In the heart of modern industry—from power plants and oil refineries to chemical reactors and metallurgical foundries—processes often operate under extreme conditions. Measuring the flow of liquids and gases at high temperatures is one of the most significant challenges in process instrumentation. Standard flow meters can fail catastrophically when exposed to intense heat, leading to inaccurate data, process downtime, and safety hazards.

High temperature steam flow meter

Successfully managing these applications requires specialized high-temperature flow meters, engineered with robust materials and innovative designs to deliver accuracy and reliability where others cannot.

Silver Automation Instruments offers a comprehensive portfolio of high-performance flow sensors designed for the most demanding thermal environments. This guide explores the different technologies available and highlights their ideal applications, helping you select the perfect instrument for your high-temperature process.

Why is High-Temperature Flow Measurement a Challenge?

-

Measuring hot fluids presents several technical hurdles:

-

Material Limitations: Standard flow sensor components, seals, and electronics can degrade, warp, or melt at high temperatures.

-

Fluid Property Changes: The density and viscosity of fluids change dramatically with temperature, which can cause significant inaccuracies in flow meters that don't compensate for these shifts.

-

Electronics Integrity: Sensitive transmitter electronics must be protected from the intense heat of the process fluid to prevent signal drift and premature failure.

Selecting the Right High-Temperature Flow Meter Technology

Choosing the correct technology is crucial. Each type of flow meter has a unique operating principle and design features that make it suitable for specific high-temperature applications. Most high-temperature sensors from silverinstruments.com are customized solutions, not standard off-the-shelf products.

Below is a comparison of the maximum fluid temperatures for different flow meter types offered by Silver Automation Instruments.

Vortex Flow Meters (Up to 500°C / 932°F)

