Introduction to Diaphragm Pressure Gauge Applications

In the process of chemical production, pressure is one of the important process parameters that often need to be measured. Due to the diverse types and complex properties of process media, such as corrosion, viscosity, easy solidification, crystallization, etc., pressure measurement has become difficult. Moreover, due to the varying degrees of vibration that often occur in certain areas where the process medium flows, such as after the pump, it also affects the measurement of pressure. More information:

[ Why we need diaphragm seals for pressure gauges or transmitters?]

Some corrosive,viscous or easy crystallization liquids needs pressure measurement

In these cases, it is usually necessary to add "isolation tank" or "buffer tank" devices, or to add "steam tracing" (or "electric tracing") insulation, or to use "

diaphragm pressure gauges" in addition to the above measures. However, in many cases, the problem still cannot be solved.

Why Choose Diaphragm Pressure Gauges?

Tough applications needs diaphragm pressure gauges

This comprehensive guide introduces a type of pressure gauge called "diaphragm pressure gauge" that offers wide range of adaptability and can eliminate difficulties caused by various factors mentioned above. It is composed of a regular

Bourdon tube pressure gauge and an isolation diaphragm chamber, or it can be composed of a regular

electric contact pressure gauge or an electric remote transmission pressure gauge and an isolation diaphragm chamber. More information:

[In 3 situations when diaphragm seal pressure gauges are needed ]

Key applications include:

-

Corrosive media measurement in chemical processing

-

High-viscosity fluid monitoring in manufacturing

-

Crystallizing substance pressure measurement

-

Vibration-prone environments after pumps and compressors

-

High-temperature process monitoring

Construction and Working Principle

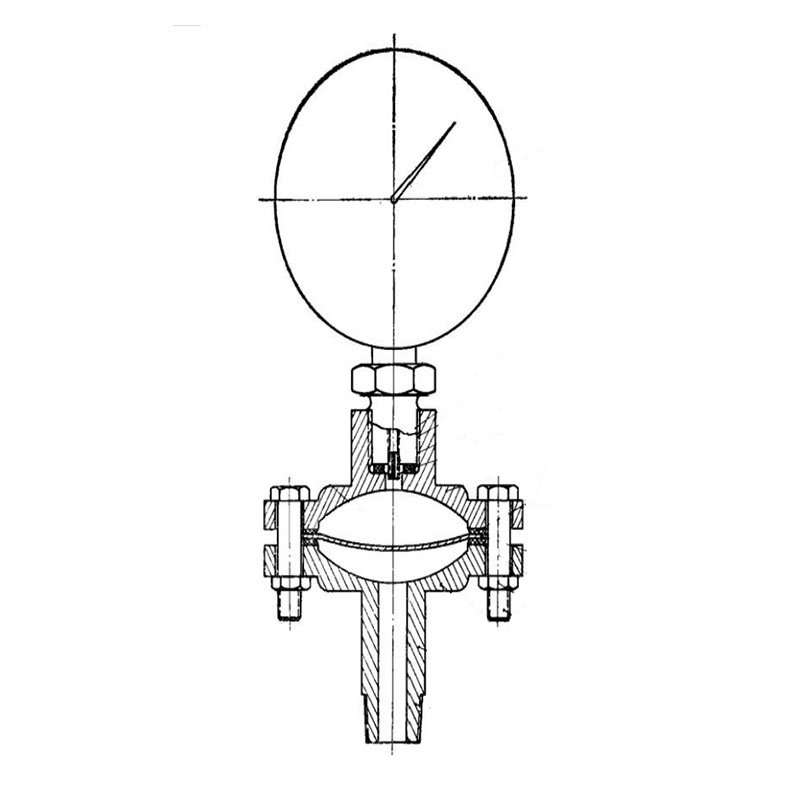

Diaphragm Pressure Gauge Design and Components

As shown in the figure, the isolation diaphragm chamber is composed of two flange-shaped diaphragm chambers with curved surfaces on top and bottom. The lower end of the lower diaphragm chamber is equipped with M20 × 1.5 external thread connection or M15 (i.e. 1/2") tapered pipe thread, M25 (i.e. 1") tapered pipe thread connection, so as to be directly connected to the process valve. The outer side of the upper section of this connection is hexagonal, which facilitates installation and removal work.

