Installing a pressure

transmitter correctly is critical to ensure reliable, stable, and accurate

pressure, differential pressure, or liquid level measurements in any industrial

process.

This detailed guide from Silver Automation Instruments provides

step-by-step instructions and best practices for electrical installation, mechanical mounting, impulse line layout, and remote diaphragm

seal configuration.

Whether you are setting up a differential pressure transmitter, gauge

pressure transmitter, or level transmitter, proper installation guarantees

measurement precision, device longevity, and safe operation under demanding

industrial conditions.

1.

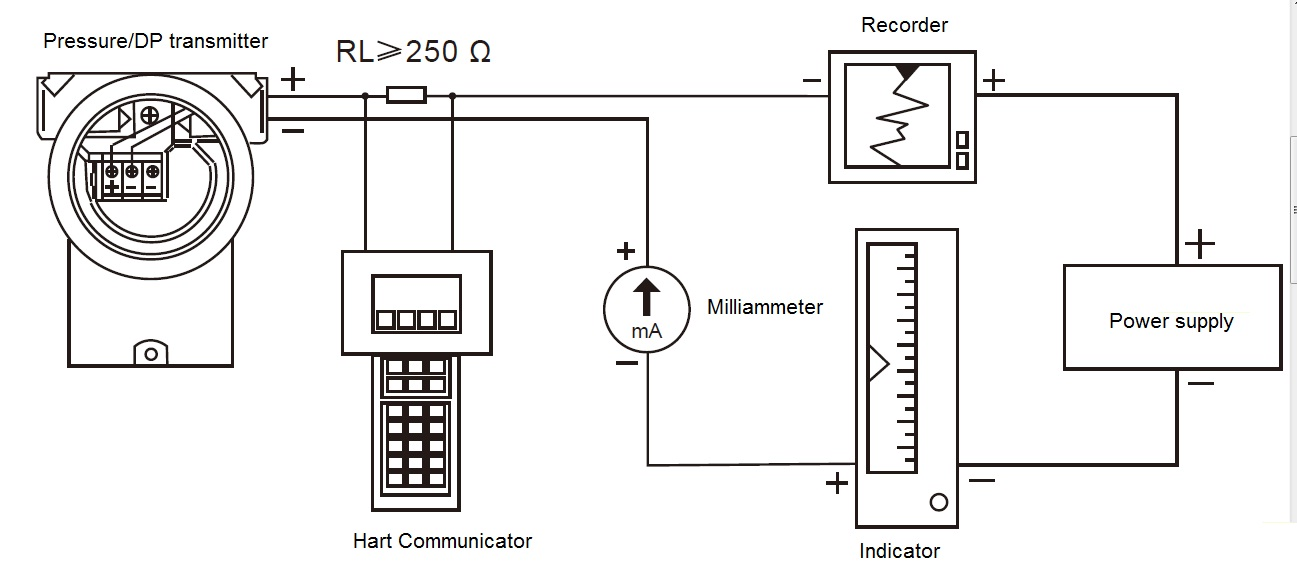

Electrical Installation and Wiring of Pressure Transmitters

Termincal of DP transmitter

Electrical wiring is the

foundation for stable signal transmission. The power supply wire and signal

wire share the same cable, simplifying installation and reducing potential

wiring errors.

To begin, remove the housing

cover on the terminal compartment side and connect the positive and negative

leads to the corresponding terminals. Silver Automation Instruments

recommends using a twisted-pair or shielded cable to minimize

electromagnetic interference (EMI) and ensure signal stability, especially in

environments with heavy electrical noise such as refineries, chemical plants,

or power generation facilities.

-

Recommended wire

cross-section: 0.5 mm² ≤ S ≤ 2.5 mm²

-

Shielding and grounding: Always ground the shielding properly to avoid signal drift.

-

Moisture protection: Plug and seal any unused conduit entry to prevent moisture accumulation inside the terminal compartment.

-

Conduit separation: Do not run the signal cable in the same conduit as high-voltage power

lines.

If the conduit cannot be

sealed, it should face downward (“adown”) to prevent condensation buildup

inside the transmitter enclosure.

Proper electrical installation

ensures that your pressure transmitter output (4–20mA, pulse, or digital

HART/Modbus signal) remains stable and accurate throughout the operating

life of the device.