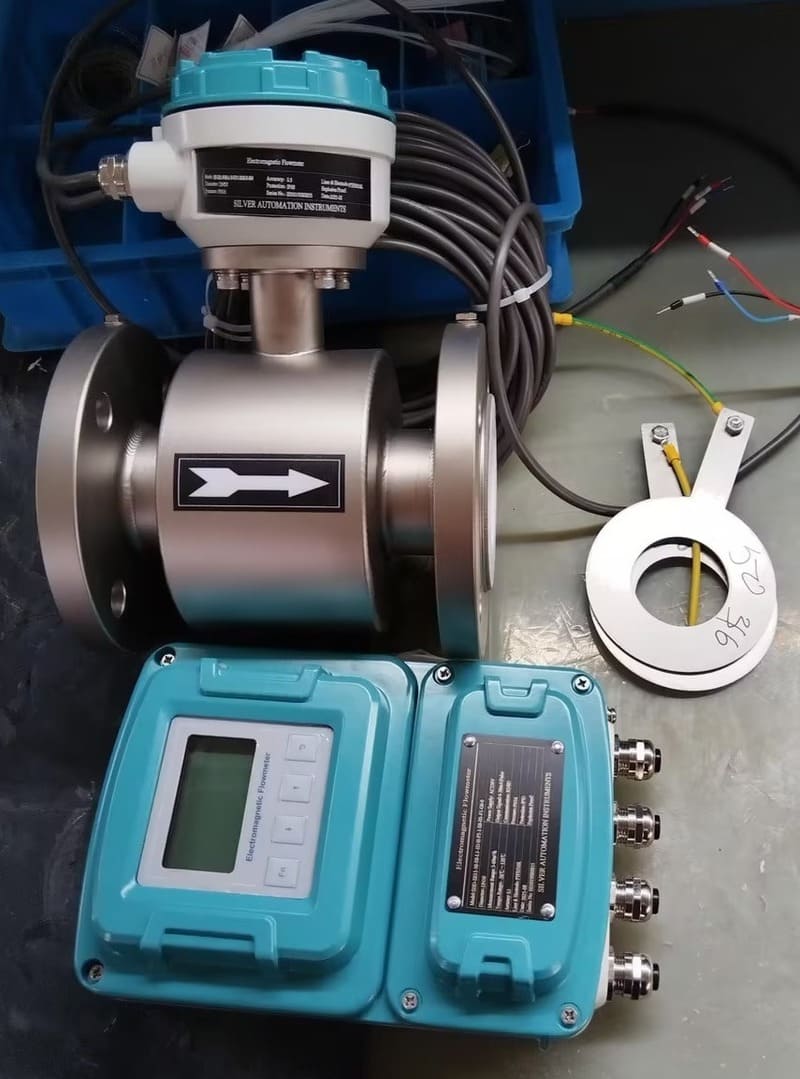

Vortex meters are a leading choice for high-temperature applications due to their simple, robust design with no moving parts. They measure flow by detecting the frequency of vortices shed from a bluff body in the flow path. Constructed entirely from durable metals like stainless steel, they are inherently suited for measuring hot liquids, gases, and, most notably, steam.

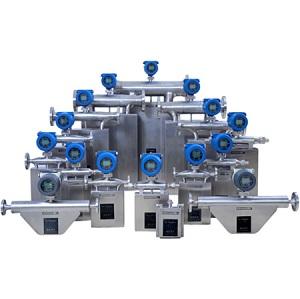

Coriolis Mass Flow Meters (Up to 450°C / 842°F)

Coriolis meters directly measure mass flow, making them immune to inaccuracies caused by temperature-induced changes in fluid density and viscosity. Special high-temperature models are designed with specific tube materials and sensor configurations to operate reliably at extreme temperatures, providing the highest accuracy for critical processes,we use to measure high temperature bitumen or liquid lithium/sodium.

Thermal Mass Flow Meters (Up to 300°C / 572°F)

Designed for gases, thermal mass flow meters use heated sensors to measure mass flow based on the principle of heat transfer.

High-temperature mass flow sensor versions feature robust sensor probes to handle hot air, flue gas, and other challenging gas streams in ducts and stacks.

Differential Pressure (DP) Flow Meters (Up to 800°C / 1472°F)

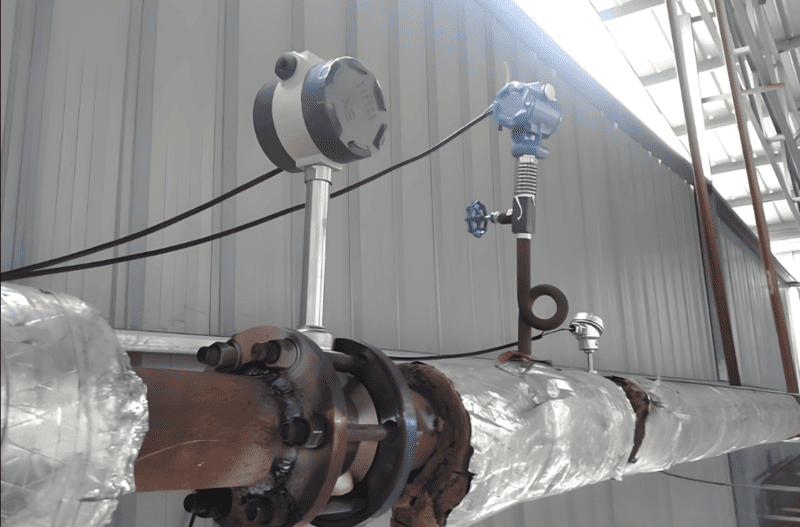

This is one of the most robust and versatile flow measurement technologies. By using a durable primary element—such as an orifice plate , Annubar , or conditioning orifice plate —to create a pressure drop, the sensitive electronic transmitter can be mounted remotely. This design allows DP systems, with the correct materials, to measure fluids at extreme temperatures. It is a proven solution for challenging applications like hot oil, viscous asphalt, and dirty flue gas.

