Why are low-temperature storage and hydrocarbon processing so difficult to handle?

Those who have worked in low-temperature storage and hydrocarbon processing know that this job is not easy to do. The temperature can drop as low as minus 100 degrees Celsius, and liquefied petroleum gas (LPG) is running through the pipeline. A slight mistake could result in a major accident. It is not an easy task for a flowmeter to accurately measure under such extreme cryogenic conditions.

Cryogenic

storage and hydrocarbon processing industry

The current gas processing plants and low-temperature storage tanks rely entirely on these cryogenic flow meters to ensure safe operation, accurate handover, and process control. Choosing the right instrument saves time and effort; Wrong choice, trouble keeps coming.

Three main media, each with its own temperament

Liquid ethane is the most difficult liquid to measure.

Ethane cryogenic

flow meter

Ethane, when in liquid form, can cool to -116 ° C, with a density fluctuating between 552-568 kg/m3 and viscosity changing accordingly. What's even more troublesome is that it can be liquid at times and gas at other times, with pressures ranging from 3.5 to 29 kilograms of force. Petrochemical plants use it as raw material to produce ethylene, so flow measurements cannot be taken lightly.

Liquid Propane flow measurement is relatively better, but it's not simple either

Propane Flow

Meter

The working temperature of liquid propane is between -50 ° C and 40 ° C, which is milder than ethane. Density 581-585 kg/m3, viscosity 0.19-0.21 cp, looks quite stable. But the problem is that the flow rate varies greatly, ranging from very small to over 30000 kilograms per hour , which requires the range ratio of the flowmeter to be wide enough. The design pressure can reach 35 kilograms of force, and the material must also be able to withstand it.

Large pipes are a problem for hydrocarbon gases

Hydrocarbon

Gas flow meter

The gas measurement in the torch system uses pipes that are as big as 24 inches or 36 inches. The molecular weight of the gas is around 21:00, the compression coefficient is 0.9887, and the flow rate ranges from 0.1 million standard cubic meters to 330 million standard cubic meters per day. The temperature is not extreme, it's around 30-40 degrees, and the pressure is only 6-8 kilograms of force.

Two mainstream flow meters, each with its own advantages

Coriolis flowmeter - expensive but useful for liquid propane and ethane

When it comes to measuring liquid ethane and propane, the Coriolis flowmeter is the most reliable. It directly measures mass flow without worrying about density changes, with an accuracy of ± 0.05% or even higher, making it the most suitable for custody transfer. When loading and unloading materials, both sides can be measured, which is particularly practical.

Why do instruments engineers prefer to use it?

-No matter how the density of the liquid propane or ethane changes, the measured mass flow is always accurate and direct

-Large range ratio, good accuracy from small flow rate to large flow rate

-One flow sensor can measure density, temperature, and viscosity, saving several sensors.

-There are no moving parts, so there is basically no need for maintenance

-Cryogenic flow meter has stable work even at temperatures below minus 100 degrees Celsius

It can hold anything from 3/8 inch to 10 inch tubes, with a liquid volume of 800 to 2000 cubic meters per hour and a gas volume of over 60000 kilograms per hour.

