1. Industry Overview

Flow meter for Fluorochemical and specialty gas industry

The fluorochemical and specialty gas industry plays a vital role in Southeast Asia’s growing manufacturing and energy markets. Countries such as Vietnam, Malaysia, Thailand, and Singapore are seeing strong growth in refrigerant production, fluoropolymer synthesis, semiconductor manufacturing, and fine chemical processing. These industries handle a wide range of liquefied gases, corrosive fluids, and dense chemical intermediates that require accurate, safe, and stable flow measurement.

In processes involving chlorofluorocarbons (CFCs), hydrofluoroolefins (HFOs), propylene-based compounds, and halogenated intermediates, precise flow and density monitoring are essential for quality control, batch dosing, and regulatory compliance. For such demanding applications, the

Coriolis mass flow meter has become the gold standard for reliable measurement under varying pressure, temperature, and viscosity conditions.

2. Characteristics of the Measured Media

The materials commonly used in the fluorochemical and specialty gas industry exhibit extreme variations in density, temperature, volatility, and corrosiveness. A few representative examples (based on real industrial inquiries) include:

-

CTFE (Chlorotrifluoroethylene) – A refrigerant and monomer for fluoropolymer production, with a density around 1390 kg/m³ and a boiling point of −26 °C. The liquid is stored and metered between −27 °C and −20 °C under 400–700 kPa.

-

C₄F₆ (Perfluorobutene derivatives) – A fluorinated gas used in semiconductor etching and precision cooling applications. With density around 1600 kg/m³, it is typically handled in pressurized liquid form between 200–600 kPa at temperatures from −10 °C to +35 °C.

-

Propylene (CxFyClz mixtures) – A reactive hydrocarbon used in refrigerant blending and fine chemical synthesis. Operating at 5–10 °C and 500 kPa, flow ranges can vary from 10 kg/h to over 2000 kg/h.

-

RL-316 / RC-316 liquids – Dense, corrosive intermediates with densities near 1750–1810 kg/m³, used in polymer or specialty chemical reactions.

-

DCl₂-based chemicals – Strongly corrosive halogen compounds that require resistant materials and stable measurement at low temperatures.

These parameters are given as examples from customer inquiries and do not represent the full diversity of the industry.

They reflect typical working conditions in fluorochemical, refrigerant, and electronic gas applications, where precise and robust flow monitoring is crucial.

3. Technical Challenges in Flow Measurement

Flow measurement in the fluorochemical and specialty gas industry is particularly challenging because of the complex behavior of fluids involved:

-

High density and viscosity variations cause nonlinear errors in mechanical or volumetric flow meters.

-

Corrosive and halogenated fluids require full stainless steel flow sensor or Hastelloy wetted parts to prevent contamination.

-

Cryogenic conditions (below −20 °C) can lead to sensor drift, condensation, or freezing in conventional flow sensors.

-

Multiphase flow (liquid–vapor transitions) complicates the calibration of differential pressure and turbine flow meters.

-

Compact installation constraints, as most process lines use ½″–1″ camlock or threaded connections, demand small but highly accurate meters.

Traditional volumetric technologies such as turbine, vortex, or differential pressure flow meters cannot fully address these issues, especially when precise mass flow and density measurement are required for process control or billing.

