In today's industrial process control, custody transfer and billing systems being able to accurately measure fluid mass flow is very important for keeping things running smoothly, enabling accurate batching in manufacturing and fair billing in trade metering. Mass flow meters are now essential measurement instruments in many fields because they are more accurate and reliable than volumetric flow measurement devices (such as turbine flow meter, positive displacement flow meter ,magnetic flow meter and so on) . This detailed guide talks about what mass flow meters are, what they're good for, the different types, and the most important uses for them.

A mass flow meter is a very accurate tool that measures the mass flow rate of fluids moving through a pipeline. Mass flow meters, on the other hand, give direct fluids mass measurements in flow units like kg, ton or pounds that don't change with temperature, pressure, density, or viscosity. However volumetric flow meters measure fluids volume (flow units like m3/h , CFM or GPM) . Because of this ability, they are necessary for situations that need high accuracy and consistency.

There are many physical principles that mass flow meters work on, but the Coriolis effect is the most common and also the best accuracy one. When fluid moves through two vibrating measurement sensor tubes, it causes phase shifts or frequency changes that are proportional to the mass flow rate. The Coriolis mass flow transmitter can accurately calculate the mass flow with great accuracy by noticing these changes.

In numeral industrial actual applications, mass flow measurement is much better than volumetric measurement for a number of reasons:

Coriolis mass flow meters usually measure with an accuracy of ±0.1% to ±0.2%, which is much better than traditional volumetric flow meters (For example, rotameters can only have 1.0~1.5% accuracy). This high accuracy is very important for custody transfer, batching, and quality control, where even small mistakes or inaccurate measurements can have negative effects.

Changes in fluid’s temperature and pressure don't affect Coriolis sensor measurement result, so there is no need to do compensation or correction calculations (For example EVC gas turbine flow meter). This feature is especially useful in some applications where the operating conditions like pressure or temperature change often in gas flow measurement, since volumetric measurements would need complicated corrections that add more uncertainty.

A lot of industrial processes need mass data instead of volume data. Mass is important for chemical reactions, mixing materials, and figuring out how much energy is needed. Mass flow meters give you this information directly, which decrease conversion errors and makes process control easier. For example, if the flow rate of nitrogen calculated from the gas turbine meter is 20 CFM, it is difficult to obtain an accurate density value to convert it to kg/h.

Modern mass flow meters can measure more than one parameter (mass flow unit) at a time, such as density, concentration, brix and temperature. This multi-functionality means fewer filed instruments are needed, which lowers installation costs and makes the whole system easier to use while also making measurements more reliable.

Mass flow meters can work with a lot of different fluids, like liquids, gases, slurries; also it can handle tough fluids applications, like ultra-low temperature oxygen measurement, ultra-high pressure nitrogen measurement, ultra-viscous asphalt or crude oil measurement, and highly abrasive mining slurry measurement.

there are two main types of mass flow meters based on how they work:

Direct mass flow meters measure the mass flow rate without needing to do any extra math or conversions:

Coriolis meters are the most common type of direct mass flow meter. They use the Coriolis effect principle. When fluid moves through one or more vibrating tubes, the Coriolis forces cause changes in the phase or frequency that can be measured. These meters are very accurate (usually ±0.1% or better), can measure both liquids and gases, and can also measure density at the same time. They are perfect for transferring custody, precise batching, and measuring fluids with high value.

Thermal meters use the principles of heat transfer to find the mass flow rate by measuring the heat that flowing fluid carries away. They are for measuring gas and are especially popular in semiconductor manufacturing, monitoring natural gas, and compressed air systems. These meters are cheap to use for gas and don't need much maintenance.

Indirect mass flow meters calculate the mass flow by measuring both volume flow and density:

