What is Pressure Transmitter 4-20mA?

A pressure transmitter with 4-20mA output is a pressure measurement device used in factories or other places that changes pressure readings value into an electrical current signal that ranges from 4 to 20 milliamperes. This analog signal (which is different from

digital output pressure transmitters) shows the measured pressure in a way that is proportional to the actual measured value. For example, 4mA usually means no pressure (0 psi) or the lowest pressure, and 20mA means the highest pressure the pressure transducer can handle (or the highest value the user wants to use). This standardized analog output means that transducers pressure transmitters 4-20mA can work with any programmable logic controller (PLC), distributed control system (DCS), or data acquisition system in any industry,which is quite different from mechanical pressure gauge ,which normally cannot have analog outputs from these gauges.

The 4-20mA standard has become the most important part of industrial instrumentation because it has many benefits. 4-20mA Current signals don't get affected by voltage drops that happen when connection wires are very long. This is different from voltage signals pressure transducers (such as 0-5V DC). Also, the live zero at 4mA lets system operators tell the difference between a true zero reading and a broken wire or failed transmitter, which would show 0mA. This diagnostic feature makes 4-20ma pressure transducers necessary for safety-critical uses in oil and gas, water treatment, pharmaceuticals, and manufacturing plants.

Why we like to use Transducers Pressure Transmitters 4-20mA loop?

Engineers use 4-20mA pressure transducers because they have many operational and economic benefits. First, these analog pressure sensors let different factories monitor pressure (or negative pressure, differential pressure, compound pressure or vacuum pressure) in real time, which lets factory instrumentation technicians do predictive maintenance and avoid costly equipment failures and unplanned downtime. In a lot of applications for process control, keeping correct pressure or DP levels makes sure that the production line is normal, produced goods is without defects, that energy use is as low as possible, and that all rules are followed.

In today's modern factories ,many field instruments need to be able to handle harsh conditions like extreme temperatures, high rated pressure, vibration, electromagnetic interference, and corrosive media. The pressure transducer 4-20mA design solves these problems by using anti corrosive wet parts materials like stainless steel, tantalum, hastelloy alloy, hermetically sealed electronics, and industrial-grade connectors (such as IP65,IP67 or even IP68 submersible pressure transducer 4 20ma). The current loop topology also protects against noise better than voltage-based systems, so signals stay clear even in industrial settings where there is a lot of electrical noise.

