The electromagnetic flow meter, often abbreviated as EMF or mag meter, is a high-performance instrument designed to measure the volumetric flow rate of conductive liquids,such as water, sewage, chemical ,acid and so on. It operates based on Faraday's Law of Electromagnetic Induction, a fundamental principle of physics.

Thanks to its unique design with no moving parts, the EMF offers significant advantages, including minimal pressure loss and the ability to accurately measure challenging fluids. It is the ideal choice for dirty, corrosive, or abrasive liquids and slurries. Consequently, it is widely trusted in industries such as chemical processing, metallurgy, mining, pulp and paper, and food and beverage. It also plays a vital role in monitoring municipal water distribution and wastewater treatment.

The Core Principle: Faraday's Law in Action

Faraday's Law states that when an electrical conductor moves through a magnetic field, a voltage (electromotive force or EMF) is induced across the conductor. The magnitude of this voltage is directly proportional to the velocity of the conductor, the length of the conductor, and the strength of the magnetic field.

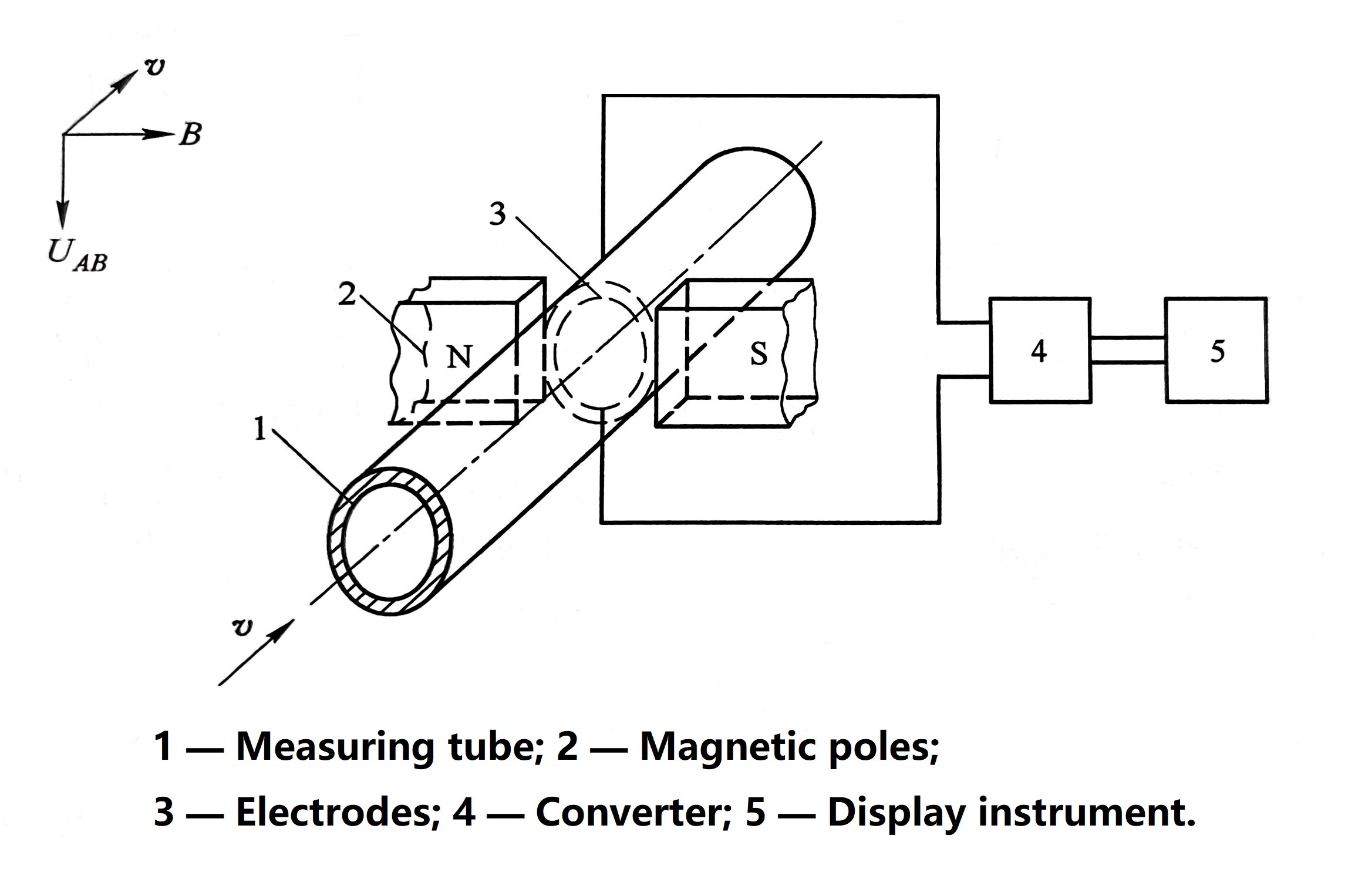

An electromagnetic flow meter applies this principle by treating the conductive liquid as the conductor. Here’s how it works:

Generating a Magnetic Field: The meter's body, known as the measurement tube, is equipped with coils that generate a controlled magnetic field perpendicular to the direction of flow.

The Liquid as a Conductor: As the conductive liquid flows through this magnetic field, it effectively "cuts" the magnetic flux lines.

Inducing a Voltage: This action induces a voltage that is directly proportional to the average velocity of the flowing liquid.

Measuring the Voltage: Two electrodes, mounted on opposite sides of the pipe wall, detect this induced voltage. A transmitter then processes this voltage signal to calculate the volumetric flow rate.

The relationship is described by the formula:

U = B * D * v

Where:

U = Induced Voltage (potential between electrodes)

B = Magnetic Field Strength (magnetic flux density)

D = Inner Diameter of the Measurement Tube

v = Average Flow Velocity of the Liquid

From this, the volumetric flow rate (Q) can be calculated. It's important to note that this principle relies on a uniform magnetic field, a conductive and non-magnetic fluid, and an axisymmetric flow profile.

