In salt lake chemical industries, the accurate and reliable measurement of brine flow is critical for process control and resource utilization. As industrial automation gets better, flow meters, especially electromagnetic flow meters (mag flow), have become vital device for measuring flow in brine processing systems. Brine from salt lakes usually has high conductivity, also it is very corrosive , and tends to crystallise, which makes it very hard to measure flow for some flow meter technology, such as turbine flow meter ( TUF ) or cast iron positive displacement flow meter. This article talks about how to choose flow meters for salt water brine. It focuses on the benefits of magnetic flow meters in tough conditions like very high or low temperatures, corrosive environments, and high mineral concentrations.

Saline water flow meter is needed in salt lake chemical industry

The salt lake chemical industry takes brine and turns it into useful minerals like lithium, potassium, boron, and magnesium. These brines are usually very salty, very corrosive, and have a high electrical conductivity (often more than 100 ms/cm). They also tend to crystallise when they flow. In addition, a lot of brine processes plants work in very hot or very cold places, with temperatures ranging from -30 °C to 90 °C. They also often use strong acids and alkalis in their production lines. Because of these difficult conditions, choosing the right flow measurement tools is very important for making sure that process control stays stable and lasts a long time.

Electromagnetic flow meter is a perfect solution for salt water measurement

Electromagnetic flow meters are popular in salt lake chemical applications because they can accurately measure fluids that are highly conductive and abrasive without losing pressure. They are also flow meters that do not corrode. They are great for measuring brine because they are made of materials that don't corrode, they don't get in the way, and they work with plastic or lined pipelines. This article discusses the key factors to consider when selecting a flow meter for salt water, including fluid properties, installation conditions, and application scenarios such as dosing, volume measurement, and trade metering.

