Revolutionizing Biogas Flow Measurement: Unveiling Cutting-Edge Technologies

The significance of biogas in environmental sustainability and resource conservation has prompted extensive research and development efforts across the globe. As countries invest substantial resources to harness the potential of biogas, the importance of accurate biogas flow measurement emerges as a critical aspect of biogas utilization. This article explores the pivotal role of biogas flow measurement and delves into advanced technologies that have reshaped the landscape, including thermal mass flow meters, gas turbine flow meter, vortex shedding flowmeters, rotameters, and ultrasonic flow meters.

Understanding the Significance of Biogas

Biogas stands as a testament to the synergy between environmental protection and resource optimization. It’s recycling not only benefits nations and their inhabitants but also safeguards the planet by curbing pollution and conserving valuable resources. The pursuit of biogas recycling technology has galvanized nations, with biogas power generation emerging as a sophisticated field mastered by only a select few countries. This technology forms a cornerstone in the holistic approach to sustainable development.

Biogas Flow Measurement: A Vital Challenge

The efficient utilization of biogas hinges on accurate flow measurement, presenting a challenge that demands innovative solutions. Traditional gas flowmeters have proven inadequate for biogas flow measurement applications. However, with the maturation of thermal gas mass flowmeter technology, an increasing number of biogas power generation and recovery companies are embracing this advancement. The successful application of thermal mass flow meters has triumphantly addressed a long-standing predicament in the industry. A comparative analysis with other gas flow sensors highlights the prowess of thermal mass flow meters.

Exploring Flow Meter Technologies for Biogas Measurement

Thermal Mass Flow Meter for biogas flow measurement: The Epitome of Precision

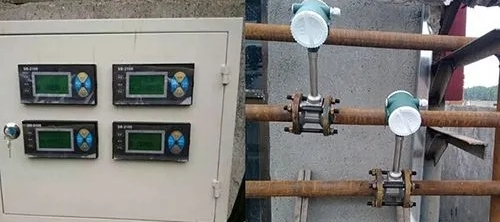

The unparalleled advantages of thermal mass flow meters position them as a preferred choice for biogas flow measurement. With an impressive range ratio of up to 1000:1, sensitivity to low flow, immunity to temperature and pressure fluctuations, negligible pressure loss, and the capability to handle large diameters and small flows, these meters offer unparalleled accuracy and efficiency. Their ease of use, whether in plug-in biogas flow meter or in-line biogas flowmeter configurations, further solidifies their role in advancing biogas flow measurement.

Vortex Shedding Flowmeter for biogas flow measurement: Precision Sans Moving Parts

Vortex shedding flowmeters emerge as a promising solution for biogas flow measurement, boasting attributes like accuracy, minimal pressure loss, and absence of moving parts. These sensors remain detached from the fluid being measured, ensuring that output signals remain unaffected by temperature, pressure, density, composition, and viscosity variations. Installation is relatively straightforward, with options for plug-in and duct types. However, challenges such as limited ratio and susceptibility to pipeline vibrations should be considered, especially when seeking precision and stability.

Rotameter: Simplicity in Display and Installation

The rotameter offers simplicity in biogas flow measurement, featuring local displays and requiring no power supply. Available in glass tube and metal tube variants, it offers flexible display options and rotameter flow transmitters such as HART, standard current 4-20mA signal, and PROFIBUS. While installation is convenient, considerations must be made for fluid flow direction and the risk of blockages. Its limitations include range ratio constraints, significant pressure loss, vulnerability to dirt accumulation, and complex maintenance procedures.

Ultrasonic Flow Meter (Gas): Versatility in Measurement

Ultrasonic flow meters stand out for their versatility, capable of measuring gases, liquids, and steam without pressure loss. In the context of biogas flow measurement, these meters offer independence from fluid properties such as temperature, pressure, viscosity, and composition. While installation and maintenance may pose challenges, the ability to measure dirt, corrosive gases, and multi-component gases underscores their adaptability to diverse applications.

Embracing the Future: Why Thermal Gas Flow Meters for Biogas flow measurement ?

Thermal gas mass flow meters emerge as champions in gas measurement, particularly in low-pressure scenarios with complex gas compositions. Their advantages include energy efficiency, minimal pressure loss, and a wide range ratio, making them an ideal choice for biogas flow measurement. By providing precise and accurate metering, thermal gas mass flow meters empower industries to optimize biogas utilization and contribute to a sustainable future.

Gas Turbine Flow Meter for Biogas: Advantages and Disadvantages

Gas turbine flow meters have gained prominence as a versatile solution for measuring biogas flow rates, offering unique advantages along with certain limitations. These gas flowmeters utilize the kinetic energy of the flowing biogas to drive a turbine, generating accurate measurements. The advantages of gas turbine flow meters include their wide measuring range, high accuracy, and suitability for various biogas compositions. They are also less affected by changes in temperature and pressure.

However, gas turbine flow meters may face limitations due to their moving parts, making them sensitive to impurities and requiring regular maintenance. Moreover, these meters can be affected by flow disturbances and are better suited for clean biogas. Overall, the gas turbine flow meter stands as an efficient tool for biogas measurement, offering precise readings while necessitating careful consideration of operational conditions and maintenance protocols.

Conclusion

The evolution of biogas flow measurement has witnessed remarkable advancements in technology, culminating in thermal gas mass flow meters as a transformative solution. The intersection of accuracy, efficiency, and environmental consciousness has led to the widespread adoption of these flow meters across industries and applications. As the world navigates the path towards sustainable development, the role of biogas in resource conservation and environmental preservation is indisputable, further solidifying the importance of accurate flow measurement technologies in shaping a greener tomorrow.

Thermal mass flow meter2019/06/14Low cost flow meter for gas and air

Thermal mass flow meter2019/06/14Low cost flow meter for gas and air Metal tube Rotameter2019/06/13Variable area flow meter

Metal tube Rotameter2019/06/13Variable area flow meter Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install.

Insertion type thermal mass flow sensor2019/06/14Insertion gas flow sensor and easy install. Vortex Flow Meter2017/04/12Vortex Flow meter is for clean liquid, gas and steam flow measurement. Contact us to choose proper type flow sensor and get the competitive quotation.VIEW

Vortex Flow Meter2017/04/12Vortex Flow meter is for clean liquid, gas and steam flow measurement. Contact us to choose proper type flow sensor and get the competitive quotation.VIEW In-line type thermal dispersion flow meter2019/06/14Gas mass flow measurement.

In-line type thermal dispersion flow meter2019/06/14Gas mass flow measurement. Gas Turbine Flow Meter2017/04/12Robust Gas flow meter for natural gas,LPG,biogas flow measurement.Inquiry Gas TUF Flowmeter price with EVC directly from China manufacture.VIEW

Gas Turbine Flow Meter2017/04/12Robust Gas flow meter for natural gas,LPG,biogas flow measurement.Inquiry Gas TUF Flowmeter price with EVC directly from China manufacture.VIEW