Metal Tube Rotameters / Variable Area Flow Meters (Up to 300°C / 572°F)

These are simple, reliable mechanical flow meters (option has rotameter with transmitter). The all-metal construction of a variable area flow meter allows it to handle significant process heat. They are a cost-effective solution for local flow indication in applications like boiler feed water, hot oil, and cooling circuits where a simple, robust meter is needed.

Oval Gear Flow Meters (Up to 200°C / 392°F)

As positive displacement meters, oval gear flow meters excel at measuring viscous liquids. High-temperature versions are available for applications like hot oil, fuel, and resin measurement, where both high viscosity and high temperature are present.

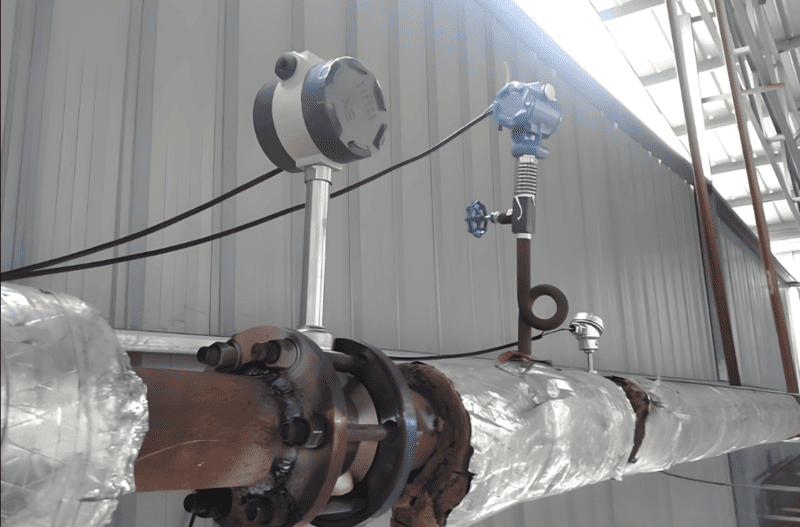

Magnetic Flow Meters (Up to 160°C / 320°F)

While not suited for the highest temperatures, magnetic flow meters with PFA or PTFE liners can handle moderately hot conductive liquids. They are a common choice for hot water applications, chemical processing, and sanitary processes that involve high-temperature cleaning cycles.

Liquid Turbine Flow Meters (Up to 150°C / 302°F)

Standard turbine flow meters are generally limited in their temperature range. However, they can be configured for applications like hot water or refined fuels at moderate temperatures.

Gas Turbine Flow Meters (Up to 80°C / 176°F)

Standard gas turbine meters are typically used for custody transfer of natural gas at ambient temperatures and are not designed for high-temperature processes.

High-Temperature Flow Meter Technology Comparison

|

Flow Meter Type

|

Commonly Measured Media

|

Max Temp (°C)

|

Max Temp (°F)

|

|

Vortex Flow Meter

|

Steam, Compressed Air, Hot Gases, Hot Water,thermal oil

|

500°C

|

932°F

|

|

Differential Pressure (DP)

|

Steam, flue gas ,hot water,

|

800°C

|

1472°F

|

|

Coriolis Mass Flow Meter

|

Oils, Chemicals, LNG, Food Products, Slurries

|

450°C

|

842°F

|

|

Thermal Mass Flow Meter

|

Hot Air, Flare Gas, Nitrogen, Biogas,Natural gas

|

300°C

|

572°F

|

|

Metal Tube Rotameter

|

Water, Air, Chemicals, Nitrogen Purge

|

300°C

|

572°F

|

|

Oval Gear Flow Meter

|

Fuel Oil, Lubricants, High Viscosity Fluids

|

200°C

|

392°F

|

|

Magnetic Flow Meter

|

Water, Wastewater, Slurries, Acids, Caustics

|

160°C

|

320°F

|

|

Liquid Turbine Flow Meter

|

Condensate,Refined Fuels, Solvents, Light Chemicals

|

150°C

|

302°F

|

|

Gas Turbine Flow Meter

|

Natural Gas ,N2,O2,CO2,air

|

80°C

|

176°F

|

Spotlight on Demanding High-Temperature Applications

Specialized flow meters from Silver Automation Instruments provide critical data in some of the world's most challenging industrial processes.