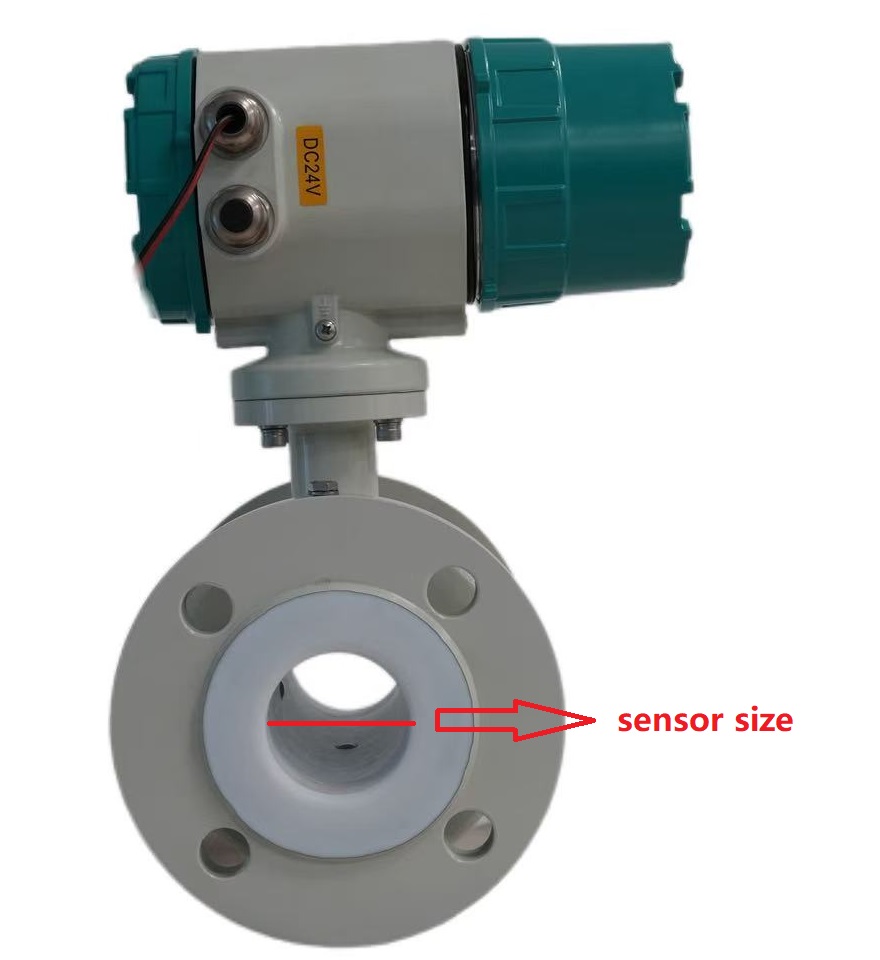

Salt water flow sensor size better the same as pipeline size

The selection of electromagnetic flow meter diameter may not necessarily be the same as the diameter, and should be based on the flow rate and velocity. However, as a raw material and intermediate liquid for salt lake chemical industry, it has the characteristics of high viscosity and low flow rate (generally 2.0-4.0m/s). Electromagnetic flow meters can be used on such pipelines with the same sensor diameter as the pipe diameter. When the flow velocity is below 1.0 m/s, an electromagnetic flow meter with an appropriate flow diameter can be selected to ensure measurement accuracy and relatively reduce investment. Below we list the salt water flow range and magnetic flow meter sensor size.

Select proper salt water flow range

Salt lake chemical industry mostly uses anti-corrosion plastic pipelines, and considering the lining of salt water flow meters, the flow rate is generally controlled at 2 m/s. For some materials that are prone to crystallization (such as sodium carbonate solution, ingredient solution: the crystallization is mainly boron magnesium complex salt), measures are taken to increase the flow rate to 3.0-4.0m/s. An increase in flow velocity will lead to an increase in flow noise, which can affect measurement accuracy due to pipeline vibration. Under the conditions for installing magnetic flow meters, shock absorbers should be installed before and after. The full range of the magnetic flow meteris greater than the expected maximum flow value, usually 1.2 times the expected maximum flow. The normal measurement flow rate is greater than 50% of the instrument's full range to ensure a certain measurement accuracy.

