Inline oil flow meters measure the amount

of oil passing through the meter. Each flow meter does the same job but

achieves it by different methods. Oil flow measurements keep plants operating

safely and provide monitoring information over usage and production.

Oil comes in many forms, from thick lubrication

oil, viscous heavy oil, fuel oil, heating oil, engine oil, furnace oil to food

oils like sunflower and olive. An inline flow meter is installed into the

pipeline to provide measurements of volume and other factors.

Properties of Oil

The best flow meter depends on the type of oil and the conditions, as many factors will affect the way the oil flows through the pipe. These features include:

On-Site Use

The selection of the right flow meter will depend on the site, some flowmeters need a straight run of pipe feeding into and out of the meter and most do not work well at an angle. Ease of maintenance and access may make one flow meter a better choice compared with another for a site.

This mechanical flow meter consists of a

free-spinning turbine. The oil flowing through the pipe causes the turbine to

rotate. A sensor picks up the frequency of rotation and this converts to a

measurement of flow rate. The diameter of the pipe and the flow rate give a

volumetric measure per minute.

Pros:

Cons:

A vortex flowmeter uses the creation of vortices to measure oil flow.

Pros:

Cons:

Coriolis Flow Meter to be used as digital oil flow meter

A Coriolis flowmeter uses the degree of twist generated when the oil flows through a vibrating tube to measure mass flow,it is a kind of in-line oil mass flow

Pros:

Cons:

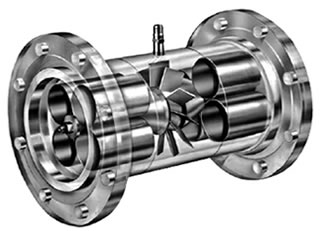

The oval gear flow meter operates on the positive displacement of the oil and is one of the most accurate flow meters.

Pros:

Cons:

A rotameter is a kind of variable area flow meter operates with a weighted float in a vertical tapered tube.

Pros:

Cons:

Liquid turbine flow meter with Hart Protocol2019/09/09TUF with HART and 4-20mA.

Liquid turbine flow meter with Hart Protocol2019/09/09TUF with HART and 4-20mA. SLW-N Liquid Turbine flow sensor2019/06/01Low cost turbine flow sensor.

SLW-N Liquid Turbine flow sensor2019/06/01Low cost turbine flow sensor. Oval gear flow meter with return to zero counter2019/07/09LC oval gear flow meter is equipped with mechanical counter which could also add with return-to-zero function. This kind of flow meter counter has 2 digits wheels, one for total flow totalizing; anoth...VIEW

Oval gear flow meter with return to zero counter2019/07/09LC oval gear flow meter is equipped with mechanical counter which could also add with return-to-zero function. This kind of flow meter counter has 2 digits wheels, one for total flow totalizing; anoth...VIEW Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW

Oval gear flow meter with pulser2019/07/09LC series oval gear flow meter with pulse output can have mechanical register also equip with a pulser to transfer pulse signals for other process control purpose. This gear driven flow meter is main...VIEW Coriolis mass flow meter2019/06/12Best accuracy flow meter

Coriolis mass flow meter2019/06/12Best accuracy flow meter Flanged Vortex flow meter2019/07/02STLU-1-B0 Series flanged Vortex flow meter is a volumetric flowmeter that measures the volumetric flow rate of a gas, steam or liquid, the principle of Karman vortex. It is mainly used for flow measur...VIEW

Flanged Vortex flow meter2019/07/02STLU-1-B0 Series flanged Vortex flow meter is a volumetric flowmeter that measures the volumetric flow rate of a gas, steam or liquid, the principle of Karman vortex. It is mainly used for flow measur...VIEW Wafer liquid turbine flow meter2019/08/07Wafer process connection.

Wafer liquid turbine flow meter2019/08/07Wafer process connection. Metal tube Rotameter2019/06/13Variable area flow meter

Metal tube Rotameter2019/06/13Variable area flow meter Soy bean oil flow meter2019/05/17It is suitable for soy oil metering in closed pipes; it has good wear resistance, high precision, robust construction and lowest price, we have stainless steel material for the oil flow sensor for foo...VIEW

Soy bean oil flow meter2019/05/17It is suitable for soy oil metering in closed pipes; it has good wear resistance, high precision, robust construction and lowest price, we have stainless steel material for the oil flow sensor for foo...VIEW Lube oil flow meter2019/08/15Oval gear flow meter is ideal solution for measuring lubricating oils flow rate. Oval gear flow meter is a kind of positive displacement flow meter for flow rate measurement of low and medium viscosit...VIEW

Lube oil flow meter2019/08/15Oval gear flow meter is ideal solution for measuring lubricating oils flow rate. Oval gear flow meter is a kind of positive displacement flow meter for flow rate measurement of low and medium viscosit...VIEW Palm oil flow meter2019/06/17We supply mechanical or electronic type palm oil flow meter at low price cost and good quality. Palm oil is a kind of edible oil, so the flow meter should be stainless steel material, and the process ...VIEW

Palm oil flow meter2019/06/17We supply mechanical or electronic type palm oil flow meter at low price cost and good quality. Palm oil is a kind of edible oil, so the flow meter should be stainless steel material, and the process ...VIEW Oil and Diesel Flow Meter2018/09/20Diesel flowmeter is a commonly used liquid flow measuring instrument, especially in high viscosity, dirty medium, easy to condense and easily block, high temperature, low temperature, strong corrosion...VIEW

Oil and Diesel Flow Meter2018/09/20Diesel flowmeter is a commonly used liquid flow measuring instrument, especially in high viscosity, dirty medium, easy to condense and easily block, high temperature, low temperature, strong corrosion...VIEW