-

Superheated Steam and Condensate flow metering

Measuring steam flow is a classic high-temperature, high-pressure application found in power plants and industrial boilers. Vortex flow meters and differential pressure flow meters are the industry standard for this task, offering the durability and reliability needed to measure steam flow for energy management and process efficiency.

Heat transfer systems rely on the precise circulation of fluids like hot oil or pressurized hot water. Coriolis, Vortex, and Oval Gear meters are frequently used to monitor these closed-loop systems, ensuring correct energy transfer and process safety.

-

Asphalt, Bitumen, and Heavy Fuel Oil

These fluids present the dual challenge of extreme temperature and very high viscosity. They must be kept hot to remain fluid. High-temperature Coriolis mass flow meters and oval gear flow meters with heating jacket are the superior choice for measuring

asphalt (bitumen), providing accurate mass measurement for loading, blending, and combustion control.

-

Hot Air and Flue Gas Monitoring

-

-

Monitoring hot gases is critical for environmental compliance and process efficiency. This includes measuring the flow of combustion air to furnaces, hot exhaust air from dryers, and waste gases in flare systems. A primary application is flow measuring flue gas in stacks to monitor emissions. These tasks often involve dirty gas streams at high temperatures but low pressures. High-temperature thermal mass flow meters and Vortex flow meters are ideal for these applications, offering the robustness and direct measurement capabilities required.

One of the most extreme applications is the measurement of liquid metals like liquid lithium or liquid sodium, used as coolants in nuclear reactors and in advanced battery production. This requires highly specialized high-temperature Coriolis meters capable of withstanding high temperatures and the corrosive nature of molten metals.

Partner with the High-Temperature flow measurement Experts

Choosing the right flow meter for a high-temperature application is a complex decision that requires a deep understanding of the process and instrumentation technology. The team at Silver Automation Instruments has the expertise to help you navigate these challenges. We provide customized, high-performance flow sensors that deliver the accuracy and durability your process demands.

Contact our engineers today to discuss your high-temperature application and find the ideal measurement solution.

Thermal Mass Flow Meter2017/05/27Low cost gas flow meter.

Thermal Mass Flow Meter2017/05/27Low cost gas flow meter. Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Balanced Flow Meter2017/04/12Multi hole balanced flow meter is a kind of differential flow transmitters. It has obvious advantage over traditional orifice plate flow transmitters.VIEW

Balanced Flow Meter2017/04/12Multi hole balanced flow meter is a kind of differential flow transmitters. It has obvious advantage over traditional orifice plate flow transmitters.VIEW Vortex Flow Meter2017/04/12Vortex Flow meter is for clean liquid, gas and steam flow measurement. Contact us to choose proper type flow sensor and get the competitive quotation.VIEW

Vortex Flow Meter2017/04/12Vortex Flow meter is for clean liquid, gas and steam flow measurement. Contact us to choose proper type flow sensor and get the competitive quotation.VIEW Oval Gear Flowmeter2017/04/12Oval Gear Flow meter is for diesel, crude oil, resin, fuel, heavy oil flow measurement. PD flow meter is with mechanical register or digital display, Inquiry Price now.VIEW

Oval Gear Flowmeter2017/04/12Oval Gear Flow meter is for diesel, crude oil, resin, fuel, heavy oil flow measurement. PD flow meter is with mechanical register or digital display, Inquiry Price now.VIEW Liquid Turbine Flow Meter2017/04/12Liquid Turbine flow meter is a kind of low cost digital flow meter for diesel ,petrol,water,palm oil. it is for clean, low viscosity ,non-corrosive liquid.VIEW

Liquid Turbine Flow Meter2017/04/12Liquid Turbine flow meter is a kind of low cost digital flow meter for diesel ,petrol,water,palm oil. it is for clean, low viscosity ,non-corrosive liquid.VIEW