|

Magnetic flow meter Size(DN) |

Min salt water flow range velocity(0-0.5)m/s |

Max salt water Flow range velocity(0-10)m/s |

|

10 |

(0-2.25)L/min |

(0-45)L/min |

|

15 |

(0-5)L/min |

(0-100)L/min |

|

20 |

(0-7.5)L/min |

(0-150)L/min |

|

25 |

(0-10L)/min |

(0-200)L/min |

|

32 |

(0-20L)/min |

(0-400)L/min |

|

40 |

(0-30L)/min |

(0-600)L/min |

|

50 |

(0-3)m³/h |

(0-60)m³/h |

|

65 |

(0-6)m³/h |

(0-120)m³/h |

|

80 |

(0-9)m³/h |

(0-180)m³/h |

|

100 |

(0-12)m³/h |

(0-240)m³/h |

|

125 |

(0-21)m³/h |

|

|

150 |

(0-30)m³/h |

|

|

200 |

(0-54)m³/h |

c(0-420)m³/h |

|

250 |

(0-90)m³/h |

(0-600)m³/h |

|

300 |

(0-120)m³/h |

(0-2400)m³/h |

|

350 |

(0-165)m³/h |

(0-3300)m³/h |

|

400 |

(0-225)m³/h |

(0-4500)m³/h |

|

500 |

(0-330)m³/h |

(0-6600)m³/h |

|

600 |

(0-480)m³/h |

(0-9600)m³/h |

|

700 |

(0-660)m³/h |

(0-13200)m³/h |

|

800 |

(0-900)m³/h |

(0-18000)m³/h |

|

900 |

(0-1200)m³/h |

(0-24000)m³/h |

|

1000 |

(0-1350)m³/h |

(0-27000)m³/h |

|

1200 |

(0-2100)m³/h |

(0-42000)m³/h |

|

1400 |

(0-2700)m³/h |

(0-54000)m³/h |

|

1600 |

(0-3600)m³/h |

(0-72000)m³/h |

|

1800 |

(0-4500)m³/h |

(0-90000)m³/h |

|

2000 |

(0-5700)m³/h |

(0-114000)m³/h |

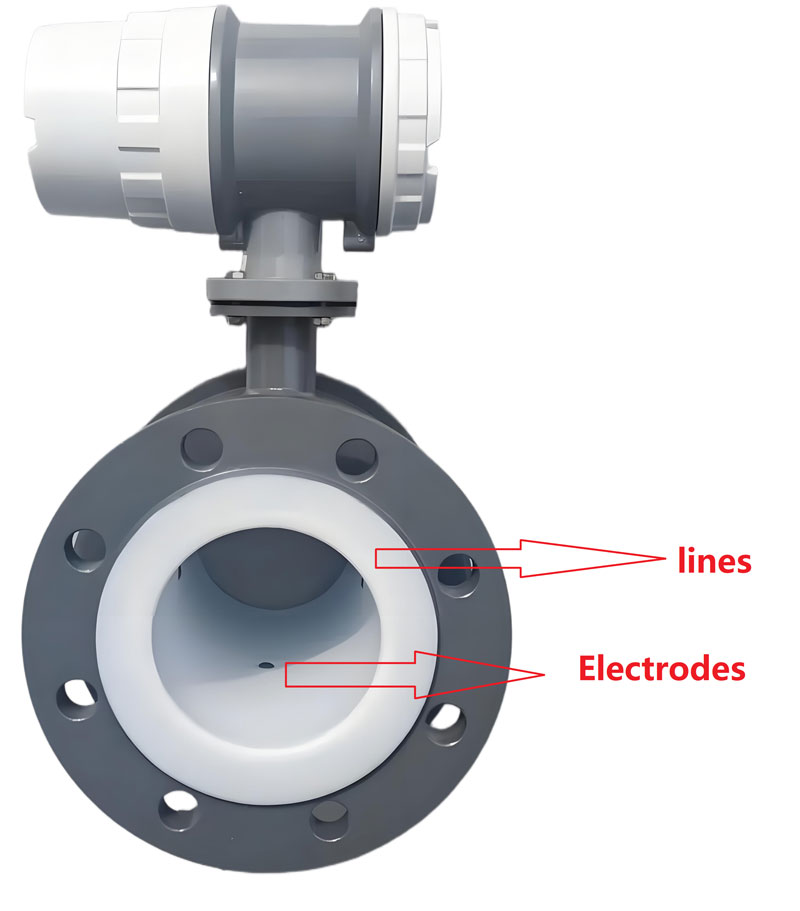

Select proper lines and electrodes for magnetic saline water flow meter

For media that do not produce crystals, clumps, or deposits that do not contaminate the electrode, standard electrodes should be used; otherwise, scraper electrodes should be used. In salt lake chemical industry, except for the use of scraper electrode electromagnetic flow meters for easily crystallized alkali solutions, ingredient solutions (crystallization of boron magnesium complex salts), washing solutions, etc., standard electrode electromagnetic flow meters are used for the rest. Due to the fact that the process pipelines in the workshop are mostly made of plastic insulation material, if a two electrode electromagnetic flow meter is selected, a grounding ring must be installed to ensure measurement accuracy. However, ordinary grounding rings are prone to corrosion, and using corrosion-resistant titanium or tantalum grounding rings is costly. Therefore, a three electrode electromagnetic flow meter is chosen to ensure measurement accuracy, reduce costs, and facilitate installation and maintenance.

