Water Hammer: Causes, Dangers & Prevention Solutions for Pipeline Safety

What Is Water Hammer?

Water hammer refers to the sudden increase or decrease in pressure resulting from the abrupt acceleration or deceleration of fluid flow inside a closed system. This hydraulic shock phenomenon creates powerful pressure waves that can exceed normal operating pressures.

When a valve closes quickly or a pump stops suddenly, the fluid moving at high speed is forced to stop, creating a pressure wave that travels back through the system. The force of this wave can lead to vibration, noise, or even structural failure.

Two Main Types of Water Hammer:

- Positive Water Hammer: Occurs when a valve closes rapidly or a pump stops suddenly, causing the water to hit against closed boundaries, producing a high-pressure shock wave.

- Negative Water Hammer: Happens when a closed valve is suddenly opened, creating a rapid drop in pressure. Although less severe, it can still cause flow instability and damage to components.

While most commonly observed in water pipelines, similar effects occur in steam systems, where it is often referred to as steam hammer.

Understanding the Dangers of Water Hammer

Critical Warning: Water hammer is not merely an operational inconvenience—it can be catastrophic for industrial systems if left unchecked. Pressure surges can reach levels exceeding 10 MPa (100 bar) in extreme cases.

Water hammer damage includes:

- Pipeline rupture or deformation - Especially at weak joints or welds

- Valve and pump damage - Due to high-impact forces on internal components

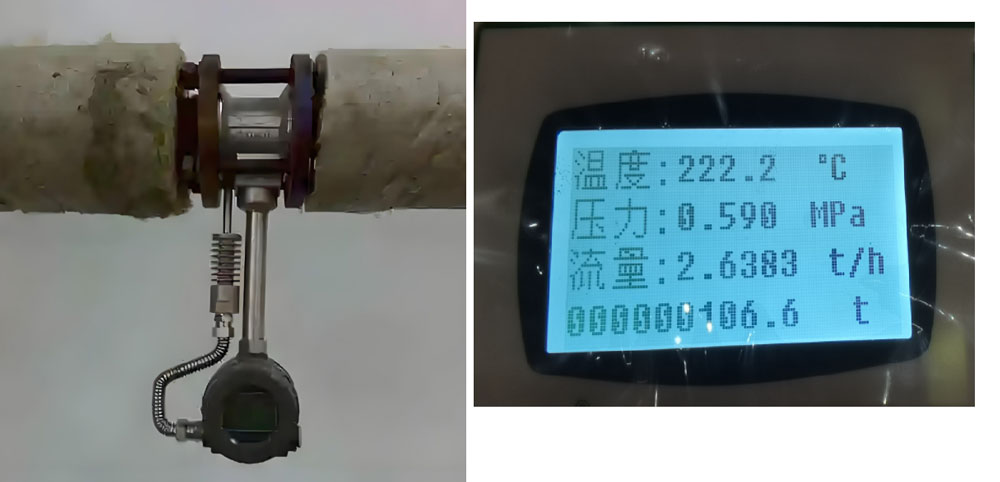

- Flow meter malfunction or destruction - Sensitive sensors cannot withstand sudden shock waves

- System vibration and noise - Metallic "bang bang bang" sounds along the pipe

- Equipment failure - Particularly in boiler systems, chemical process lines, and high-pressure pipelines

For plants relying on vortex flow meters, Coriolis mass flow meters, or electromagnetic flow meters, water hammer can severely distort readings or permanently damage the sensor body.

Root Causes of Water Hammer

Water hammer generally results from sudden changes in flow velocity. Understanding these causes is key to effective prevention:

(1) Rapid Valve Operation

When a valve is opened or closed too quickly, the fluid flow stops or starts abruptly, producing a shock wave through the pipe network. This is one of the most common causes of hydraulic shock.

(2) Sudden Pump Start or Stop

When a pump stops unexpectedly—due to a power failure, for instance—the fluid's momentum pushes back against the pump and valves, creating a large pressure spike.

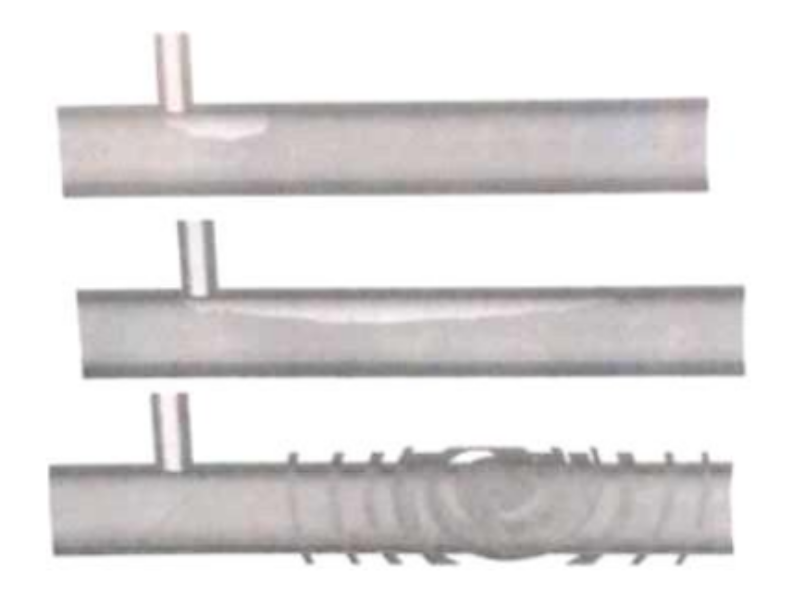

(3) High-Speed Condensate in Steam Lines

In steam systems, condensate can accumulate and move at high velocity. When this condensate collides with pipe walls or fittings, it generates a powerful water hammer, sometimes referred to as steam condensate hammer.