Diaphragm pressure gauge design

Key Components:

-

Upper and Lower Gaskets (6, 8): The edge of the inner circle in contact with diaphragm (7) should be rounded to prevent the membrane from being cut by the sharp gasket edge.

-

Upper Interface (12): There is an M20 × 1.5 internal thread interface on the upper end of the diaphragm chamber, with a hexagonal shape on the outer side, used to connect pressure gauge (15). There is a sealing gasket (10) at the bottom of the interface.

-

Constant Orifice Tube (11): A section of internal thread (13) is drilled into the pressure inlet of the pressure gauge using an M4 × 0.7 taper tap, in order to screw in a constant orifice tube used to eliminate process medium vibration. The constant orifice tube is made using M4 × 10 bolts with a small hole having an inner diameter of 1.0 mm.

Working Principle of diaphragm pressure gauge

The space above the isolation diaphragm is filled with pressure transmission fluid and the pressure of the measured medium reaches the Bourdon tube pressure gauge through the diaphragm and the transmission fluid.

The isolation membrane

(chemical seal) can be made of:

-

Corrosion-resistant metal foil

-

Metal foil coated with anti-corrosion layer

-

Plastic membrane

-

Rubber membrane

In order to prevent the rupture of the membrane due to compression, its size should be large enough to offset the total volume change of the pressure gauge Bourdon tube and the volume change of the compressed gas in the tube caused by compression deformation.

Standard Dimensions

For the convenience of material selection, the size of the diaphragm chamber we chose is the pipe fitting size with a diameter of 50 millimeters (i.e. 2"), so the diameter of the diaphragm is 78 millimeters and the effective working diameter is 62 millimeters. The sealing gasket above and below the diaphragm is a pipe fitting gasket with a diameter of 50 millimeters.

Diaphragm Materials and Selection Guide

Comprehensive Material Properties Table

PTFE Diaphragm pressure gauge

The following table lists the properties of some diaphragm materials and the thickness of the membrane for reference:

|

Material Name

|

Performance Characteristics

|

Thickness (mm)

|

Remarks

|

|

PTFE (Polytetrafluoroethylene)

|

Resistant to strong acids, strong alkalis, oil, and temperatures up to 250°C

|

0.02~0.2

|

0.2mm can use one or two layers, and 0.02mm can use three layers

|

|

Polypropylene

|

Resistant to strong acids, strong alkalis, oil, and temperatures ranging from 100 to 150°C

|

0.04~0.1

|

Good chemical compatibility

|

|

PEEK (Polyetheretherketone)

|

Resistant to strong acids, strong alkalis, oil, and temperatures up to 290°C

|

0.04~0.1

|

Excellent high-temperature performance

|

|

HDPE (High-Density Polyethylene)

|

Acid and alkali resistant, used for temperatures ranging from -20 to 60°C

|

0.04~0.1

|

Cost-effective for moderate conditions

|

|

Fluororubber (Viton)

|

Acid and alkali resistance, temperature resistance up to 200°C, maximum 250°C

|

0.2~0.4

|

Elasticity and flexibility are far better than plastic membrane

|

|

Silicone Rubber

|

Acid and alkali resistance, temperature resistance up to 200°C, maximum 250°C

|

0.2~0.4

|

Elasticity and flexibility are far better than plastic membrane

|

|

Nitrile Rubber (NBR)

|

Acid resistant, alkali resistant, oil resistant, and temperature resistant to 160°C

|

0.2~0.4

|

Elasticity and flexibility are far better than plastic membrane

|

|

Copper Foil

|

Good conductivity, moderate corrosion resistance

|

0.04

|

It is best to prefabricate it into a concave arc shape first

|

|

Stainless Steel Foil

|

Excellent corrosion resistance for most media

|

0.04

|

It is best to prefabricate it into a concave arc shape first

|

|

Metal Foil with PTFE Coating

|

Combines metal strength with PTFE chemical resistance

|

0.04~0.1

|

It is best to prefabricate it into a concave arc shape first

|

|

Metal Foil with Epoxy Resin Coating

|

Acid, alkali, oil resistance, temperature resistance not exceeding 80°C

|

0.04~0.1

|

It is best to prefabricate it into a concave arc shape first

|

|

Metal Foil with Furan Resin Coating

|

Acid and alkali resistance, oil resistance, temperature resistance up to 200°C, maximum 290°C

|

0.04~0.1

|

It is best to prefabricate it into a concave arc shape first

|

Material Selection Recommendations

We use one or two layers of

PTFE membrane with a thickness of 0.2 millimeters, or three layers of PTFE membrane with a thickness of 0.02 millimeters as the diaphragm. The diaphragm pressure gauge assembled from this membrane is installed on the distillation tower, raw material pump, and reflux pump to measure pressure. The membrane rarely breaks, and the error of the pressure gauge is still within the original accuracy level.