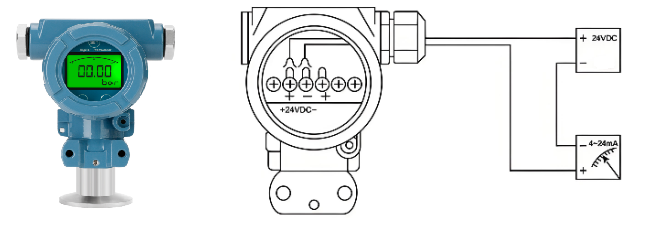

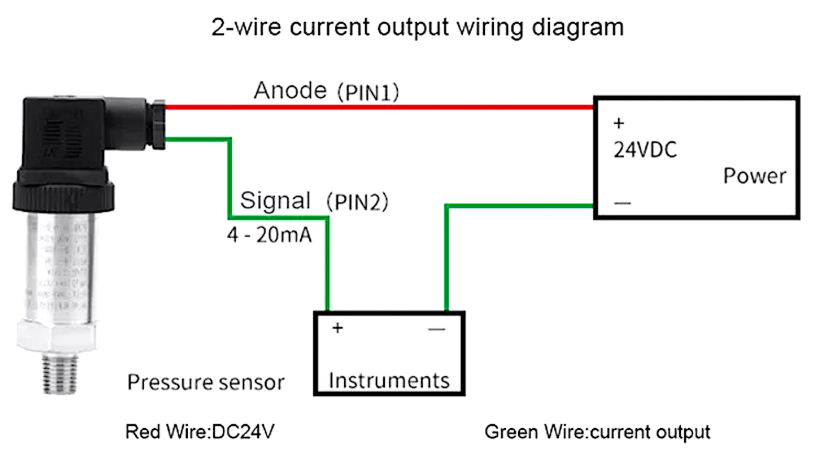

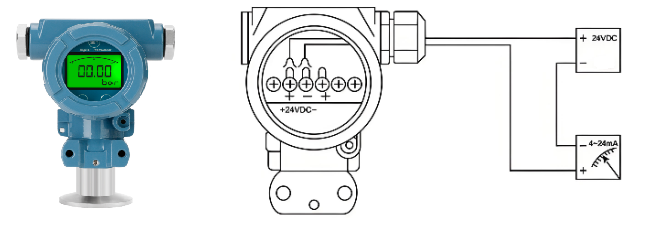

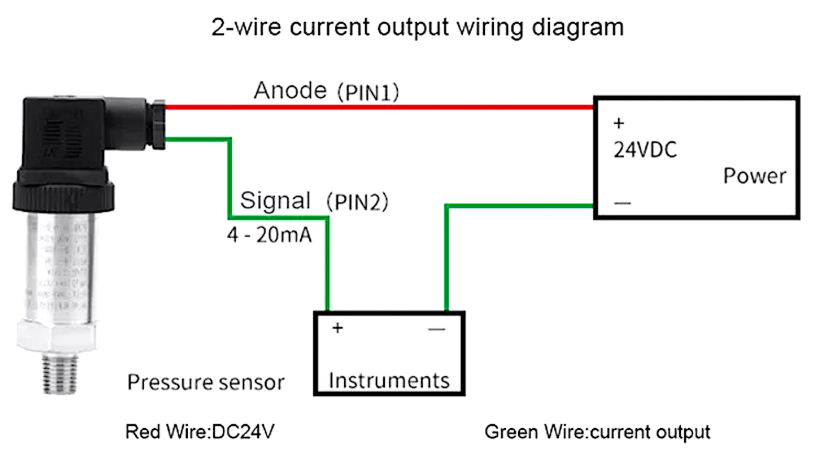

Also, because it is easy to install a 4-20ma loop pressure transducer, the time it takes to set it up and the cost of maintenance are lower. Standard two-wire pressure sensors setups only need a power supply and the device itself. The same two wires carry both power and signal. This simplicity means that installation costs are lower, wiring is less complicated than 3 wire or 4 wire field instruments, and it's also much easier to do trouble shooting when they happen.

2 wire pressure transmitter 4-20mA

2 wire pressure transmitter 4-20mA

How Pressure Transducer 4-20mA loop Devices Work

Most pressure transducer 4-20mA devices use either capacitive Monocrystalline silicon or piezoresistive sensing technologies. When pressure bends the diaphragm, piezoresistive pressure sensors use a silicon diaphragm with strain gauges that change resistance. The change in resistance is turned into a precise current 4-20mA analog output that is directly related to the pressure or DP applied. This pressure measurement technology is very accurate, usually within ±0.25% of full scale or can achieve better accuracy. It also has good temperature stability and quick response times, which makes it great for measuring dynamic pressure.

Another common idea in 4-20 mA pressure transducers is capacitive sensing technology. These pressure sensors measure how the capacitance changes between a diaphragm seal that senses pressure and a fixed electrode. Capacitive sensors are great at measuring low pressures such as 1 Kpa or 5 psi with high accuracy and stay stable reading over time. They also work better in situations where there is too much static pressure, which makes them perfect for uses where pressure spikes happen from time to time.