|

Liquid |

Concentration (%) |

temp. ( ℃) |

Electrode |

Lining |

conductivity |

||||||

|

Name |

SS |

HC |

Ti |

Ta |

Pt |

PTFE |

PFA |

rubber |

ms/cm |

||

|

Salt lake sun drying brine |

R |

N |

B |

A |

A |

A |

A |

A |

B |

150 |

|

|

Desalination solution |

27 |

N |

B |

A |

A |

A |

A |

A |

B |

136 |

|

|

concentrated solution |

30 |

N |

B |

A |

A |

A |

A |

A |

B |

145 |

|

|

Rich lithium brine |

R |

N |

B |

A |

A |

A |

A |

A |

B |

121 |

|

|

Boron removal solution |

40 |

N |

B |

A |

A |

A |

A |

A |

B |

120 |

|

|

Conversion solution |

90 |

N |

A |

A |

A |

A |

A |

A |

N |

260 |

|

|

Wash solution |

85 |

N |

A |

A |

A |

A |

A |

A |

N |

180 |

|

|

nitric acid |

98 |

R |

N |

N |

B |

A |

A |

A |

A |

N |

50 |

|

hydrochloric acid |

31 |

R |

B |

B |

N |

A |

A |

A |

A |

B |

52 |

|

sulfuric acid |

96 |

R |

A |

A |

N |

A |

A |

A |

A |

N |

0.85 |

|

barium chloride |

30 |

50 |

N |

B |

B |

A |

A |

A |

A |

A |

16 |

A: Applicable; B: Available, short lifespan; N: Cannot be used; R: Room temperature; S: Boiling point; Sat: saturation;

Selection of magnetic flowmeter for salt water types

Remote display magnetic flow meter for salt water

The types of electromagnetic flow meters are divided into integrated and remote display types. The coldest temperature in winter can reach -30 ℃, and many electromagnetic flow meters are used outdoors. The environmental humidity for magnesium lithium separation, pressure filtration, and washing processes in lithium and boron system production is relatively high. The temperature for processes such as refinement, evaporation, and conversion can reach up to 90 ℃. Therefore, for working conditions such as high humidity, low temperature, high temperature fluids, and vibration sources, a remote display type flow meter is selected to effectively prevent the influence on the measuring components, ensure measurement accuracy, and ensure the service life of the electromagnetic flow meter. However, it should be noted that the signal cable between the electromagnetic flow meter sensor and transmitter should not be too long, and the manufacturer's dedicated cable should be used, otherwise

It will affect the measurement accuracy. For the remaining operating conditions, an integrated design is more ideal.

The actual working pressure of the salt water in the pipeline should be lower than the rated working pressure of the brine flow meter. Attention should be paid to whether there is negative pressure in the pipeline, such as in the evaporation process, where the negative pressure can reach -60KPa. Such working conditions should be communicated with the salt water flow meter manufacturer's technical personnel when ordering, and strict requirements should be made for the lining material. The actual temperature should meet the temperature requirements specified by the flow meter.