Pressure Transmission Fluid Requirements

Critical Selection Criteria

The boiling point of the pressure transmission fluid should be higher than the temperature of the measured medium, and it must be clean and have no corrosive contact with the pressure gauge. If the boiling point of the pressure transmission liquid is lower than the process temperature, during the pressure measurement process, the saturated vapor pressure generated by the transmission liquid in a sealed state becomes an additional pressure. When the process medium pressure drops due to fluctuations, the isolation membrane will be affected by this additional pressure and burst.

Recommended Transmission Fluids

Silicon oil is often used as diaphragm pressure gauge transfer liquid

We use the following pressure transfer liquids in practical applications:

-

Glycerol with a boiling temperature of 290°C

-

Liquid paraffin with a boiling temperature of 340°C

These fluids can achieve satisfactory results when applied to medium temperatures ranging from 90°C to 270°C. From this, it can be seen that the viscosity of the pressure transmission fluid does not need to be considered as a critical factor.

Constant Orifice Tube Specifications

The aperture of the constant orifice tube should be made as small as possible, with the principle of not having a pressure reducing effect. We use a constant orifice tube with an aperture of 1.0 mm, which has good anti-vibration capability.

Originally, there were several pressure gauges that were subjected to strong vibrations from the process medium, and the gauge needles quickly and significantly swayed to the point where the pointers were difficult to read with the naked eye. When constant orifice tubes were added, the readings became stable.

If the pressure of the process medium only experiences slight vibrations or slow changes, such as the pressure on certain containers or distillation towers, constant orifice tubes may not be necessary.

Installation and Assembly Guidelines

Step-by-Step Assembly Process

When assembling the diaphragm pressure gauge, follow these critical steps:

1.First clamp the diaphragm chamber onto the vise for pre-assembly, and do not tighten the fastening bolts

2.Inject pressure transfer fluid into the diaphragm chamber to make the liquid level flush with the internal thread interface

3.Then screw in the Bourdon tube pressure gauge. At this time, the diaphragm will slide downward in a concave arc shape

4.Tighten all the bolts again. During the tightening process, the two bolts facing each other should be tightened together, not along one side in sequence, otherwise air will enter the diaphragm chamber and the diaphragm is prone to rupture

5.The upper diaphragm chamber must be tightly sealed to prevent the membrane from breaking due to leakage

Installation Considerations for Special Applications

High Freezing Point Media

For high freezing point media, in order to prevent condensation blockage in the pressure measuring device, according to the principle of convective heat exchange, when installing a diaphragm pressure gauge, a connecting pipe with a diameter of 15 millimeters (1/2") or 25 millimeters (1") can be used to take pressure at an upward angle of 45 degrees or vertically upward.

The pressure gauge installed in this way does not require any other insulation measures for the process medium with a solidification point of nearly 80°C in an indoor environment of 20°C, and there is no condensation blockage in the pressure line. In the harsh winter conditions of minus 16°C outdoors, only mineral wool insulation is used, and the pressure gauge operates normally.

High Viscosity and Contaminated Media

Diaphragm pressure gauge for high viscosity liquid

For pressure measurement of high viscosity and severely contaminated media, simply increase the size of the connecting pipe of the lower diaphragm chamber and the connecting pipe of the pressure measuring device.

Highly Corrosive Media

For pressure measurement of highly corrosive process materials, it is only necessary that the materials of the lower diaphragm chamber and isolation membrane meet the requirements for anti-corrosion contact. Due to its simple shape and ease of production, the lower diaphragm chamber has a wide range of adaptability in terms of anti-corrosion requirements.

Applications for Challenging Process Media

Due to the constant orifice tube damping device of the diaphragm pressure gauge, it can eliminate the influence of strong vibration of the process medium on pressure measurement.