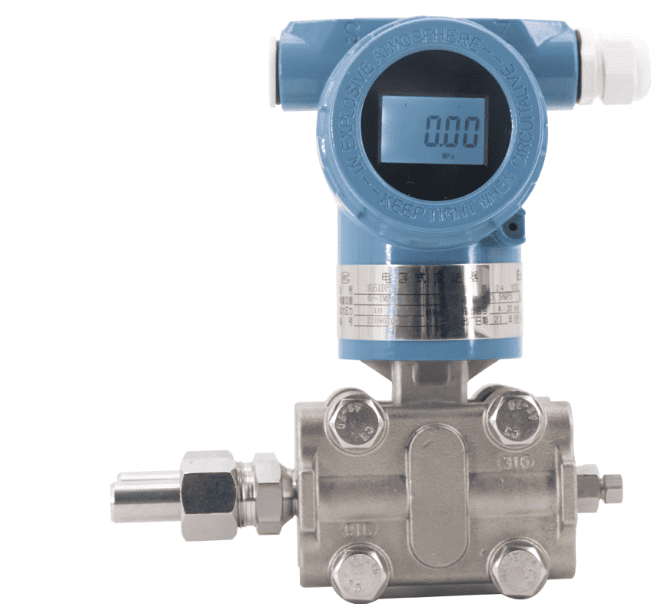

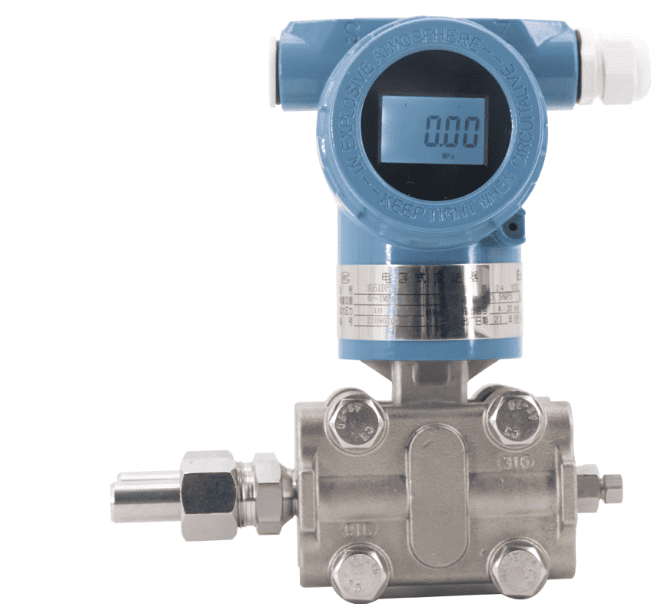

Differential pressure transmitter 4-20mA

Differential pressure transmitter 4-20mA

Differential pressure transmitter 4-20mA

Differential pressure transmitter 4-20mA outputs measure the difference in pressure between two process connections. They are often used to measure flow, check the filter, and measure the level in closed tanks. These specialized transmitters use either two sensing elements or one element with separate high- and low-pressure ports to figure out the difference and send out a 4-20mA signal that is proportional to the difference.

Advantages of Pressure Transmitter 4-20mA with Display

4-20mA Pressure Transmitter with Digital Display

4-20mA Pressure Transmitter with Digital Display

A pressure transmitter 4-20mA with display combines a traditional analog output with a local digital readout, which makes it much easier to use. The built-in display lets technicians check measurements right at the installation site without needing any extra diagnostic tools. This feature is very convenient for instrumentation technicians during commissioning, troubleshooting, and regular maintenance because it cuts down on the time it takes to find process problems.

Most of the time, these advanced DP or pressure transmitters have LCD or LED screens that show pressure values in engineering units like PSI, bar, Mpa, mmH2O, kPa, or custom pressure units. Most digital display pressure transducers have a push-button configuration that lets technicians change the damping, zero offset, and span in the field without having to unplug the device. Some new pressure transmitters 4-20mA with displays also have diagnostic features that show the minimum and maximum recorded values, the status of alarms, and error codes that speed up troubleshooting.

The electronic display of pressure transducer is especially useful in places that are hard to get to or that are too small to fit a control system display. Operators can quickly check things visually while on rounds, spotting problems right away without having to go back to the control rooms or get handheld communicators.