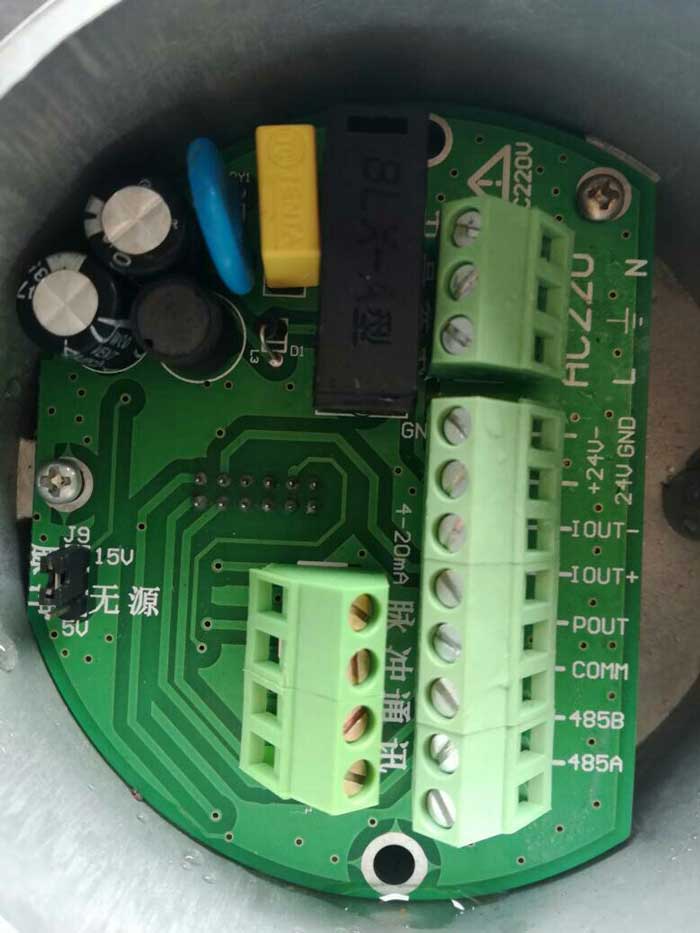

220V or 24V DC power supply should be determined when select brine flow meter

The selection of power supply for electromagnetic flow meter should be based on the flow meter itself and the on-site environment. If allowed on site, the principles of convenient power supply, safety, and easy maintenance should be followed. As a salt lake chemical enterprise, over 90% of the raw materials and process steps are in liquid phase. During operation, the humidity inside the workshop is relatively high, and there is no combustible gas generated during the entire operation. Therefore, using DC24V power supply is safer. Outdoor dry environment, choose AC220V power supply, easy to lead, easy to maintain, and reduce costs. In some explosion-proof situations, such as flow meters used in gas boiler rooms, choosing battery powered electromagnetic flow meters is ideal.

IP67 or IP65 protection level you need for saline water flow meter

The protection level of electromagnetic flow meter should be selected according to the actual situation. The sensor should be installed below the ground and IP68 should be selected when it is frequently submerged in water. For sensors installed above the ground, IP65 and IP67 should be selected. In any case, the display part of the electromagnetic flow meter cannot use water or enter water, which may cause damage to the electromagnetic flow meter. As a salt lake chemical enterprise, the humidity in the workshop is high during production, but IP65 (IP65 is anti spray type, the electromagnetic flowmeter sensor housing allows the faucet to spray water from any direction of the electromagnetic flow meter sensor, with a spray pressure of 30Kpa, a water output of 12.5L/s, and a distance of 3 meters). )The electromagnetic flow meter with protection level fully meets the requirements for on-site measurement.

Flange process connection is preferred when measuring salt water

Electromagnetic flow meters have threaded connections, flange connections, clamp types, etc. Flange connected electromagnetic flow meters are generally used in salt lake chemical industry. When selecting, it is necessary to match the flange engineering pressure and standards with the process.

Magnetic flow meters are commonly used for seawater/saltwater with diameters ranging from DN10 to DN300. The price for DN50-150 is approximately USD 400-1000

Lining materials such as PTFE/PFA /F46 have superior salt resistance, while electrode materials such as s Titanium are recommended to prevent corrosion. The housing of the magmeter can be made of carbon steel, 304 or 316 stainless steel, with 316 being more resistant to chloride ion corrosion but slightly more expensive.

In terms of communication function, the basic model supports 4-20mA/RS485/pulse; Upgrading the model to support HART and Profibus DP/PA protocols will increase the price by approximately 20-40%.

The pressure rating is usually applicable to industrial pipeline networks ranging from 1.0 to 2.5 MPa (PN10 to PN25) or even higher, such as PN40 or PN64. If a high-pressure environment (PN40 or PN64) is required, the cost will also increase.

Overall, the quotation for a regular DN50, PTFE lining, SS316 electrode, 304 shell, with 4-20mA+HART protocol, PN16 grade saltwater flowmeter is approximately USD800-900; If upgraded to 316 shell, Profibus protocol or higher pressure level, it can reach USD 1000 -1200 and above.

Electromagnetic flow meters have no moving parts, reducing maintenance requirements and achieving an accuracy of ± 0.5% or higher . They are very suitable for industrial seawater and saltwater desalination equipment,also the price is very good ,around 300-800 $.

By selecting PTFE or perfluoroalkoxy resin lining materials, as well as titanium or Hastelloy alloy electrodes, electromagnetic flowmeters can fully process saltwater. Titanium has excellent corrosion resistance to chlorides, hypochlorites, and seawater, while nickel alloys provide better corrosion resistance than stainless steel, especially in low concentration acid and saltwater applications. If the environment is also corrosive, stainless steel shell material can even be chosen.