Chemical Processing Applications

Typical applications include:

-

Distillation tower pressure monitoring

-

Raw material pump pressure measurement

-

Reflux pump system monitoring

-

Reactor vessel pressure control

-

Corrosive chemical transfer lines

Temperature Range Applications

The diaphragm pressure gauge system can handle:

-

Cryogenic applications down to -20°C

-

High-temperature processes up to 290°C

-

Thermal shock conditions with proper fluid selection

-

Crystallizing media that would clog conventional gauges

Advantages and Benefits

Key Benefits of Diaphragm Pressure Gauge Technology

Due to the fact that the diaphragm pressure gauge is composed of a slightly modified Bourdon tube pressure gauge and an isolation diaphragm chamber, it offers several key advantages:

Cost effective pressure measurement instruments

Cost-Effectiveness

-

Easy to obtain materials and simple to construct

-

The isolation diaphragm chamber can be manufactured using precision mass production processes with low cost

-

The diaphragm is not easily broken and consumes very little material

Wide Applicability

Diaphragm pressure gauge has wide applications

-

Widely applicable - as long as appropriate lower diaphragm chambers and isolation membranes are selected, it can widely meet the pressure measurement requirements for various process media

-

There is no need to install "isolation tanks", "buffer tanks", or take measures such as "steam tracing" (or "electric tracing")

-

Installation and maintenance are simple

Reliability and Performance

-

Eliminates vibration effects through constant orifice tube damping

-

Maintains original accuracy levels of the base pressure gauge

-

Provides excellent chemical compatibility through proper material selection

-

Handles extreme temperatures with appropriate transmission fluids

Selection Guide for Your Application

How to Choose the Right Diaphragm Pressure Gauge Configuration

When selecting a diaphragm pressure gauge for chemical processing applications, consider these critical factors:

Process Media Characteristics

-

Chemical compatibility requirements (acids, bases, solvents)

-

Operating temperature range (cryogenic to high-temperature)

-

Viscosity levels (thin liquids to heavy oils)

-

Crystallization tendencies (solidification potential)

-

Contamination levels (clean to heavily contaminated)

Environmental Conditions

-

Vibration levels (mild to severe)

-

Installation orientation (vertical, horizontal, angled)

-

Ambient temperature (indoor/outdoor conditions)

-

Hazardous area classification (explosion-proof requirements)

Performance Requirements

-

Accuracy specifications (standard to precision)

-

Pressure range (low to high pressure)

-

Response time (fast vs. damped response)

-

Signal output needs (local indication vs. remote transmission)

Material Selection Matrix

|

Application Type

|

Recommended Diaphragm Material

|

Transmission Fluid

|

Temperature Range

|

|

Strong Acids/Bases

|

PTFE or Fluororubber

|

Glycerol or Liquid Paraffin

|

Up to 250°C

|

|

High Temperature

|

PEEK or Metal with PTFE coating

|

Liquid Paraffin

|

Up to 290°C

|

|

Cryogenic

|

Stainless Steel or PTFE

|

Glycerol

|

Down to -20°C

|

|

Oil & Petrochemical

|

Nitrile Rubber or Fluororubber

|

Liquid Paraffin

|

Up to 200°C

|

|

General Chemical

|

Polypropylene or PTFE

|

Glycerol

|

Up to 150°C

|

Need Expert Guidance for Your Diaphragm Pressure Gauge Selection?

Selecting the optimal diaphragm pressure gauge configuration requires careful analysis of your specific process conditions, chemical compatibility requirements, and performance specifications. With multiple material options and configuration possibilities, the selection process can be complex and critical to your process safety and reliability.

Our pressure measurement specialists have extensive experience with diaphragm pressure gauge applications across diverse chemical processing environments and can help you:

✅ Analyze your process media characteristics and recommend compatible diaphragm materials

✅ Evaluate temperature and pressure requirements to select appropriate transmission fluids

✅ Design custom diaphragm chamber configurations for challenging installation conditions

✅ Provide detailed specifications for material compatibility and corrosion resistance

✅ Offer installation guidance and technical support throughout your project lifecycle

Don't risk process downtime or safety issues with improper pressure gauge selection. Contact our technical experts today for a comprehensive evaluation of your diaphragm pressure gauge requirements.

Contact our pressure measurement specialists today for a free consultation and customized recommendation for your specific chemical processing application.

