Oil Flow Measurement Essentials for Industry

The world economy depends heavily on oil for everything from manufacturing and chemical processing to power generation and transportation. Accurately measuring the flow of oil is essential for cost control, process efficiency, safety, and regulatory compliance in any industry that uses or produces it. But "oil" isn't a single material. From the low viscosity of refined diesel fuel to the thick, abrasive nature of crude oil or lube oil and the intense heat of thermal oils, this broad category of fluids has a wide range of characteristics.

Because there is no "one-size-fits-all" oil flow meter, this diversity poses a serious problem and challanges. A thorough understanding of the oil's characteristics, the process parameters, and the particular measurement goal is necessary to choose the best oil flow metering instrument.

This thorough article is intended to serve as your go-to source for measuring oil flow. With links to in-depth resources provided along the way, we will discuss the crucial differences between volumetric and mass flow, go over the latest oil meter technologies, address particular measurement problems and tough points, and look at important applications.

Accurate oil measurement gives you the information you need to make wise financial and operational choices. The main advantages consist of:

Choosing whether to measure mass or volume is the first important consideration when choosing an oil flow meter.

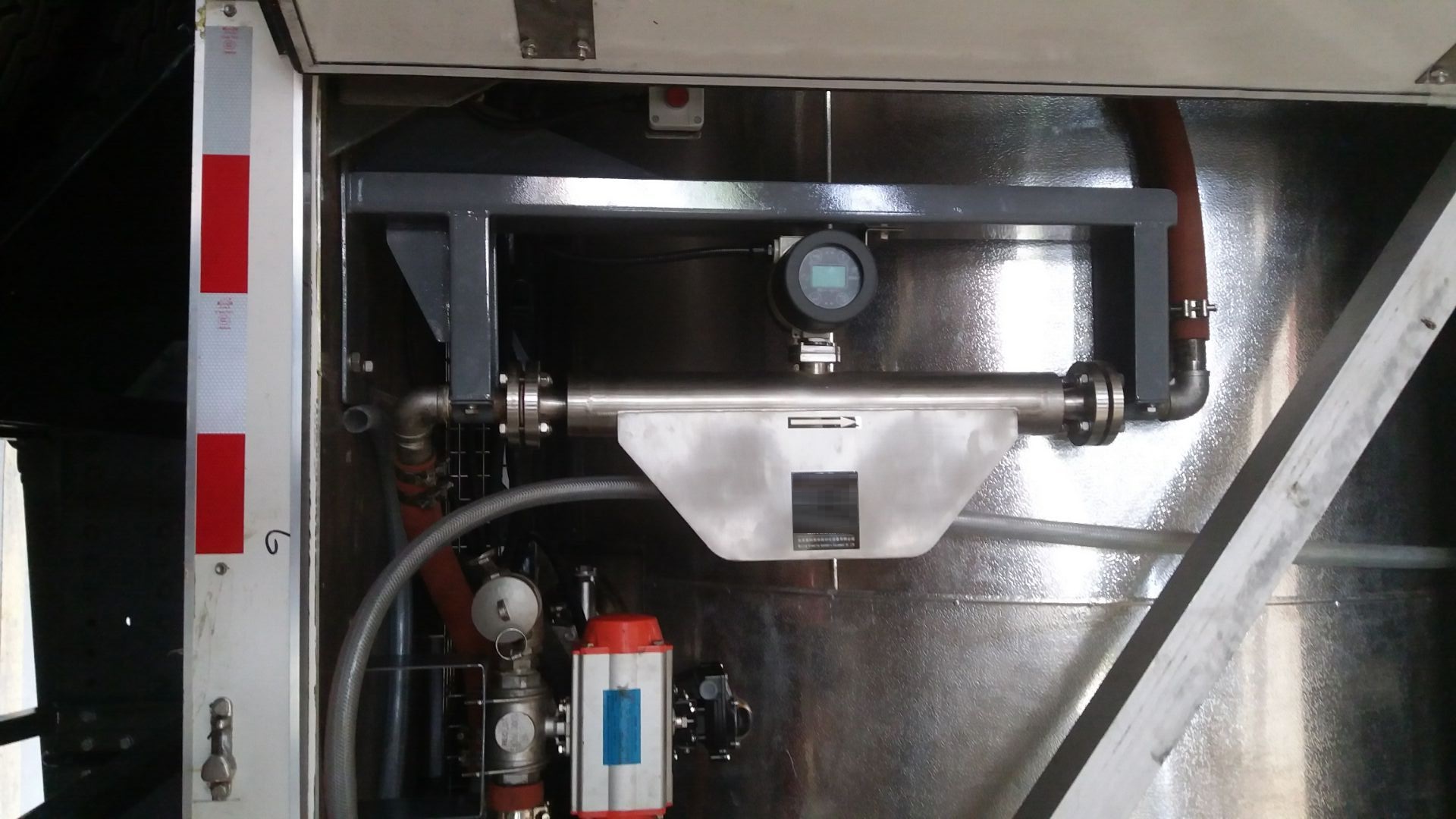

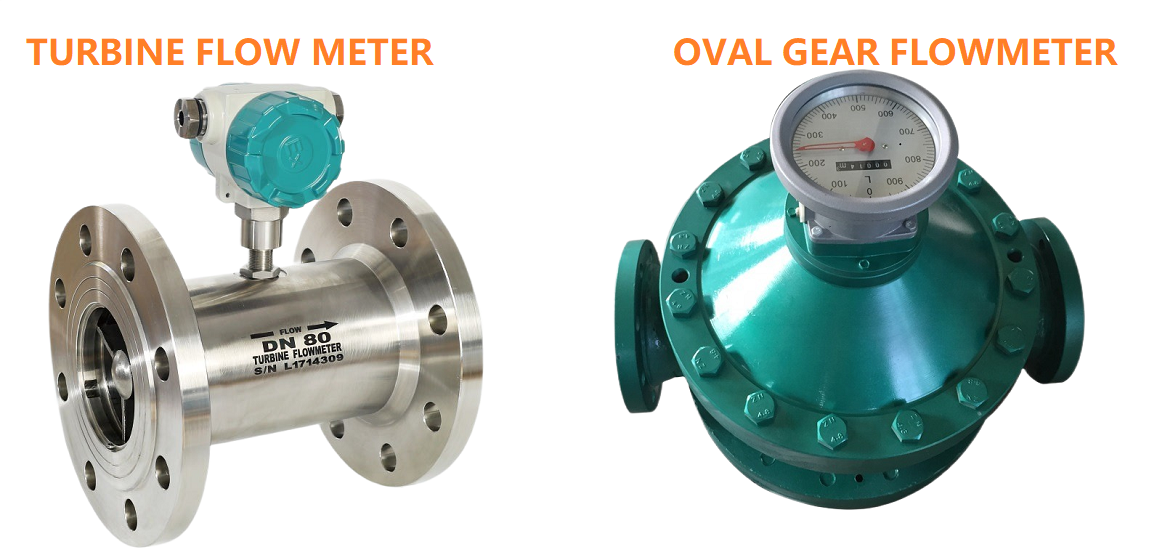

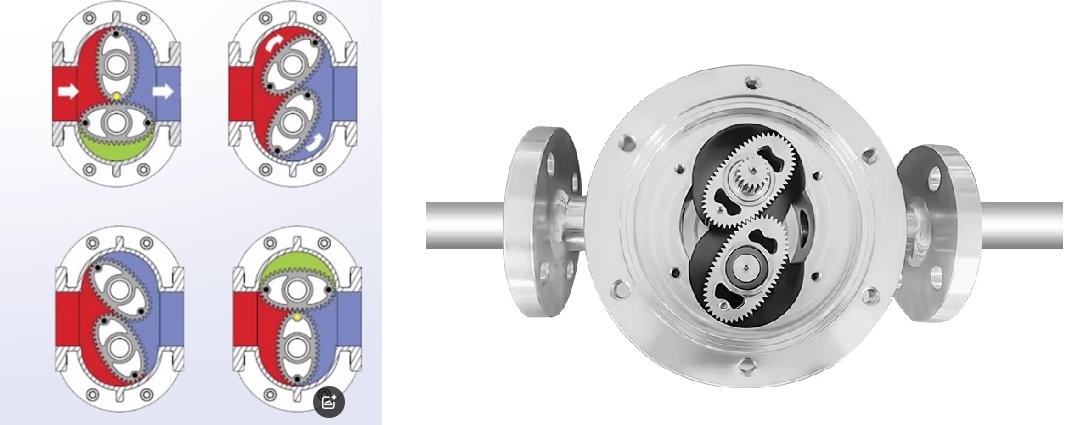

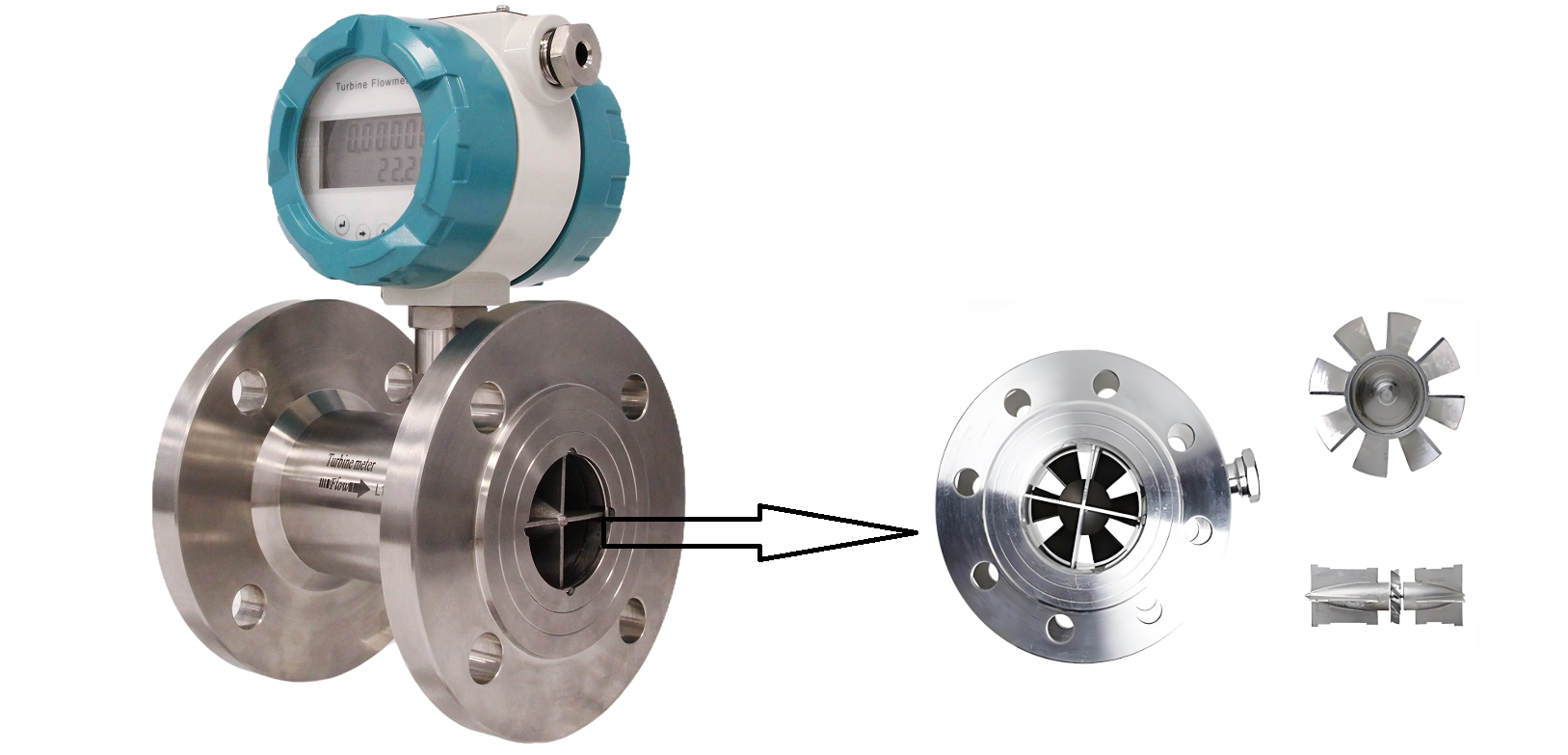

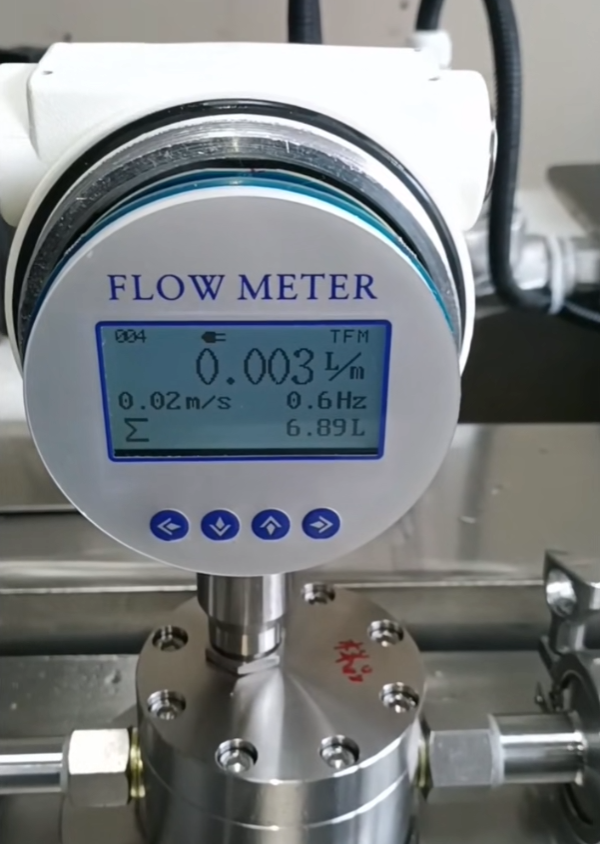

The volume of oil passing a point in a given amount of time (e.g., liters per minute, gallons per minute) is calculated using Volumetric Flow Measurement. Volumetric technologies include turbine flow meters (TUF) and oval gear flow meter . Since the volume of oil expands when heated and contracts when cooled, variations in fluid properties may have an impact on the accuracy of this straightforward and efficient method.