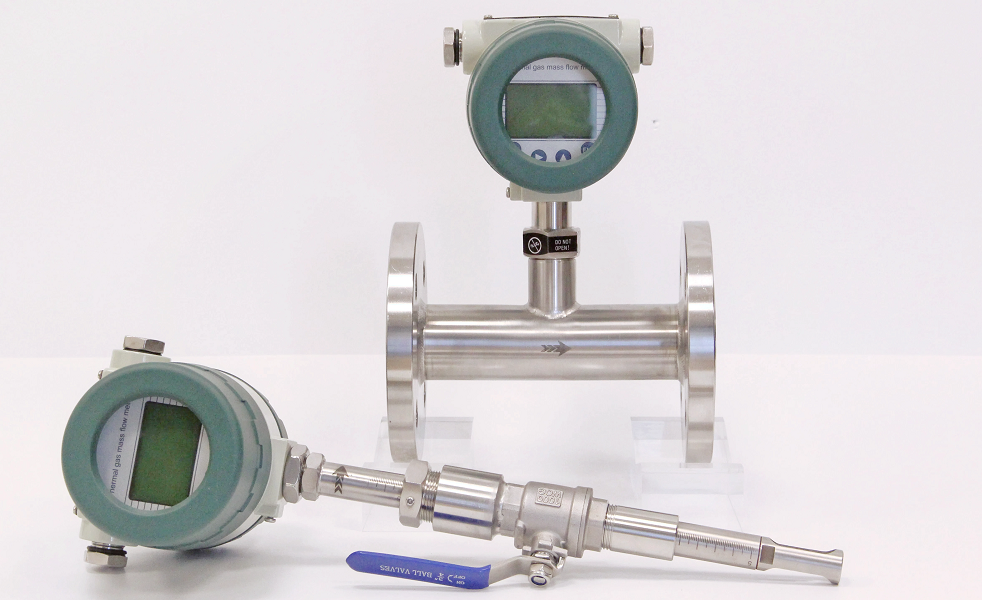

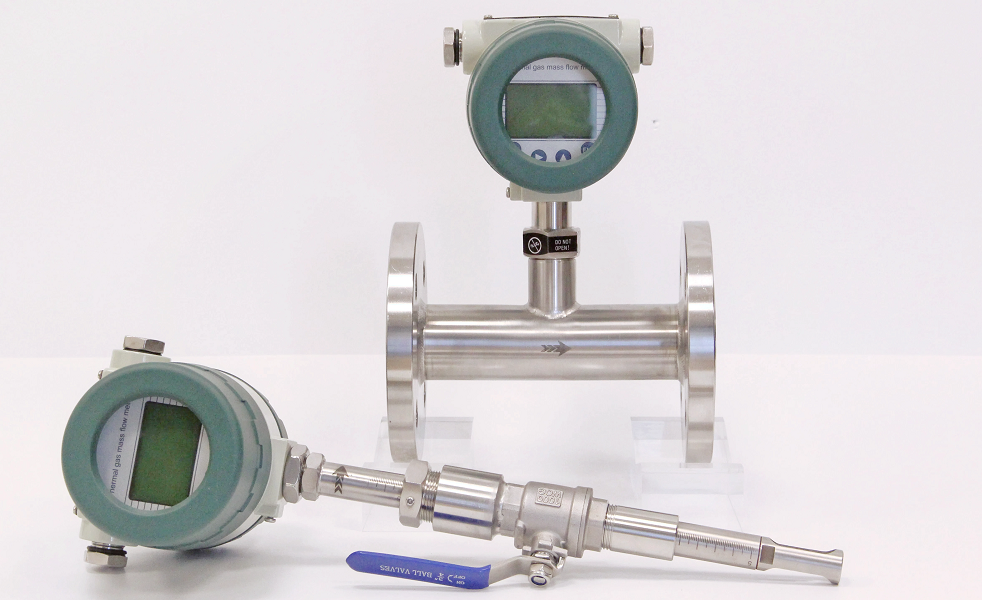

Thermal mass flow meter

Thermal mass flowmeter - an economical choice for large pipelines

Thermal flow meters are the most cost-effective for measuring gases, especially gases in large pipes. The insertion installation is convenient and has almost zero pressure loss, which is particularly important for low-pressure torch systems. Its principle is to use a heated probe to measure the heat dissipation speed to calculate the flow rate, and directly output the mass flow rate without the need for pressure and temperature compensation.

What are its benefits when using thermal mass flow meters for hydrocarbon

-Direct measurement of gas quality, saving time

-Even low flow rates can be accurately measured

-It can be measured from 0.1 million standard cubic meters per day to several hundred million standard cubic meters

-It's cheap to install and easy to maintain

-Can interface with DCS system using HART protocol

-It can also display molecular weight in real-time, which is quite useful

A thermal flowmeter is most suitable for places close to atmospheric pressure, such as torch separation tanks.

Pay attention to these points when choosing a flow meter

Pressure and temperature should not only depend on working conditions

Don't just look at the temperature and pressure during normal operation; you have to consider the design limit. Although the liquid ethane flowmeter operates at -116 ° C, it is designed to withstand a pressure of 43.5 kilograms from -118 ° C to 65 ° C. Liquid propane is also used, ranging from -52 ° C to 115 ° C, with a force of 35.7 kilograms. The material must be selected correctly and should not be brittle at low temperatures.