[Get Your Expert Consultation →]

Low Pressure Diaphragm Seal Pressure Gauge (-500~2500 mmWC)2020/07/13Dialsize: 150mm. oil filled type, not dry type pressure gauge. (With liquid filled case for applications with high dynamicpressure pulsations or vibration)Case and ring Material: 304 StainlessSteel.We...VIEW

Low Pressure Diaphragm Seal Pressure Gauge (-500~2500 mmWC)2020/07/13Dialsize: 150mm. oil filled type, not dry type pressure gauge. (With liquid filled case for applications with high dynamicpressure pulsations or vibration)Case and ring Material: 304 StainlessSteel.We...VIEW Chlorine Pressure Gauge2021/03/17What is Chlorine (Cl2 )?Chlorine Pressure Gauge is kind of pressure measurement device.Chlorine gas (Cl2 ) is a yellow-green gas under normal temperature and pressure, with a strong pungent odor, and ...VIEW

Chlorine Pressure Gauge2021/03/17What is Chlorine (Cl2 )?Chlorine Pressure Gauge is kind of pressure measurement device.Chlorine gas (Cl2 ) is a yellow-green gas under normal temperature and pressure, with a strong pungent odor, and ...VIEW Low pressure diaphragm seal Pressure Gauge2020/01/22Low pressure Diaphragm seal pressure gaugeis for pressure measurement within 60Kpa (6118 mmWC).Pressure Gauge size: 60mm, 100mm, 150mmDiaphragm seal: Flange type, and stainlesssteel materialLiquid fil...VIEW

Low pressure diaphragm seal Pressure Gauge2020/01/22Low pressure Diaphragm seal pressure gaugeis for pressure measurement within 60Kpa (6118 mmWC).Pressure Gauge size: 60mm, 100mm, 150mmDiaphragm seal: Flange type, and stainlesssteel materialLiquid fil...VIEW Resin phenolic pressure gauge2019/04/16Safety Resin phenolic pressure gauge with solid baffle wall designedExcellent load-cycle stability and shock resistancePHENOL CASE PRESSURE GAUGE Technical SpecificationsNominal Size: 41/2” Pressure...VIEW

Resin phenolic pressure gauge2019/04/16Safety Resin phenolic pressure gauge with solid baffle wall designedExcellent load-cycle stability and shock resistancePHENOL CASE PRESSURE GAUGE Technical SpecificationsNominal Size: 41/2” Pressure...VIEW Flanged Mounted Diaphragm Seal Pressure Gauge2018/12/04Diaphragm seal pressure gauge is designed, manufactured, and factory tested to maximize performance, increase pressure gauge application durability, and assure operator safety.VIEW

Flanged Mounted Diaphragm Seal Pressure Gauge2018/12/04Diaphragm seal pressure gauge is designed, manufactured, and factory tested to maximize performance, increase pressure gauge application durability, and assure operator safety.VIEW Diaphragm seal with capillary Pressure Gauge2018/12/04Industrial Pressure Gauge + Capillary + Diaphragm seal ,Capillary between pressure gauge and diaphragm seal (chemical seal) can avoid the direct contact with the measured fluids because of the increasing temperature, pressure spikes and so on.VIEW

Diaphragm seal with capillary Pressure Gauge2018/12/04Industrial Pressure Gauge + Capillary + Diaphragm seal ,Capillary between pressure gauge and diaphragm seal (chemical seal) can avoid the direct contact with the measured fluids because of the increasing temperature, pressure spikes and so on.VIEW All welded Diaphragm seals Pressure Gauge2018/11/26All welded Diaphragm seals thread connection bourdon tube pressure gauge for high pressure and high temp application.VIEW

All welded Diaphragm seals Pressure Gauge2018/11/26All welded Diaphragm seals thread connection bourdon tube pressure gauge for high pressure and high temp application.VIEW Tri Clamp Hygienic Diaphragm Seal Pressure Gauge2018/12/04Tri Clamp Hygienic Diaphragm Seal Pressure Gauge is perfect Choice for food & beverage, diary, biotech, pharmaceutical and other sanitary applications.VIEW

Tri Clamp Hygienic Diaphragm Seal Pressure Gauge2018/12/04Tri Clamp Hygienic Diaphragm Seal Pressure Gauge is perfect Choice for food & beverage, diary, biotech, pharmaceutical and other sanitary applications.VIEW Flush Flanged diaphragm Seal Pressure Gauge2018/11/26Flush Flanged diaphragm seal pressure gauge for protecting the fluids cloggingVIEW

Flush Flanged diaphragm Seal Pressure Gauge2018/11/26Flush Flanged diaphragm seal pressure gauge for protecting the fluids cloggingVIEW