DP Transmitter wiring

2.

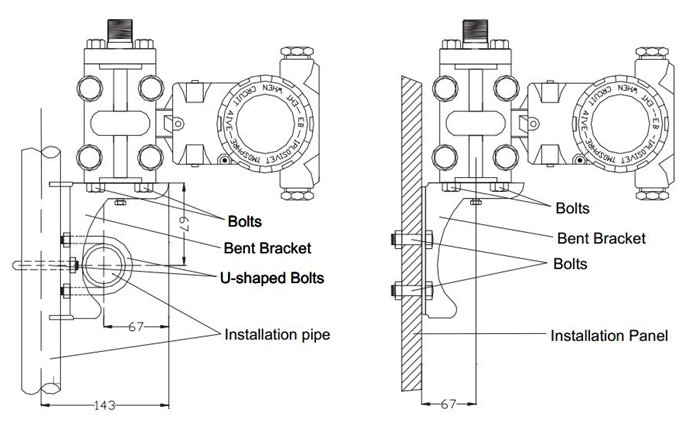

Mechanical Installation and Mounting Methods

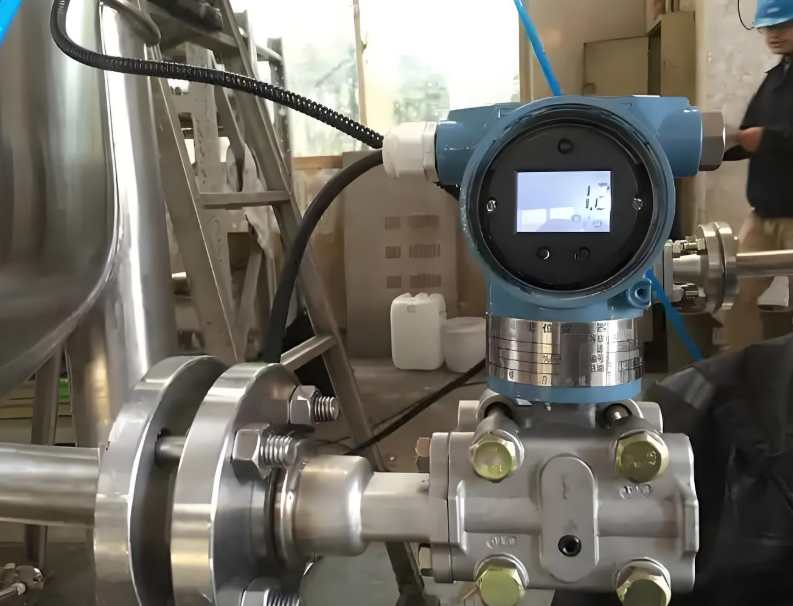

Diaphragm Seal DP Transmitter install

Pressure transmitters can be

mounted directly on process taps or remotely using brackets and impulse

lines. Silver Automation Instruments offers several mounting

configurations, including:

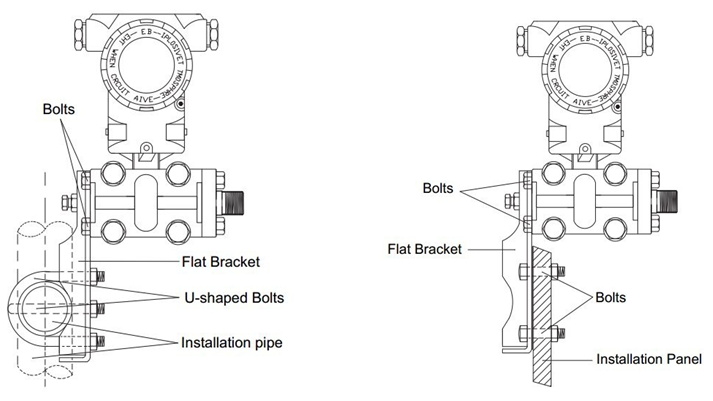

-

Bent bracket pipe mounting

-

Bent bracket panel mounting

-

Flat bracket pipe mounting

-

Flat bracket panel mounting

Bent Bracket Pipe Mounting Bent Bracket Panel Mounting

Flat Bracket Pipe Mounting Flat Bracket Panel Mounting

These configurations allow

flexible installation depending on plant layout and accessibility.