Common Pressure Ranges: 4–20mA 0–10 Bar and Higher for Pressure Transmitters

Different pressure ranges are needed for different industrial uses. For example, pressure transmitter 4-20mA 0-10 bar (about 0-145 PSI) is one of the most common for general industrial processes, compressed air systems, and hydraulic circuits. 10 bar pressure also works well for a lot of low-pressure steam applications, water distribution networks, and pneumatic systems. However we just take an example for 10 bar, we also provide 100 psi, 200 psi ,10Mpa or max 700 bar pressure. Most China pressure sensor manufacturers sell these brand new pressure transmitters or DP with different types of pressure connections, such as 1/2”NPT threads, G-threads, tri-clamp and flanged connections, so they can work with different piping systems.

0-100 PSI pressure transmitters (around 0-7 bar) are just as popular and common use. They work with common pressure settings in HVAC systems, pump monitoring, and compressor control. Hydraulic systems, high-pressure gas applications, and injection molding machines all use higher pressure ranges like 0-1000 PSI or 0-6000 PSI. The great thing about standardized 4-20ma pressure transducer technology is that the output signal stays the same no matter what the pressure range is. This makes it easier to integrate systems and replace instruments.

Vacuum and compound range transmitters add the ability to measure both vacuum and positive pressure, which is important for refrigeration systems, distillation columns, and vacuum packaging. These specialized pressure measurement instruments can also keep the same 4-20mA current output while measuring pressure ranges like -1 to +3 bar or -14.7 to +15 PSI or -5000 to + 5000 mmWG compound pressure detect.

Common Applications for 4-20mA loop pressure transudcers: Monitoring the pressure of water, oil, and steam

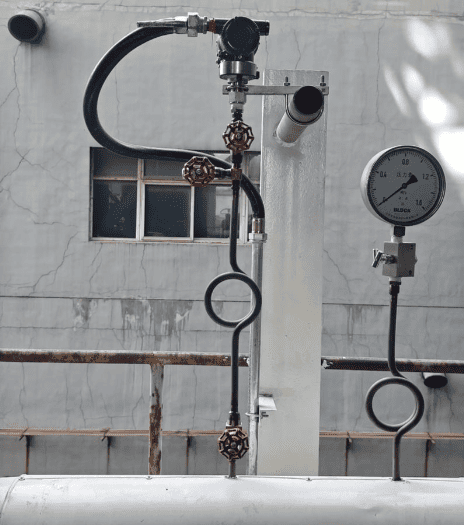

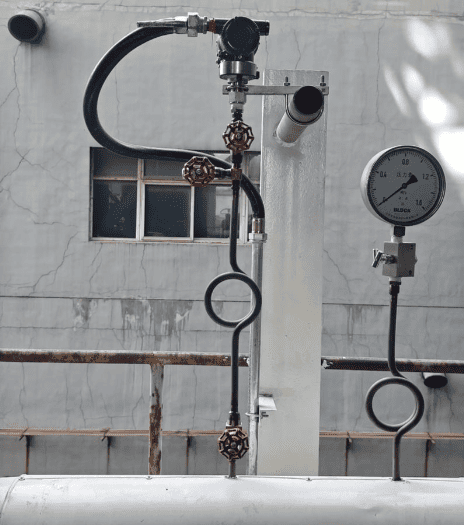

Water pressure transmitter 4-20mA

Water pressure transmitter with 4-20mA loop have many wide applications in municipal water treatment plants, distribution networks, irrigation systems, and building automation systems. These 4-20mA water pressure transducers keep an eye on the pressures in the pump discharge, the filtration system, and the distribution line to make sure that water is always delivered and that leaks are found. They manage backwash cycles, make sure the right amount of chemicals are used, and keep pumps from running dry in water treatment plants. To keep things clean while keeping an eye on clean-in-place (CIP) systems and product transfer lines, the food and beverage industries use sanitary-grade water pressure transmitters made of polished stainless steel and tri-clamp connections.