4. Why Coriolis Flow Meters Are the Ideal Solution

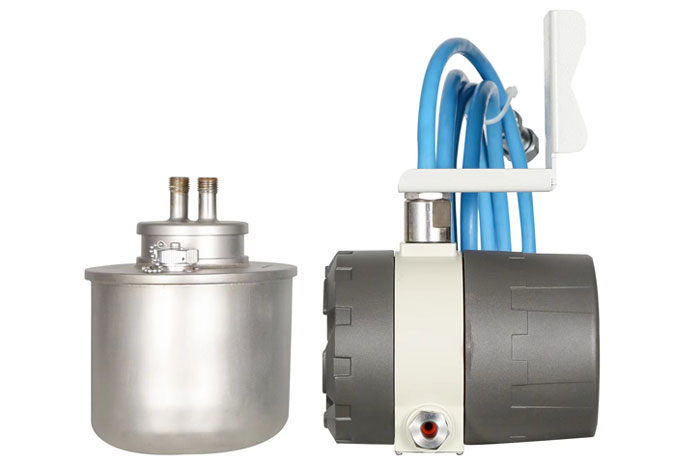

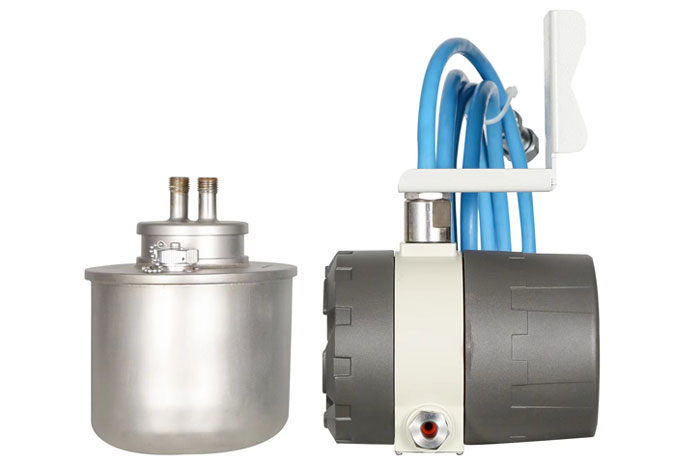

Coriolis mass flow meter for

fluorochemical and specialty gas

The Coriolis mass flow meter measures the actual mass flow rate by detecting the phase shift caused by fluid momentum in vibrating flow tubes. This principle makes it independent of fluid density, pressure, temperature, or viscosity, delivering unmatched precision across a wide range of media.

For fluorochemical and specialty gas applications, the advantages are clear:

-

Direct mass flow measurement without the need for temperature or pressure compensation.

-

High accuracy (±0.1~0.2 % of reading) and repeatability even for low flow rates below 1 kg/h.

-

Integrated density and temperature output, enabling simultaneous quality and concentration monitoring.

-

Cryogenic capability, ensuring stability down to −50 °C for liquefied gases like CTFE or C₄F₆.

-

Corrosion-resistant materials, including 316L stainless steel and Hastelloy, to handle halogenated and acidic media.

-

Compact and removable design, allowing mobile skid or truck-mounted metering using ½″–¾″ camlock connections.

-

Digital signal compatibility (4–20 mA, HART, Modbus RTU) for integration with PLC or DCS systems.

By eliminating the need for additional sensors or compensations, Coriolis flow meters simplify system design and improve overall process safety and traceability — key priorities in chemical and refrigerant manufacturing.

5. Example Applications (Based on Real Inquiries)

Silver Automation Instruments has received multiple inquiries from Southeast Asia’s fluorochemical and specialty gas plants, illustrating the wide range of use cases:

-

A ¾″ Coriolis mass flow meter used to measure CTFE at −25 °C, 400–700 kPa, with flow from 10–100 kg/h.

-

A ½″ meter for Propylene mixtures at 5–10 °C, 500 kPa, and flow range of 13–60 kg/h.

-

A 65A Coriolis flow meter for RL-316 chemical liquids with density 1810 kg/m³, operating at 34 °C and 90–100 kPa.

-

A C₄F₆ application in the semiconductor industry, with flow range 0.5–10 kg/h, density 1650 kg/m³, and pressure 350–600 kPa.

Each case demonstrates how a single Coriolis flow meter design can adapt to multiple process conditions — from low-temperature refrigerant filling to dense liquid chemical blending.

6. Benefits for the Fluorochemical and Specialty Gas Industry

By adopting Coriolis mass flow meters from Silver Automation Instruments, industrial operators in the fluorochemical sector can achieve:

-

Improved production efficiency, thanks to precise control of reactant feed rates and batch quantities.