The following types of flow meters can also be considered in saltwater applications:

Ultrasonic flowmeter: most suitable for marine fuel systems, offshore oil and gas platforms, and coastal water monitoring, providing non-invasive installation options

Rotameter: variable area flowmeters can be made of PTFE lining material and can fully measure saltwater with corrosive liquids. Moreover, silverinstruments.com not only has a rotor flowmeter that can indicate instantaneous flow rate, but also a flow accumulator that displays the total amount of saltwater.

It is not recommended to use a vortex flowmeter to measure saltwater, as the liquid receiving material of the vortex flowmeter is stainless steel 304 or 316, which will still be corroded by saltwater over time.

With the maturity of the domestic flow metering instrument industry, salt lake chemical enterprises such as lithium carbonate, boric acid, and potassium fertilizer will also integrate with the domestic market. Electromagnetic flow meters, as an important industrial flow measurement instrument, are particularly important to play their role in DCS control. Reasonable and correct selection is particularly important in order to provide accurate measurement data to enterprises, reduce labor costs, and improve production efficiency.

With the maturity of the domestic flow metering instrument industry, salt lake chemical enterprises such as lithium carbonate, boric acid, and potassium fertilizer will also integrate with the domestic market. Electromagnetic flow meters, as an important industrial flow measurement instrument, are particularly important to play their role in DCS control. Reasonable and correct selection is particularly important in order to provide accurate measurement data to enterprises, reduce labor costs, and improve production efficiency.

Brine flow meter2019/08/15Electromagnetic flow meter can monitor aggressive liquid such as salt brine. Silver Automation Instruments offer mag meter for the brine flow measurement solution at low price cost .Magnetic flow mete...VIEW

Brine flow meter2019/08/15Electromagnetic flow meter can monitor aggressive liquid such as salt brine. Silver Automation Instruments offer mag meter for the brine flow measurement solution at low price cost .Magnetic flow mete...VIEW Stainless steel flow meter2019/05/22Stainless steel flow meter can be used in harsh environment for corrosive fluids or gas measurement. It can be used in food or pharmaceutical industry for chemical solution, acid or alkali solution, a...VIEW

Stainless steel flow meter2019/05/22Stainless steel flow meter can be used in harsh environment for corrosive fluids or gas measurement. It can be used in food or pharmaceutical industry for chemical solution, acid or alkali solution, a...VIEW Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.VIEW

Electromagnetic Flowmeter2017/04/12Buy Quality Electromagnetic Flow meter from China manufacture in low price and fast delivery time. Get the Mag meter Price cost now from SILVER AUTOMATION INSTRUMENTS.VIEW Chemical flow meter low flow2019/07/23We supply chemical flow meter working at low flow rate, no matter it is corrosive or non-aggressive liquid, conductive or non-conductive liquid, viscous or non-viscous chemical solution, we all have p...VIEW

Chemical flow meter low flow2019/07/23We supply chemical flow meter working at low flow rate, no matter it is corrosive or non-aggressive liquid, conductive or non-conductive liquid, viscous or non-viscous chemical solution, we all have p...VIEW Low flow rotameter2019/06/06Metal tube rotameter can work on the water low flow min to 1.6 Liter/hour, it can be used to detect fluids micro flow rate. Metal tube variable area flowmeter is one of the oldest flow measurement tec...VIEW

Low flow rotameter2019/06/06Metal tube rotameter can work on the water low flow min to 1.6 Liter/hour, it can be used to detect fluids micro flow rate. Metal tube variable area flowmeter is one of the oldest flow measurement tec...VIEW Turbine Flow meter for corrosive liquid2023/03/17What is turbine flow meter for corrosive liquid?A turbine flow meter is a type of flow meter that measures the rate of fluid flow by utilizing a turbine wheel that rotates as the fluid passes through ...VIEW

Turbine Flow meter for corrosive liquid2023/03/17What is turbine flow meter for corrosive liquid?A turbine flow meter is a type of flow meter that measures the rate of fluid flow by utilizing a turbine wheel that rotates as the fluid passes through ...VIEW