2.1

Process Connection and Mounting Tips

The process connection of most

transmitters is ¼ NPT on the flange, with adaptors available for ½

NPT taper threads.

When connecting impulse lines, tighten bolts incrementally in a cross

pattern to avoid distortion, using a maximum torque of 40 N·m.

Key mechanical

recommendations:

-

Keep impulse piping as short

and straight as possible.

-

Avoid sudden temperature

fluctuations, vibration, or corrosive atmospheres.

-

Mount the pressure

capsule vertically to prevent zero shift.

-

For differential pressure

transmitters measuring vertical pipelines, compensate for height

difference using “zero pressure trim” through the display or HART

communicator.

Proper mounting of the pressure

transmitter and impulse lines directly affects measurement accuracy and

repeatability.

3.

Impulse Line Installation and Error Prevention

Impulse lines transfer

pressure from the process taps to the transmitter. Incorrect impulse line

design or installation can cause measurement drift or systematic errors.

Common

Causes of Measurement Errors

-

Leakage or loose fittings

-

Erosion or abrasion due to

purge gas or liquid

-

Gas bubbles in liquid lines

or liquid slugs in gas lines

-

Unequal temperature across

both impulse legs

-

Incorrect slope causing

trapped gas or condensate

Best

Practices to Minimize Error

-

Keep impulse piping short

and equal in length.

-

For liquid service,

slope the impulse piping upward (≥1/12) from transmitter to

process.

-

For gas service,

slope it downward (≥1/12) from transmitter to process.

-

Vent gas from liquid legs

and drain condensate from gas legs.

-

Use large-diameter tubing to prevent friction loss and blockage.

-

When purging, connect purge

lines near the process taps and purge through equal-length pipes—never

purge through the transmitter.

-

Maintain both impulse lines

at similar temperature to prevent density differences.

These guidelines are essential

for reliable differential pressure measurement and long-term transmitter

stability.

4.

Remote Diaphragm Seal Installation Guidelines

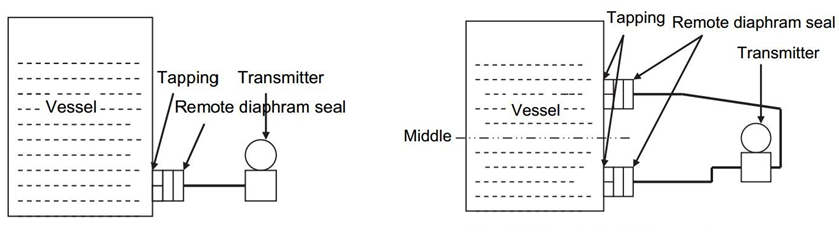

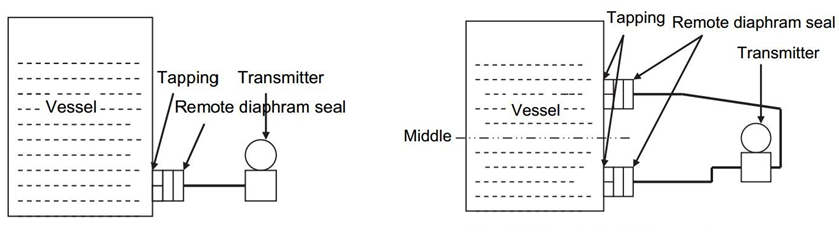

In applications involving high

viscosity, high temperature, or corrosive media, remote

diaphragm seal transmitters are used to isolate the sensing element from

the process fluid.

Best

Installation Practices

-

Keep capillaries as short

as possible to reduce response time.

-

Avoid direct sunlight or heat sources to prevent temperature-induced drift.

-

Ensure both capillaries are equal

in length when using dual remote seals.

-

Mount transmitters with one

diaphragm seal at or below the process connection level.

-

For two remote seals,

install the transmitter between or slightly below both seals.

Remote Diaphragm Seal pressure transmitter Installation

Correct capillary routing and

equal seal lengths ensure stable readings and accurate pressure or level

measurement in reactors, tanks, and pipelines.

5.