Oil pressure transmitters with 4-20mA output

4-20mA current output oil pressure transmitters are important parts of hydraulic systems, lubrication circuits, and oil processing plants. These pressure sensors protect expensive hydraulic parts in mobile equipment and manufacturing machinery by keeping an eye on system pressure and setting off alarms when it goes above safe levels or below minimum levels, which could mean a pump failure or a leak. Oil pressure transmitters made of stainless steel materials that don't break down when exposed to hydrocarbons are used in refineries and petrochemical plants to measure pressures in crude oil pipelines, distillation columns, and product storage tank farms. Oil pressure transmitters are used in marine, power generation, and automotive testing applications to make sure that the lubrication pressure is high enough to avoid serious damage to equipment.

4-20mA steam loop pressure transmitters

Steam Pressure Transmitters 4-20mA

Steam Pressure Transmitters 4-20mA

Steam pressure transmitters are very vital for making electricity, processing chemicals, sterilizing food, and heating whole neighborhoods. These high temperature pressure sensors can handle steam temperatures over 400°F (200°C) because they have special design like cooling elements, remote seals, or capillary systems that keep sensitive electronics safe from extreme heat. To keep the right operating pressures, boiler control systems use steam pressure transmitters. This keeps things safe and efficient and stops dangerous over-pressure situations. Pharmaceutical and medical device manufacturing plants use steam pressure transmitters in autoclaves and sterilization equipment. These devices make sure that the pressure is always just right, which makes sure that the sterilization cycles are effective and meet safety standards set by the government.

What to Know About the Price of a 4-20mA Pressure Transmitter

4-20mA Pressure sensor under $100

The price pressure transmitters 4-20mA can be very different depending on their features, principles, specifications, accuracy and quality levels. Different companies make entry-level pressure transmitters 4-20mA under $100. These usually have basic features and are accurate enough for non-critical uses. These affordable and cheap $100 pressure sensors are usually without electronic reading display and HART protocol, limited pressure ranges, and basic features.

Pressure or DP Transmitters have better functions, which cost between $100 and $300, are more accurate (±0.5% to ±0.25%), made of stainless steel, with digital

display for direct reading or configurations ,can work in a wider range of temperatures and static pressure rating, and are more stable over time. These transducers work well in most industrial settings where accuracy and dependability are important but extreme conditions aren't present. Premium transmitters that cost more than $300 offer better accuracy (±0.1% or better 0.075% ), certifications for hazardous areas (ATEX approved), advanced diagnostics, and building materials that can be used in corrosive or sanitary settings.

The price of the pressure transmitter 4-20mA also includes certifications and approvals. Devices that are certified for explosive atmospheres (ATEX, IECEx, CSA), sanitary applications (3-A, EHEDG), or pressure equipment directives cost more because they have to go through a lot of testing and paperwork. When looking at new pressure transmitters 4-20mA, don't just look at the initial purchase price. Instead, look at the total cost of ownership, which includes installation, calibration, and maintenance. This is because higher-quality instruments often give you better long-term value by having fewer failures and longer calibration intervals.

5 Common Questions About Pressure Transmitter 4-20mA (FAQ)

1. What is the difference between a pressure transducer and a pressure transmitter?

There are small differences between the two terms, even though they are often used interchangeably. A pressure transducer 4-20mA changes pressure into an electrical signal. A pressure transmitter, on the other hand, has extra circuitry that conditions the signal to make it stronger and more consistent at 4-20mA. Both devices do the same thing in industry: they measure pressure and give a standard current output that control systems can read. The 4-20mA standard is the industry standard for process control applications because it works with almost all PLCs and DCS systems.

2. Is it okay to use a pressure transmitter that costs less than $100 for industrial purposes?

Cheap **pressure transmitters 4-20mA under $100** can be used for monitoring that isn't very important, for school, or for short-term installations. However, for important industrial processes that need high accuracy, long-term reliability, and safety compliance, it is best to buy mid-range or high-end transmitters. Better devices are more accurate (±0.25% or better), keep their temperature better, are built to last with stainless steel housings, and have the certifications needed for dangerous areas. Think about the total cost of ownership. A cheap transmitter that breaks can cost a lot more in lost time and products than the money you saved when you bought it.

