Systems of pressure measurement

The force applied to a specific area can be described with the term pressure. There is a variety of systems that can measure pressure, but the most widely known are the absolute and gauge pressure. Those measurements have quite a lot of differences that can affect a lot both their use and measurement. When it comes to measuring pressure, particularly lower pressure, it is vital that you choose wisely between those two types . Choosing properly is as vital as selecting the pressure range itself. A bad choice can lead to serious problems and errors to your final measurement,you will enconter the problem when you select proper type

pressure gauge or pressure transmitters.

Difference in the zero point

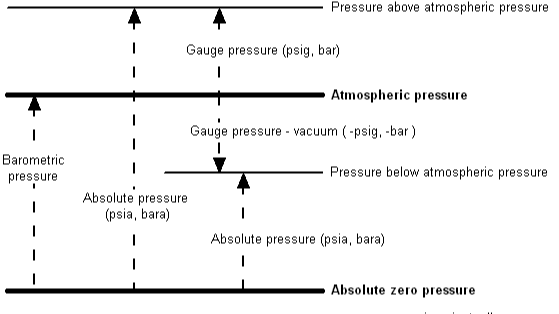

The main difference between the two types of measurement is their zero point. Absolute pressure has the absolute zero as the zero point. On the other hand, gauge pressure has atmospheric pressure as the zero point. The fact that atmospheric pressure can vary a lot leads to a lower precision when compared to the absolute pressure.

Gauge pressure characteristics

Gauge pressure, referred to with the letter g after the unit (30 psig.), is always measured according to atmospheric pressure. That practically means that any changes in atmospheric pressure due to altitude or different weather conditions, affects the measurement of a gauge pressure sensor directly. When the gauge pressure is higher than the ambient pressure, then we talk about a positive pressure. The exact opposite is referred to as a negative or vacuum pressure.

Vented gauge pressure sensors

The sensors used to

measure gauge pressure have one pressure port. With the help of a vent hole or a tube, the atmospheric air pressure moves through them to the sensing element at the back of the hole or the tube. The existence of a gauge vented transmitter enables the air pressure from the outside to get exposed to a special side of a sensing diaphragm, called the negative side. That process enables the gauge sensor to always measure having as zero point the atmospheric pressure.

Sealed gauge pressure

A sealed gauge pressure is actually the pressure that is measured with the use of a gauge sensor through a sealed device and when the zero point is previously set. The manufacturer of the gauge sensor decides on the set before the device is sealed. So, although sealed pressure is quite similar to the vented pressure, there is a major difference. Here, atmospheric pressure is sealed on the side of the diaphragm, known as the negative one. These sensors are usually used in applications where high pressure, like hydraulic pressure is adopted.

Absolute reference pressure

The absolute pressure can be found inside a perfect vacuum or a space, where the absolute zero is considered as the reference point. The measurement of barometric pressure is a good example of how absolute pressure is applied in everyday life. The manufacturer who is going to make an absolute pressure sensor, needs to seal a high vacuum. The vacuum should be sealed just behind the sensing diaphragm. This means that should you hold the pressure connection open during the measurement with the use of an absolute pressure sensor, then it will actually be able to read the barometric pressure.

How to choose between the two types

A general rule says that if you wish to measure a pressure that can be affected by changes in atmospheric pressure, including the level of liquid an open tank consists of, then you should go for the vented gauge pressure. That being said, you need to focus on the pressure reading minus the measurement of the atmospheric pressure. On the other hand, pressures that are not affected by changes in atmospheric pressure should be measured with the use of an absolute pressure sensor. This can be applied to measurements of a sealed container that contains a liquid. In this occasion, if you used a gauge sensor instead, then any changes in the barometric pressure would cause important changes to the sensor's reading. However, the pressure inside the container would still be the same.