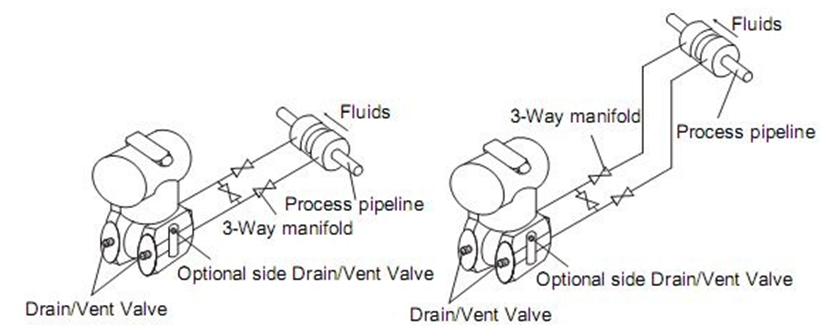

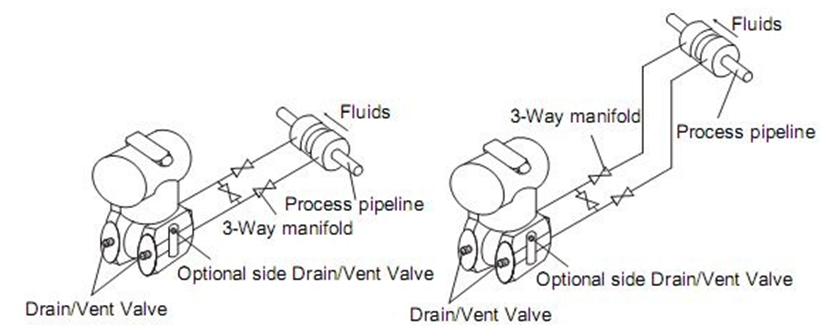

Liquid, Gas, and Steam Flow Measurement

Different media require

specific installation orientations to ensure accuracy and prevent trapped

phases.

5.1

Liquid Flow Measurement

Liquid Flow Measurement

-

Place taps on the side of

the line to prevent sediment accumulation.

-

Mount the transmitter beside

or below the taps so gases can vent into the process.

-

Keep the drain/vent valve

facing upward to allow gas release.

5.2

Gas Flow Measurement

-

Mount taps on the top or

side of the pipeline.

-

Install the transmitter above the taps to allow liquids to drain back into the line.

5.3

Steam Flow Measurement

-

Install taps on the side

of the line, and mount the transmitter below the taps to keep

the impulse lines filled with condensate.

-

For steam above 250°F

(121°C), fill impulse lines with water to protect the sensor and

maintain measurement accuracy.

-

Ensure the process

temperature does not exceed the transmitter’s rated limit.

These guidelines guarantee

accurate flow readings across different media and operating conditions.

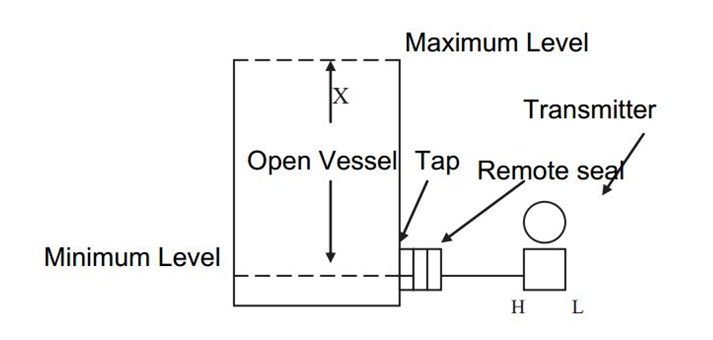

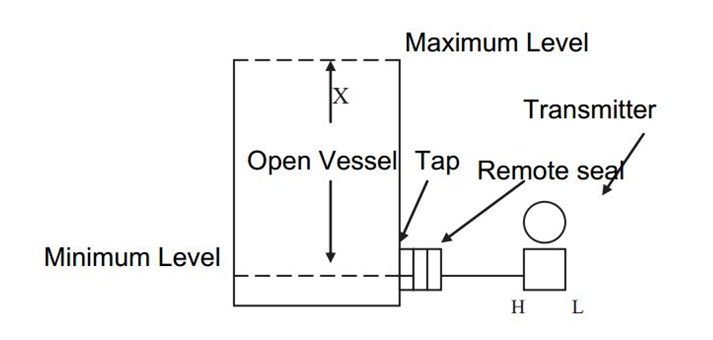

6. Level

Measurement Using Pressure Transmitters

Pressure transmitters can also

be used to measure liquid level in open or closed vessels by detecting

the hydrostatic pressure of the liquid column.

