the natural gas. The rotation of the turbine periodically changes the magnetic resistance value of the magnetoelectric converter, and the magnetic flux in the detection coil is followed. A periodic change occurs, producing a periodic electrical pulse signal. The electrical pulse signal is proportional to the volumetric flow of fluid flowing through the turbine flow sensor over a range of flow rates (Reynolds numbers).

In-line Gas turbine flow meter advantage:

✔ In-line gas turbine flow meters from DN20(3/4 inch) to DN400 (16 inch)

Different natural gas turbine flow meter sizes and flow range:

|

Size

(mm)

|

Standard

(m3/h)

|

Extended

(m3/h)

|

|

DN20

|

S

|

2-20

|

W

|

4-40

|

|

DN25

|

S

|

2.5-25

|

W

|

4-40

|

|

DN32

|

S

|

4-40

|

W

|

6-60

|

|

DN40

|

S

|

5-50

|

W

|

6-60

|

|

DN50

|

S1

|

6-65

|

W1

|

5-70

|

|

S2

|

10-100

|

W2

|

8-100

|

|

DN65

|

S

|

15-200

|

W

|

10-200

|

|

DN80

|

S1

|

13-250

|

W

|

10-160

|

|

S2

|

20-400

|

|

DN100

|

S1

|

20-400

|

W

|

13-250

|

|

S2

|

32-650

|

|

DN125

|

S

|

25-700

|

W

|

20-800

|

|

DN150

|

S1

|

32-650

|

W

|

80-1600

|

|

S2

|

50-1000

|

|

DN200

|

S1

|

80-1600

|

W

|

50-1000

|

|

S2

|

130-2500

|

|

DN250

|

S1

|

130-2500

|

W

|

80-1600

|

|

S2

|

200-4000

|

|

DN300

|

S

|

200-4000

|

W1

|

130-2500

|

|

W2

|

320-6500

|

|

DN350

|

S

|

400-8000

|

W1

|

150-4500

|

|

W2

|

300-9000

|

|

DN400

|

S

|

500-10000

|

W1

|

300-9000

|

|

W2

|

500-10000

|

DN400(16 inches) in line turbine flow meter

✔ High accuracy :±1%R~±1.5%R

✔ Good repeatability, short-term repeatability of 0.05% to 0.2%

✔ Output pulse frequency signal for total metering and connection to a computer or output 4-20mA with instant natural gas flow rate.

✔ No zero drift, strong anti-interference ability.

✔ High frequency signal (3~4kHz) can be obtained, and the signal resolution is strong

✔ Compact and lightweight, easy to install and maintain

✔ Suitable for high pressure natural gas flow measurement,such as 300 psi ,600 psi or 1000 psi high pressure gas flow meter.

Disadvantages of using inline turbine flow meter for natural gas

× Dependence on clean gas: Impurities (droplets, dust) can damage the blades.

× Regular lubrication/maintenance is required: bearing wear affects its lifespan. However Silvelinstersens.com has innovated a self-lubricating gas turbine flow meter, which comes with a small bottle of lubricating oil. Engineers can easily lubricate the impeller with just a gentle press.

× Pressure loss: The rotation of blades generates pressure drop (taking into account pipeline pressure).

In-line Turbine flow meter application overview:

Turbine flow meters are widely used in the following measuring media: petroleum, organic liquids, inorganic liquids, liquefied gases, gas and cryogenic fluids. Gas turbines can be used to measure air, oxygen, nitrogen, gas, natural gas, gas, hydrogen, liquefied petroleum gas, flue gas, methane, butane, chlorine, gas, biogas, carbon dioxide, nitrogen, acetylene, phosgene, oxygen and so on.

Typical applications for turbine type natural gas flow meter

✔ Urban gas gate stations, gas pipeline trade metering, CNG refueling stations.