ATEX flow meters are often needed

This situation is a Zone 1 hazardous area, with gas group IIA and temperature group T3. The flow meter must have ATEX certification and explosion-proof level Ex'd '. The protection level IP 67 is also required; otherwise it will eventually be damaged by water and dust.

The signal output from flow meter should be able to dock

Now they are all connected to DCS systems, and the HART protocol is standard. By adding a 4-20mA analog signal and a HART digital signal or MODBUS RTU, parameters can be set and diagnostic information can be viewed remotely. Advanced digital flow meters or analog low temperature flow meter can transmit multiple data simultaneously, including flow rate, density, temperature, and cumulative measurement, making it easy to control.

Several Considerations for Installing

Don't just focus on the maximum flow when choosing a proper flowmeter

Many engineers list rely solely on whether the maximum flow is sufficient, which is not correct. It depends on three points: minimum flow rate, normal flow rate, and maximum flow rate. Coriolis flowmeters are generally most accurate within the range of 20% to 100%, while thermal flowmeters have a wider range. Only when all three flow points are within the accuracy range, can this table be considered selected correctly.

Pressure drop cannot be ignored

Especially in gravity flow or low-pressure systems, the pressure drop is very lethal. The Coriolis flowmeter can drop up to 0.3 kilograms of force, while the thermal type hardly drops pressure. Once the calculations are done, choose again, otherwise the liquid will easily vaporize, the downstream pressure will be insufficient, and the entire system will be in chaos.

Calibration certificates must be complete

Accuracy must be ensured, and regular calibration is essential. Coriolis flowmeters are usually calibrated with water or light hydrocarbons before leaving the factory, and a calibration certificate will be provided, which includes testing conditions, pressure records, and range verification. For trade handover, this certificate must be present and traceable.

To summarize

Choosing flow meters for liquid ethane, liquid propane, and hydrocarbon gases requires a clear understanding of process conditions, fluid properties, and actual requirements.

Liquid trade handover, although the Coriolis flowmeter is expensive, it has high accuracy, is worry free, and you get what you pay for. For gas measurement with large pipes, thermal flow meters are the most cost-effective, with low pressure drop and cheap installation and maintenance.

The low-temperature and hydrocarbon processing industry is characterized by extreme temperatures, large pressure changes, and a wide flow range. Without reliable flow meters, it is really not feasible. The watch selection is correct, the measurement is accurate, meets the specifications, and the system is stable, saving a lot of money compared to the price difference of the watch.

FAQ

Q1: Do you still need a low-temperature Coriolis flowmeter to measure propane at room temperature? Is it too expensive?

Answer: It really needs to be used. Although it is at room temperature, the density of propane still varies with temperature. The Coriolis flowmeter directly measures mass without affecting density, with an accuracy of ± 0.05%. This accuracy is required for handover. And it can measure density and temperature on its own, saving the cost of buying another meter. After calculation, it's actually not a loss.

Q2: What meter is used to measure gas in a 24 inch ambient temperature torch pipeline? Orifice plates are cheap, why not use them?

Answer: Thermal mass thermal flow meters are the most suitable. It is cost-effective to use it for large pipes, as it can directly measure mass flow without pressure and temperature compensation. The key is that it hardly drops pressure, and the torch system is already under low pressure and cannot drop. Although orifice plates are cheap, the permanent pressure loss is too great, and low-voltage systems cannot be used at all.

Q3: What is the use of the "real-time molecular weight display" in the thermal flowmeter?

Answer: This function is quite practical. Flow meters can sense changes in gas molecular weight, and a change in molecular weight indicates a change in gas composition. If there are problems with the process or changes in the feed, it can detect them in advance, which is equivalent to having multiple monitoring methods. The operator looked at this number with confidence.

Q: Do you have a cheaper option than Coriolis for room temperature liquids that do not require particularly high precision?

Answer: Yes, vortex gauges, turbine gauges, and elliptical gear gauges are all cheaper than it. But these meters measure volumetric flow rate, and to calculate mass, high-precision density meters, thermometers, and a flow integrator are needed. The system has become more complex and there are more sources of error. If there is no shortage of money, it would be more convenient for Coriolis.