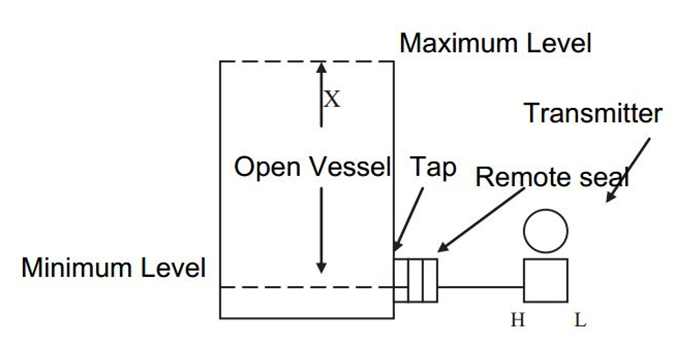

6.1

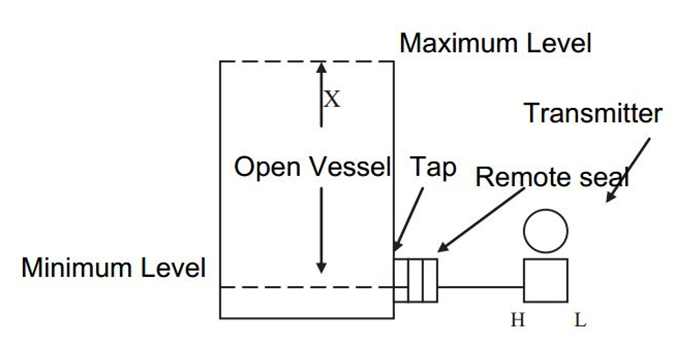

Open Vessels

Connect the transmitter’s high-pressure

side to the bottom tap, with the low-pressure side vented to the

atmosphere.

If the transmitter and tap are on the same level:

Transmitter with the same level as tap

Px=x×ρ×g

where x = liquid height

(m), ρ = fluid density (kg/m³), g = 9.80665 m/s².

Example: For x = 6.5 m and ρ = 1000 kg/m³,

Range = 0 ~ 63.7 kPa.

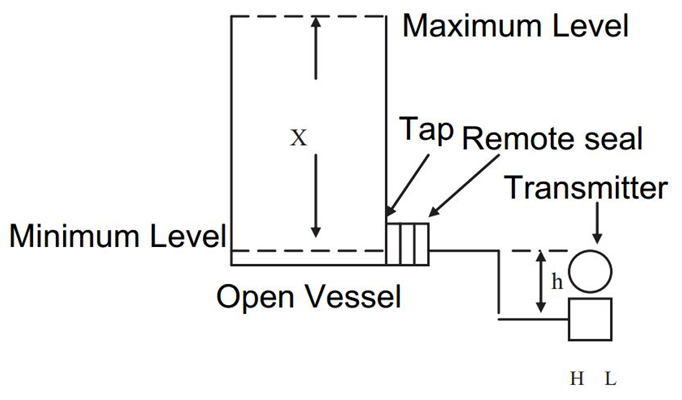

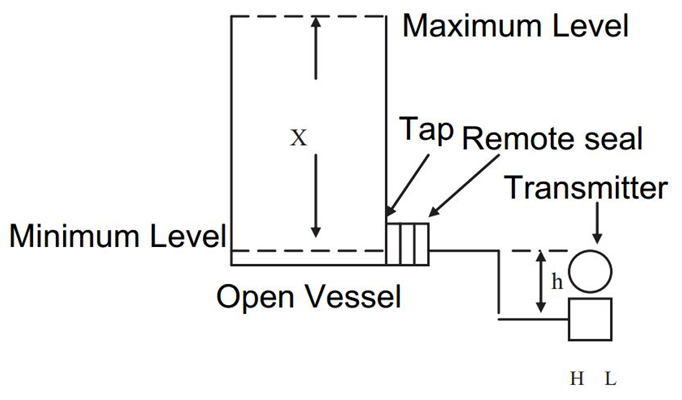

If the transmitter is higher

or lower than the tap, additional terms (±hρ₀g)

must be included to correct for height differences and fill fluid density (ρ₀).