Batch controller

-

Enhanced safety, with accurate detection of leaks or flow deviations in critical systems.

-

Reduced maintenance, since Coriolis meters have no moving parts and minimal calibration drift.

-

Better quality assurance, through simultaneous monitoring of mass, density, and temperature.

-

Regulatory compliance, supporting ISO, CE, ATEX standards for trade and custody transfer applications.

Whether used in fluoropolymer monomer feed systems, refrigerant filling lines, or semiconductor gas distribution, the Coriolis flow meter ensures reliable and repeatable performance under the most challenging conditions.

7. Conclusion

As Southeast Asia continues to strengthen its position in fluorochemical production, refrigerant manufacturing, and specialty gas supply, accurate flow measurement becomes a cornerstone of industrial success. The Coriolis mass flow meter stands out as the only technology that combines direct mass flow measurement, high precision, and excellent material compatibility in one instrument.

Silver Automation Instruments delivers a full range of Coriolis flow meters — from compact ½″ models for pilot systems to large 100 mm sensors for bulk chemical operations. With proven performance, local support, and cost-effective pricing, Silver Automation Instruments is your trusted partner for flow measurement in the fluorochemical and specialty gas industry.

Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW

Coriolis flow controller2024/05/14How does a Coriolis flow controller work ?A Coriolis flow controller is a sophisticated tool used in fluid management. It merges the capabilities of a Coriolis flow meter with those of a control valve...VIEW Coriolis flow meter for chlor-alkali industry2024/05/26The chlor-alkali industry relies heavily on accurate and stable measurements for chlorine gas and caustic soda (sodium hydroxide). Coriolis Mass flow meters are essential tools in this industry due to...VIEW

Coriolis flow meter for chlor-alkali industry2024/05/26The chlor-alkali industry relies heavily on accurate and stable measurements for chlorine gas and caustic soda (sodium hydroxide). Coriolis Mass flow meters are essential tools in this industry due to...VIEW High Accuracy mass flow meter/flow controller2025/03/02High-precision gas flow meter/controller with accuracy of ±0.5% of full scale. Thermal dispersion principle for gas, air ,CO2,N2,O2,He,HCl,H2 etc. Response time 0.2s.VIEW

High Accuracy mass flow meter/flow controller2025/03/02High-precision gas flow meter/controller with accuracy of ±0.5% of full scale. Thermal dispersion principle for gas, air ,CO2,N2,O2,He,HCl,H2 etc. Response time 0.2s.VIEW Coriolis Flow Meter for Latex Flow Measurement2025/03/27Silver Automation Instruments recently encountered multiple customer inquiries regarding latex flow measurement in different applications, including rubber glove manufacturing , Latex Compound for Mat...VIEW

Coriolis Flow Meter for Latex Flow Measurement2025/03/27Silver Automation Instruments recently encountered multiple customer inquiries regarding latex flow measurement in different applications, including rubber glove manufacturing , Latex Compound for Mat...VIEW Turbine Flow meter for corrosive liquid2023/03/17What is turbine flow meter for corrosive liquid?A turbine flow meter is a type of flow meter that measures the rate of fluid flow by utilizing a turbine wheel that rotates as the fluid passes through ...VIEW

Turbine Flow meter for corrosive liquid2023/03/17What is turbine flow meter for corrosive liquid?A turbine flow meter is a type of flow meter that measures the rate of fluid flow by utilizing a turbine wheel that rotates as the fluid passes through ...VIEW Corrosive liquid flow meter2019/08/02In the industrial production process, many media are slightly or strong corrosive. We need to measure the flow rate of these aggressive fluids. How to choose the flow instrumentation for measuring cor...VIEW

Corrosive liquid flow meter2019/08/02In the industrial production process, many media are slightly or strong corrosive. We need to measure the flow rate of these aggressive fluids. How to choose the flow instrumentation for measuring cor...VIEW