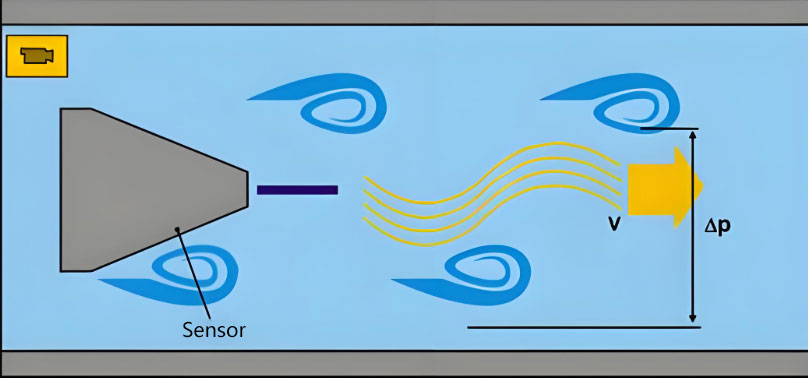

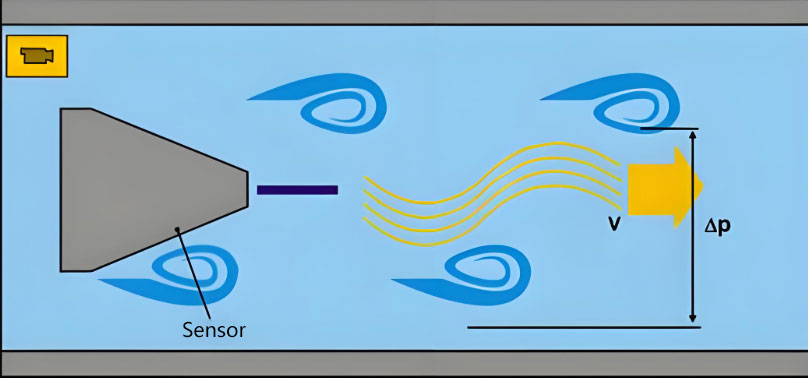

Vortex shedding flow meter for fuel gas flow rate measurement

How Vortex flow meter works for natural gas flow measurement?

How Vortex flow meter works for natural gas flow measurement?

A non-streamlined vortex generator is placed in the fluid, and the fluid is alternately separated on both sides of the vortex generator to release two rows of regularly arranged vortex. Within a certain flow (Reynolds number), the separation frequency of the vortex is proportional to the volumetric flow of the fluid flowing through the vortex flow sensor.

How vortex flow meter works for natural gas

Vortex flow transmitter advantage:

✔ In-line vortex flow meter from DN20 to DN300, below table we list the flow range for natural gas:

|

Vortex sensor size

(mm)

|

Natural gas flow range (m3/h

|

|

Std.flow range

|

Exd.flow range

|

|

15

|

4-16

|

3-20

|

|

20

|

5-30

|

4-40

|

|

25

|

8-80

|

5-90

|

|

32

|

10-150

|

6-200

|

|

40

|

14-280

|

9-310

|

|

50

|

20-400

|

14-490

|

|

65

|

35-720

|

24-840

|

|

80

|

55-1100

|

36-1440

|

|

100

|

80-1600

|

60-2440

|

|

125

|

130-2600

|

90-3600

|

|

150

|

190-3800

|

130-5200

|

|

200

|

330--6600

|

220-7700

|

|

250

|

530-10600

|

350-12400

|

|

300

|

760-15200

|

500-17800

|

|

350

|

1035-21000

|

690-24000

|

|

400

|

1350-27000

|

900-31000

|

✔ The structure is simple and firm, and vortex type natural gas flow meter is cheaper than mass flow meters and turbine flow meters.

Vortex flow meter construction sensor is simple but robust

✔ The maintenance is convenient and easy

✔ Suitable for a wide variety of fluids, such as liquids, gases, vapors and partially miscible fluids

✔ Measuring natural gas with high precision, generally ±1%R~±2%R

✔ Wide turn down range, up to 20:1~10:1

✔ Output pulse frequency signal, suitable for total metering and connection with computer, no zero drift, option with 4-20mA,RS485 MODBUS

✔ Vortex flow meter is better for middle to high pressure rating, high pressure natural gas measurement is more stable.