Transmitter with higer level than Tap

Transmitter with lower level than Tap

6.2

Closed Vessels

In closed tanks, the

transmitter must compensate for vapor or gas pressure above the liquid.

Two main methods are used:

-

Dry leg condition: Gas above liquid does not condense; the low-pressure side remains empty.

-

Wet leg condition: Both sides are filled with liquid using double remote seals to

prevent condensation errors.

Example calculation (wet leg):

Range=g(yρ−hρ0) g[(x+y)ρ−hρ0]

This ensures the differential

pressure reflects only the actual liquid level, not vessel pressure variations.

⚠️ Attention: The process

medium should not freeze, or it may damage the isolation diaphragm or

transmitter module.

Transmitter and DP transmitter install

7.

Environmental and Safety Considerations

-

Avoid installing

transmitters in areas with strong vibration, extreme temperature

change, or direct sunlight.

-

Use heating jackets for viscous or heavy oils.

-

For explosion-proof models,

ensure compliance with hazardous area certification (ATEX / Exd).

-

Always depressurize and vent

lines before maintenance or calibration.

Following these safety and

environmental recommendations ensures long-term reliability and compliance with

industrial standards.

8.

Troubleshooting Common Installation Problems

|

Problem

|

Likely

Cause

|

Recommended

Solution

|

|

Unstable

reading

|

Gas

in liquid line / poor grounding

|

Vent

trapped air, check shielding

|

|

Zero

shift

|

Horizontal

capsule position

|

Rotate

housing, perform zero trim

|

|

Slow

response

|

Long

or unequal capillaries

|

Shorten

and equalize lines

|

|

Drifting

signal

|

Moisture

ingress

|

Seal

conduits and dry connections

|

|

Incorrect

level reading

|

Temperature

difference in legs

|

Use

equal-length impulse lines

|

Proper preventive maintenance

and installation checks can eliminate most issues encountered during field

commissioning.

9. Why

Choose Silver Automation Instruments

Silver Automation Instruments is a

trusted pressure transmitter manufacturer in China, serving global

customers across industries such as oil & gas, power generation, water

treatment, and chemical processing.

We provide:

-

Differential, gauge, and

absolute pressure transmitters

-

Models with remote

diaphragm seals, HART/Modbus output, and explosion-proof

housing

-

Factory calibration and full

ISO 9001 compliance

-

Custom process connections

and materials for corrosive applications

Visit our website www.silverinstruments.com to

explore our full range of industrial automation instruments, including Coriolis

mass flow meters, magnetic flow meters, and positive displacement

flow meters.

Conclusion

Proper pressure transmitter

installation and wiring is vital for obtaining accurate process data and

maintaining plant efficiency.

By following the electrical, mechanical, and calibration recommendations

provided by Silver Automation Instruments, you can ensure your

transmitter performs reliably under all conditions — whether measuring steam

flow, tank level, or process pressure.

With careful attention to

details like impulse line routing, capillary placement, and environmental

protection, your transmitter will deliver years of precise,

maintenance-free service.

FAQs: Pressure Transmitter Installation, Wiring & Calibration

1) What cable should I use for a 4–20 mA/HART pressure transmitter?

Use twisted-pair, shielded cable (0.5–2.5 mm²). Ground the shield at one end only (typically the control room) to reduce ground loops and EMI.

2) Can I route the transmitter signal cable in the same conduit as power lines?

No. Run low-level signal wiring in a separate conduit. If a conduit entry can’t be sealed, orient it downward to prevent moisture ingress.

3) How do I prevent moisture from causing drift or intermittent signals?

Seal unused entries, use proper cable glands, add a drip loop, and consider a desiccant pack in humid areas. Inspect periodically for condensation.