The mass of oil passing a point in a given amount of time (e.g., kilograms per hour, pounds per minute) is determined by Mass Flow Measurement. Mass is directly measured by Coriolis flow meters. Since the mass of the fluid remains constant regardless of temperature ,viscosity or pressure, this measurement approach is intrinsically more accurate for oil. Direct mass measurement is the industry standard for high-value applications such as custody transfer trading purpose.

Despite the existence of numerous technologies, the performance and dependability of three different types of flow meters have made them the industry standard for the vast majority of oil applications.

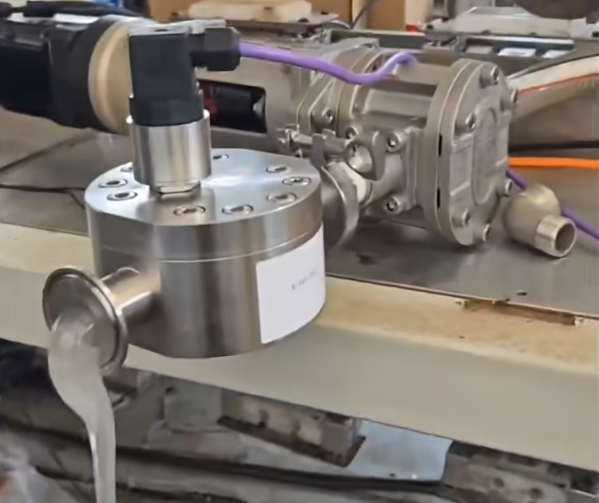

The reliable mainstays of volumetric oil measurement are oval gear meters. They are extremely accurate and dependable because they employ two interlocking gears to trap and pass a precise, known volume of liquid with each rotation.

Clean, refined oils with low viscosity can be measured affordably with turbine flow meters.

Measuring small quantities is crucial for applications such as small burner fuel lines, R&D test benches, and fuel additive injection. Micro-flow configurations are offered for both Coriolis and Oval Gear technologies. These specialized low flow oil flow meters are designed to provide high accuracy at flow rates that are frequently expressed in milliliters per minute (ml/min flow meter for oil). Even the smallest amounts of fluid can be precisely tracked and controlled by selecting the appropriate low volume industrial oil flow meter.

Extremely viscous substances include asphalt, heavy crude oil, and some lubricants. Coriolis meters and positive displacement are excellent at this main problem. They can measure thick, slow-moving liquids precisely where other meters can't because their measurement principles don't rely on a consistent flow profile. See our guide to high viscosity flow meters for a more thorough look.

Applications that work under extreme pressure include wellhead injection and hydraulic systems. The flow meter's mechanical design is crucial in these situations. To guarantee safe and dependable operation, high pressure oil flow sensor must be chosen with the proper pressure ratings and sturdy process connections (such as high-pressure flanges or fittings). For these demanding conditions, we have specially designed our digital hydraulic oil flow meters.

High temperatures are required for the measurement of many oils, including heavy fuel oil fed into a boiler or thermal oils in heat transfer systems. In order to safeguard the oil transmitter electronics and guarantee that the oil sensor materials can tolerate the heat, this calls for instruments with unique construction. The proper materials and configurations, such as remote-mounted transmitters or with cooling devices, can be chosen with the aid of a thorough guide on high-temperature flow meters.

Impurities such as sand, water, and gas (multiphase flow) are frequently found in crude oil. For mechanical meters, this is very harsh. A Coriolis mass flow meter is the only dependable option for measuring unfiltered or abrasive oils because it has no moving parts and an obstructionless design. Efficient upstream filtration is crucial for other meters, such as Oval Gear or Turbine.

There is always a need to measure oil. These are a few of the most typical uses for our instruments.

Crude oil's high viscosity, impurities, and high value make measuring it a challenging task. For custody transfer, Coriolis technology is preferred, and large-diameter meters are frequently needed. See our

The accurate monitoring of gear and hydraulic oils is essential to the maintenance of heavy machinery. These vital systems use our flow meters to monitor consumption and find leaks. Find out more about our

The food industry needs to measure different edible oils accurately and hygienically. We offer customized solutions for various kinds, such as

Specialized oils with special qualities are used in many industrial processes.

Choosing the best

Our specialty at Silver Automation Instruments is offering the appropriate flow measurement equipment for your particular problem. From our extensive selection of