Disadvantages of vortex flow meter for natural gas:

× Low flow rate insensitive: Small flow rates result in large errors,while thermal mass flow meter has better performance on small flow rate natural gas measurement.

× Vibration interference: Pipeline vibration can easily lead to false signals.

× Straight pipe section required (front 10D, back 5D): High installation space requirements.

Typical applications for inline vortex type natural gas flow meter:

Industrial gas boiler monitoring, process control of medium and high pressure pipelines (non trade settlement).

In-line thermal gas flow meter for measuring natural gas mass flow

How in line thermal mass flow meters ( TMF) works for natural gas?

Based on the law of thermal diffusion, the heating element and temperature sensor work together. When gas flows through, it carries away heat, and the temperature difference is proportional to the mass flow rate, directly measuring the gas mass flow rate.

Thermal gas flow meters measure natural gas with the following advantages:

✔ In-line thermal mass flow meter option with thread, wafer or flange connection

✔ It can directly measure the mass flow of natural gas without the compensation or correction of temperature and pressure.

✔ Thermal gas flow meter maintains long-term measurement accuracy

✔Can detect natural gas at low flow rate with high sensitivity signal can detect low natural gas flow to 0.1 m/s, suitable for leakage detection.

✔Extremely low voltage loss: Unobstructed flow components, and low pressure loss, energy-saving

Disadvantages of TMF flow meter for natural gas:

× Afraid of moisture/oil stains: Probe contamination can cause drift.

× Not suitable for high pressure (usually<40 bar).

× Medium accuracy (± 1-2%): not used for trade settlement.

Typical applications for thermal mass type natural gas flow meter

Small flow monitoring of gas branch lines, energy management metering, industrial boiler gas supply control, and low-pressure pipeline distribution.

In line Coriolis type flow meter for natural gas

How Coriolis flow meter work for natural gas measurement?

The Coriolis Effect is generated when natural gas flows in a U-shaped vibrating tube, and the phase difference between the inlet and outlet is proportional to the natural gas mass flow rate, allowing for direct and accurate natural gas mass flow measurement.

Advantages of using Coriolis type natural gas flow meter

✔ Especially suitable for measuring natural gas flow under ultra-high pressure,such as 1000 psi, 2000 psi or even 10000 psi.

✔The accuracy is particularly high, with a gas mass flow meter accuracy of up to 0.5%, suitable for trade measurement.

✔It can be used for LNG ultra-low temperature measurement at -162 degrees Celsius.

Cryogenic LNG flow measurement

Disadvantages of Coriolis type natural gas flow meter

× Expensive: The cost is 5-10 times that of other principles gas flow meter, such as turbine flow meter, thermal mass flow meter.

× High pressure loss: The U-shaped tube structure leads to an increase in a litter higher pressure loss

× Pipe diameter limitation: The cost of large diameters (>6 ") in line type coriolis meter has increased dramatically.

× Not suitable for low pressure natural gas flow measurement

Typical applications of inline coriolis flow meter for natural gas

LNG trade handover, chemical plant raw gas metering, and precise distribution of high-pressure natural gas (such as gas storage facilities).

Related Products:

How Vortex flow meter works for natural gas flow measurement?

How Vortex flow meter works for natural gas flow measurement?

Natural gas flow meter2018/11/15Natural gas flow meter price is often been asked by our customers, and we always choose a proper type gas flow sensors for customers, the main natural gas flow meter is Thermal mass flow meter, turbine flow meter, Vortex Flow meters.VIEW

Natural gas flow meter2018/11/15Natural gas flow meter price is often been asked by our customers, and we always choose a proper type gas flow sensors for customers, the main natural gas flow meter is Thermal mass flow meter, turbine flow meter, Vortex Flow meters.VIEW In-line type thermal dispersion flow meter2019/06/14Gas mass flow measurement.