4) What straight-run and mounting orientation help minimize zero shift?

Mount the capsule vertical when possible. For DP applications, keep impulse lines short, equal in length, and correctly sloped (liquid: up toward process; gas: down toward process).

5) When should I choose a wet leg vs. a dry leg for closed vessels?

Dry leg: Vapor space is non-condensing (stays dry).

Wet leg: Vapor condenses or temperatures vary; fill both legs (or use dual remote seals) to keep densities stable and avoid level errors.

6) How do I size capillaries for remote diaphragm seals?

Keep them as short as practical, protected from heat/sun, and equal length for dual seals. Shorter and equal capillaries improve response and reduce temperature-induced drift.

7) What torque should I apply to process connections and flanges?

Tighten bolts gradually with a cross pattern; maximum typical torque is 40 N·m for the listed assemblies (verify with your specific model and gasket material).

8) How do I zero and range a DP transmitter after installation?

Isolate the process, equalize both sides (open equalizing valve), perform zero trim from the display or HART/Field communicator, then apply a known pressure (hand pump or deadweight) to set span.

9) What are common causes of unstable readings and how do I fix them?

Air in liquid legs, liquid slugs in gas legs, loose fittings, poor shielding/grounding, and temperature differences between impulse lines. Vent/drain legs, tighten fittings, and equalize line lengths and temperatures.

10) How should I install taps for liquid, gas, and steam flow measurement?

Liquid: taps on the side; transmitter at/below taps so gases vent to process.

Gas: taps on top/side; transmitter above taps so liquids drain back.

Steam: taps on the side; transmitter below taps; fill legs with water above 121 °C to protect the sensor.

11) What safety and certification points matter in hazardous areas?

Use transmitters with appropriate approvals (e.g.,

ATEX/IECEx Ex d/Ex ia). Ensure proper barriers, grounding, and installation per the zone classification and local code.

12) How do I calculate the range for level measurement in open tanks?

Range ≈ ρ·g·H (e.g., 1000 kg/m³ × 9.80665 m/s² × height). If the transmitter is not at the same elevation as the bottom tap, include head corrections from elevation differences and any fill fluid.

13) Why is my response time slow on a remote seal system?

Excessive capillary length, small bore, or temperature gradients increase fill-fluid viscosity and response time. Shorten/equalize capillaries and insulate from heat sources.

14) How often should a pressure transmitter be calibrated?

Typical plant practice is 6–12 months. Calibrate sooner after first startup, after maintenance, or when process or ambient conditions change significantly.

15) What’s the best way to purge impulse lines without damaging the transmitter?

Introduce purge near the process taps and purge through equal-length tubing back to process or a safe drain—never purge through the transmitter body.

Author: Silver Automation Instruments — Engineering Team

Practical instrumentation specialists with 10+ years of field experience in flow, pressure, and level measurement.

Expertise in Pressure, gas turbine, Coriolis, magnetic, and ultrasonic meters. ISO 9001 processes.

Website: silverinstruments.com |

Email: technician@silverinstruments.com

Differential Pressure Transmitters2018/01/04Monocrystalline silicion sensor;

Differential Pressure Transmitters2018/01/04Monocrystalline silicion sensor;  SH 308 Series Pressure Transmitter2017/04/26Piezoresistive pressure cost is low;

SH 308 Series Pressure Transmitter2017/04/26Piezoresistive pressure cost is low;  Pressure Transmitter with Remote Diaphragm seals2017/04/12Remote diaphragm for corrosive or viscous fluids.

Pressure Transmitter with Remote Diaphragm seals2017/04/12Remote diaphragm for corrosive or viscous fluids. Remote seal pressure transmitter2020/05/29You probably looked for this articlebecause there is so much you need to understand about a remote seal pressuretransmitter in detail, which is, in some instances, referred to as a chemical ora diaphr...VIEW

Remote seal pressure transmitter2020/05/29You probably looked for this articlebecause there is so much you need to understand about a remote seal pressuretransmitter in detail, which is, in some instances, referred to as a chemical ora diaphr...VIEW Ceramic Pressure Sensor2025/04/02Ceramic capacitive pressure sensor.

Ceramic Pressure Sensor2025/04/02Ceramic capacitive pressure sensor.