3.When I get a 4–20mA pressure transmitter with a display?

A loop pressure transmitter with digital reading display is very helpful for maintenance and trouble shooting. The built-in display lets technicians check pressure measurement values right in the field without having trouble to connect diagnostic tools or go to the control room to check the problem. The LCD display is also useful when you are commissioning sensors, doing regular inspections, or trying to check and repair something. Many transducers with displays also let you change settings in the field with the push of a key, show diagnostic information like min/max pressure values, and show alarm status or do zero trim. The local display type pressure transmitters can save a lot of time and make operations more efficient in places where it's hard to get to the control system displays, like remote installations or small spaces.

4. What range of pressure should I choose for my use?

The most common range is pressure transmitter 4-20mA 0-10 bar (0-145 PSI), which works for most industrial processes, compressed air systems, and water distribution networks. Pick a transmitter with a full-scale range that is 1.5 to 2 times your maximum expected pressure for specific uses. This will give you a little extra safety. In municipal systems, water pressure transmitters usually work in the 0–10 bar or 0–100 PSI range. In hydraulic systems, oil pressure transmitters may need to work in the 0–250 bar (0–3600 PSI) range or higher. **Steam pressure transmitters usually need to be able to work at high temperatures and have pressure ranges that match the conditions in the boiler. For low-pressure steam, this is usually 0–16 bar (0–232 PSI), and for industrial processes, it is usually higher.

5. How do I figure out what a fair price for a 4-20mA pressure transmitter is?

The price of a pressure transmitter 4-20mA depends on a number of things, such as how accurate it is, what materials it is made of, what certifications it has, and what extra features it has. Entry-level models that cost less than $100 are good for basic tasks that aren't very important. Mid-range transmitters ($100–300) have industrial-grade performance with ±0.25–0.5% accuracy, are made of stainless steel, and are stable over time, making them good for most uses. Premium transmitters (costing more than $300) have better accuracy (±0.1%), certifications for hazardous areas (ATEX, CSA), approvals for sanitary use (3-A, EHEDG), and advanced diagnostics. When looking at new pressure transmitters 4-20mA, don't just look at the initial purchase price. Instead, think about the total cost of ownership, which includes how hard they are to install, how often they need to be calibrated, how long they are expected to last, and how much downtime they might cause. Even though it costs more up front, a reliable, accurate transmitter is often worth more in the long run.

Pressure Sensor2017/04/12Low cost Pressure sensor.

Pressure Sensor2017/04/12Low cost Pressure sensor. Ceramic Pressure Sensor2025/04/02Ceramic capacitive pressure sensor.

Ceramic Pressure Sensor2025/04/02Ceramic capacitive pressure sensor. Understanding Capacitive Differential Pressure Transmitters in Industrial Automation2025/10/12Learn how capacitive pressure transmitters work, including structure, sensing principle, signal conditioning circuits, and advantages in industrial automation.VIEW

Understanding Capacitive Differential Pressure Transmitters in Industrial Automation2025/10/12Learn how capacitive pressure transmitters work, including structure, sensing principle, signal conditioning circuits, and advantages in industrial automation.VIEW Pressure Transmitter with Remote Diaphragm seals2017/04/12Remote diaphragm for corrosive or viscous fluids.

Pressure Transmitter with Remote Diaphragm seals2017/04/12Remote diaphragm for corrosive or viscous fluids. SH 308 Series Pressure Transmitter2017/04/26Piezoresistive pressure cost is low;

SH 308 Series Pressure Transmitter2017/04/26Piezoresistive pressure cost is low;  Ultrasonic level sensor with 4-20mA output2019/09/09Ultrasonic level sensor gives continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges .etc. Ultrasonic level sensor provides economical and low price cost solution fo...VIEW

Ultrasonic level sensor with 4-20mA output2019/09/09Ultrasonic level sensor gives continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges .etc. Ultrasonic level sensor provides economical and low price cost solution fo...VIEW