In-line type thermal dispersion flow meter2019/06/14Gas mass flow measurement. Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW

Flanged Vortex flow meter with compensation2019/07/02STLU-BPT Series Flanged Vortex flow meter with integrated temperature sensor and pressure sensor compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow measureme...VIEW Gas Turbine Flow Meter with Temp & Press. compensation2018/08/27SGW-D series Gas turbine flow meter can be used to measure clean air or gas, such as natural gas, nitrogen gas.,etc. The best part of SGW series is that it can have integral temperature and pressure c...VIEW

Gas Turbine Flow Meter with Temp & Press. compensation2018/08/27SGW-D series Gas turbine flow meter can be used to measure clean air or gas, such as natural gas, nitrogen gas.,etc. The best part of SGW series is that it can have integral temperature and pressure c...VIEW Methane gas flow meter2019/05/24Thermal mass flow meter is a kind of electronic mass flow meter sensor for methane/biogas flow rate measurement.Thermal meter uses the calorimetric measuring principle to get the accurate methane gas ...VIEW

Methane gas flow meter2019/05/24Thermal mass flow meter is a kind of electronic mass flow meter sensor for methane/biogas flow rate measurement.Thermal meter uses the calorimetric measuring principle to get the accurate methane gas ...VIEW In-line air flow meter2019/05/20Air flow rate measurement, also compressed air is vital demand in many factories, industry, lab, facilities.We, Silver Automation Instruments, have in-line air flow meters for sale, we have low price ...VIEW

In-line air flow meter2019/05/20Air flow rate measurement, also compressed air is vital demand in many factories, industry, lab, facilities.We, Silver Automation Instruments, have in-line air flow meters for sale, we have low price ...VIEW Micro-Flowrate Thermal Mass Flow Meter2018/03/02Micro-flowrate Thermal mass flow meter

Micro-Flowrate Thermal Mass Flow Meter2018/03/02Micro-flowrate Thermal mass flow meter Thermal mass flow meter2019/06/14Low cost flow meter for gas and air

Thermal mass flow meter2019/06/14Low cost flow meter for gas and air Wafer Vortex flow meter with compensation2019/07/02STLU-BPT wafer style process connection vortex shedding flow meter with integral temperature and pressure compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow ...VIEW

Wafer Vortex flow meter with compensation2019/07/02STLU-BPT wafer style process connection vortex shedding flow meter with integral temperature and pressure compensation is a perfect choice for gas or steam (saturated steam and overheated steam) flow ...VIEW Wafer type Vortex flow meter2019/07/02STLU-2-B0 Series Wafer Vortex flow meter is a volumetric flowmeter that measures the volumetric flow rate of a gas, steam or liquid, the principle of Karman vortex. It is mainly used for flow measurem...VIEW

Wafer type Vortex flow meter2019/07/02STLU-2-B0 Series Wafer Vortex flow meter is a volumetric flowmeter that measures the volumetric flow rate of a gas, steam or liquid, the principle of Karman vortex. It is mainly used for flow measurem...VIEW Gas Flow meter2018/11/14Gas flow meter is a kind of flow measuring instruments that measure the flow of a gas. This article talks about mainly gas flow instruments such as thermal mass flow meter, vortex shedding flow sensor ,turbine flowmeter,rotameter.VIEW

Gas Flow meter2018/11/14Gas flow meter is a kind of flow measuring instruments that measure the flow of a gas. This article talks about mainly gas flow instruments such as thermal mass flow meter, vortex shedding flow sensor ,turbine flowmeter,rotameter.VIEW Industrial air flow meter2019/07/16We supply various industrial air flow meters, such as gas turbine flow meter, thermal mass flow meter, vortex flow meter at different price cost and functions.Compressed air is a very useful part of m...VIEW

Industrial air flow meter2019/07/16We supply various industrial air flow meters, such as gas turbine flow meter, thermal mass flow meter, vortex flow meter at different price cost and functions.Compressed air is a very useful part of m...VIEW