| High-speed condensate produces water hammer | The condensation of steam suddenly causes water hammer |

High-speed condensate creates water hammer when it collides with the pipe |

Water hammer occurs when steam condenses rapidly and collides |

(4) Pipe Design and Terrain

Pipelines with steep inclines or sudden elevation changes are more susceptible. When water is pumped to a height exceeding 20 meters, gravitational potential energy amplifies the surge pressure.

(5) Excessive Flow Velocity

If the flow velocity in the supply line is too high, even small disturbances can cause large dynamic pressure changes, increasing water hammer risk.

(6) Long and Complex Pipeline Systems

The longer the pipe and the greater the change in terrain, the more likely pressure waves will reflect and amplify, causing repetitive hammer effects.

Water Hammer Prevention Solutions

Eliminating water hammer completely is difficult, but several engineering measures can effectively mitigate or prevent its impact:

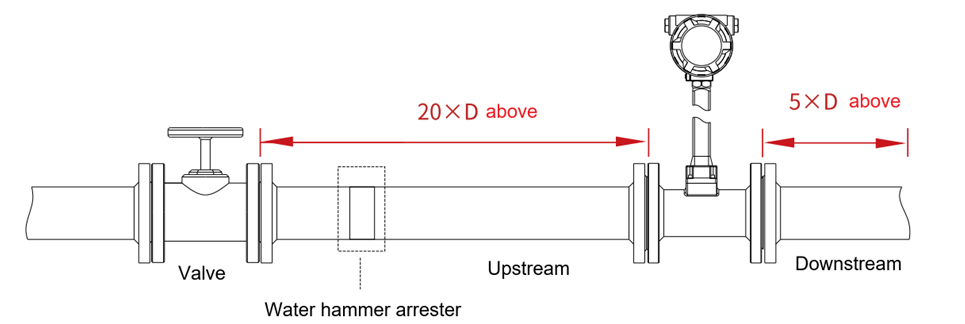

(1) Install a Water Hammer Arrestor

A water hammer arrestor or pressure surge tank absorbs excess energy from the pressure wave, converting it into kinetic energy of a cushioning gas or spring-loaded mechanism. These devices are highly effective in protecting flow meters and valves.

(2) Add an Accumulator or Air Chamber

In systems using piston or plunger pumps, an accumulator upstream of the flowmeter can dampen pulsations and stabilize flow.

(3) Use Controlled Valve Operation

Avoid quick valve movements. Utilize slow-opening and slow-closing valves or automated control valves with adjustable opening speeds to reduce the rate of flow change.

(4) Optimize Pump Control

Use soft-start controllers or variable frequency drives (VFDs) on pumps to gradually ramp up or slow down pump speed, minimizing sudden flow acceleration or deceleration.

(5) Proper Piping Layout

Design the pipeline with minimal elevation differences and avoid sharp bends where possible. Install the flowmeter at locations less susceptible to pressure fluctuations.

(6) Install Non-Return Valves

Check valves or non-return valves can prevent reverse flow and reduce the likelihood of back-pressure surges.

(7) Use High-Quality Flow Meters with Protection Features

Choose flow meters designed to withstand transient pressure surges. For example, Silver Automation Instruments offers vortex and Coriolis flow meters with robust stainless steel bodies and optional water hammer dampening accessories, ensuring longer service life in challenging hydraulic environments.

When to Install a Water Hammer Eliminator

It is recommended to install a water hammer eliminator or arrestor in the following situations:

- Valves are opened or closed rapidly

- Pumps are started or stopped suddenly

- Water is pumped to elevations exceeding 20 meters

- The pump's total head or operating pressure is large

- The flow rate in the supply line is very high

- The pipeline is long with significant terrain variations

Implementing these preventive measures ensures the long-term accuracy of flow meters, reduces maintenance costs, and protects valuable process equipment.

Conclusion: Protecting Your Pipeline from Water Hammer

Water hammer is a serious issue that can threaten the safety and reliability of any fluid transport system. By understanding its causes and implementing preventive solutions—such as installing water hammer arrestors, accumulators, and proper valve control—industries can significantly reduce the risk of equipment failure.

Protecting instruments like flow meters, pumps, and valves from hydraulic shock is not just a matter of maintenance; it's a critical step in maintaining system efficiency, measurement accuracy, and operational safety.

Need Reliable Flow Measurement Solutions?

Silver Automation Instruments provides durable flow meters and accessories designed to withstand demanding hydraulic conditions and protect against water hammer effects. Our solutions ensure long-term reliability in challenging industrial environments.

English

English  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  Türkçe

Türkçe  ไทย

ไทย  українська

українська  Malay

Malay  עברי

עברי  Indonesia

Indonesia  Ελλάδα

Ελλάδα  ಕನ್ನಡ

ಕನ್ನಡ  հայերեն

հայերեն

Email

Email

WA

WA

Inquiry

Inquiry