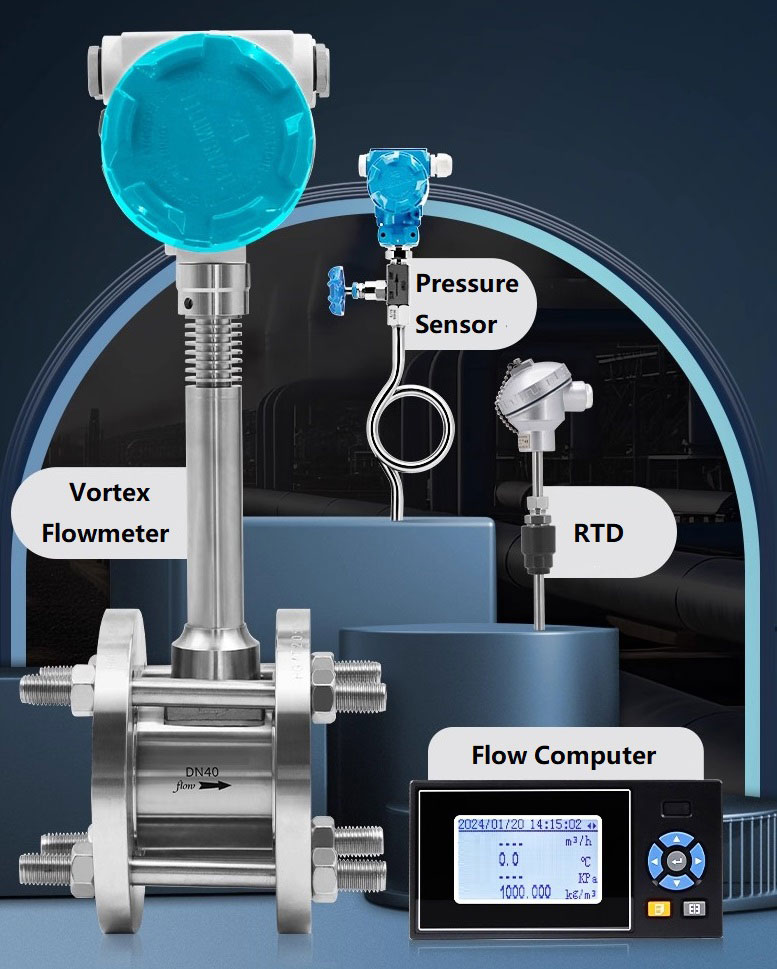

Indirect Steam mass flow measurement by vortex flow meter

This method uses a separate density meter and a volumetric flow meter, like a turbine, vortex, or electromagnetic meter. To find the mass flow, multiply the volume flow by the density. This solution may not be as accurate as direct methods, but it can be cheaper for some uses.

Differential pressure flow meter

You can improve traditional DP flow meters (like orifice plates, V-cone, annular and venturi tubes) by adding temperature sensor RTD and pressure sensor to realize compensation to get estimates of mass flow. These systems are well-known and have very long history, but they usually aren't as accurate as direct mass flow meters. However, it still has wide applications, such as high-pressure natural gas measurement and superheated steam flow measurement.

Indirect mass flow meters are much cheaper, but they are usually less accurate and reliable than direct measurement methods. They also need more maintenance because they have more sensors to get the result.

Coriolis mass flow meters are used in fields that need exact batching and strict process control. In the chemical industry, they keep an eye on the feedstock that goes into reactors to make sure that the right amounts of different chemicals are involved in reactions. In the oil and gas industry, they are used to measure crude oil, natural gas, LPG for trading purpose. The food and drug industries also depend on them to carefully control the addition of important or expensive ingredients like sugars, flavourings, and active ingredients.

Coriolis mass flowmeter is great at dealing with complicated and tough fluids. It accurately measures non-Newtonian fluids, liquids with bubbles, and fluids with extremely high viscosity, like crude oil, resin, molasses or chocolate paste. These are the kinds of fluids that other flow meters often cannot handle. Also, it works very well in high-pressure and high-temperature situations, like measuring the flow of wax, cryogenic propane, drilling mud, liquid sulfur and so on. Mass flow sensor design, which has no dead zones and no moving parts, makes it easy to clean and meets strict sanitary standards for hygienic uses like transporting dairy or biopharmaceuticals through pipelines.

Coriolis mass flow meters measure more than just mass flow. They also measure fluid density and temperature. This added feature greatly increases their range of uses, allowing for indirect measurements of important factors like liquid concentration, alcohol purity, sugar content (Brix), or sulphuric acid concentration, which means you don't need as many separate sensors.

Coriolis Mass Flow Meter for the Fluorochemical and Specialty Gas Industry in Southeast Asia2025/10/17What are the flow meters for the fluorochemical and specialty gas industry? Learn how Coriolis mass flow meters deliver accurate, corrosion-resistant, and cryogenic-capable measurement for liquefied gases and dense chemicals in Southeast Asia’s growing flVIEW

Coriolis Mass Flow Meter for the Fluorochemical and Specialty Gas Industry in Southeast Asia2025/10/17What are the flow meters for the fluorochemical and specialty gas industry? Learn how Coriolis mass flow meters deliver accurate, corrosion-resistant, and cryogenic-capable measurement for liquefied gases and dense chemicals in Southeast Asia’s growing flVIEW Thermal mass flow meters2025/04/30Thermal gas flow meters with factory pricing from China – accurate, stable, and ideal for air, NG, CO₂, N₂, biogas, LPG/CNG.VIEW

Thermal mass flow meters2025/04/30Thermal gas flow meters with factory pricing from China – accurate, stable, and ideal for air, NG, CO₂, N₂, biogas, LPG/CNG.VIEW Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Thermal Mass Flow Meter2017/05/27Low cost gas flow meter.

Thermal Mass Flow Meter2017/05/27Low cost gas flow meter. Steam Mass Flow Meter2023/04/06Vortex flow meters to measure steam mass flow rate and have digital display to show steam total mass flow . Built-in temperature and pressure compensation .VIEW

Steam Mass Flow Meter2023/04/06Vortex flow meters to measure steam mass flow rate and have digital display to show steam total mass flow . Built-in temperature and pressure compensation .VIEW Four Ways To Measure Steam Flow2020/12/10People have been showing more interest in energy production and use for the last few years. The increasing price of crude oil has affected all areas of the economy and has led to increased fuel prices...VIEW

Four Ways To Measure Steam Flow2020/12/10People have been showing more interest in energy production and use for the last few years. The increasing price of crude oil has affected all areas of the economy and has led to increased fuel prices...VIEW