Practical Considerations: The Finite-Length Magnetic Field

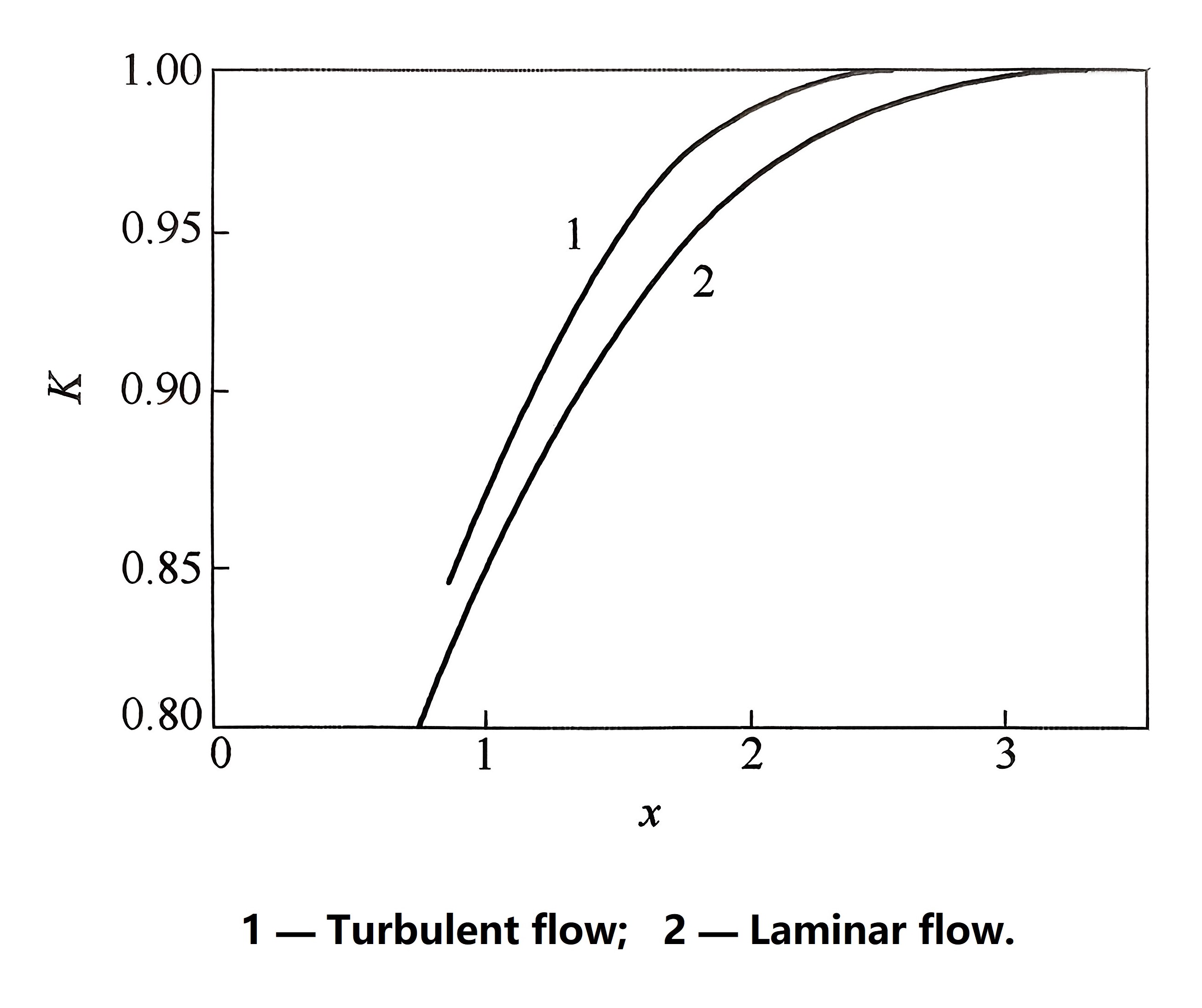

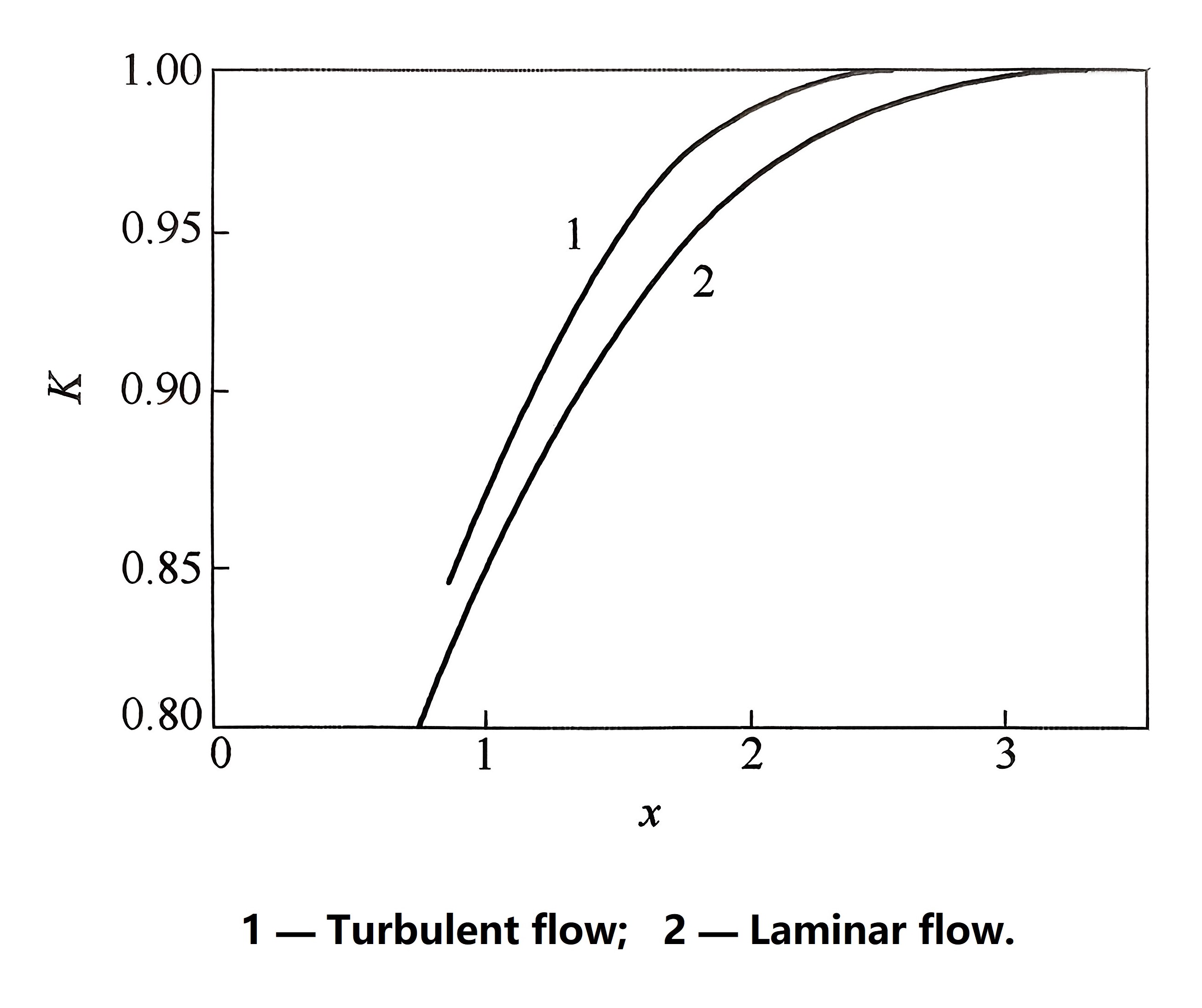

Limit magnetic filed correction factor curve

In a real-world application, the magnetic field cannot extend infinitely. It is strongest near the electrodes and weakens at the ends. This variation can create distortions known as eddy currents, which can affect measurement accuracy—a phenomenon called the edge effect.

To compensate for this, a correction factor (K) is applied, especially in pipes where the ratio of magnetic field length to pipe diameter is small. For most modern designs experiencing turbulent flow, the edge effect is negligible if this ratio is 2.5 or greater.

Excitation Methods: Powering the Magnetic Field

The excitation system is the heart of the meter, as it generates the magnetic field. The method used dictates signal processing and significantly impacts the meter's performance. There are three primary methods:

1. DC Excitation

This method uses permanent magnets or a DC power supply to create a constant magnetic field. While simple and immune to AC interference, DC excitation can cause electrolysis and electrode polarization in conductive fluids. This disrupts measurement and introduces errors. Therefore, DC excitation is typically reserved for measuring non-electrolytic liquids like liquid metals (e.g., sodium or mercury).

2. AC Excitation

Using a power-frequency (e.g., 50Hz) AC supply creates a sinusoidal magnetic field. This method avoids the polarization issues of DC excitation but introduces its own challenges:

Quadrature Interference: The alternating magnetic field can induce an unwanted "transformer effect" voltage in the electrode circuit, which can be much larger than the actual flow signal.

In-Phase Interference (Common-Mode): Noise signals that have the same phase as the flow signal can appear on both electrodes, often caused by stray currents or electrostatic induction.

Instability: Fluctuations in the AC power supply's voltage or frequency can alter the magnetic field strength, leading to measurement inaccuracies.

3. Low-Frequency Square Wave Excitation

This is the most advanced and widely used method today. It combines the benefits of both DC and AC approaches. By using a low-frequency square wave (e.g., 3-30Hz), it:

Eliminates polarization by constantly reversing the field.

Avoids quadrature interference by measuring the flow signal during the stable periods of the square wave.

Suppresses eddy currents, leading to excellent zero-point stability and high accuracy.

Modern advancements continue to refine this technique with innovations like tri-state and dual-frequency square wave excitation, further enhancing the performance and reliability of electromagnetic flow meters.