A mass flow meter is a device used to measure the mass flow rate of a fluid. It is commonly employed in various industrial applications where accurate measurement of fluid flow is essential. traditional mass flow meters that measure volumetric flow (such as liters per minute) , fluids temperature and pressure to calculate the fluids mass flow, Coriolis mass flow meters directly measure the mass of the fluid passing through the system (such as kilograms per second or ton/h ).

There are different types of mass flow meters, including:

-

1. Coriolis Flow Meters: These meters utilize the Coriolis effect, which is the deflection of a mass moving in a rotating system. The fluid flows through a vibrating tube, and the Coriolis forces acting on the fluid cause a phase shift in the tube's vibration. This phase shift is directly proportional to the mass flow rate.

-

2. Thermal Mass Flow Meters: These meters measure the heat transfer between a heated sensor and the fluid. As the fluid flows past the heated sensor, it carries away some of the heat, and the temperature difference between the sensor and the fluid is used to determine the mass flow rate.

-

3. Differential Pressure Flow Meters: These meters measure the pressure drop across a constriction or obstruction in the flow path. By knowing the pressure drop and the geometry of the flow path, also gas ,air or steam temperature and pressure to calculate fluids density , then mass flow rate can be calculated.

-

4. Vortex flow meters: Vortex flow meters are primarily used to measure volumetric flow rates, not mass flow rates. However, by incorporating additional sensors and considering the fluid's density, it is possible to estimate the mass flow using a vortex flow meter, it is used a lot to measure steam mass flow.

Mass flow meters are often used in industries such as oil and gas, chemical processing, food and beverage, pharmaceuticals, and environmental monitoring. They provide accurate and reliable measurements of mass flow, which is crucial for process control, efficiency optimization, and quality assurance in various applications. Here we list top 10 mass flowmeters which are requested by users in year 2023.

A thermal mass flow meter is a device that measures the flow rate of a gas, including air, by measuring the heat transfer between a heated sensor and the fluid. In an air flow meter, the meter is inserted or installed into a pipe or duct, and the air flows past the heated sensor.

As air flows past the heated sensor, the sensor loses heat to the air, and the rate of heat loss is proportional to the mass flow rate of the air. The meter measures the temperature difference between the heated sensor and the air, and uses this information to calculate the mass flow rate of the air, normal request air mass flow meter is 2 inch air mass flow meter, 3” air mass flow meter, 4 inch mass flow meter for air, 8 inch air flow meter, 10 inch mass flow meter for air, 12 inch mass flow meter.,etc.

Thermal mass flow meters are commonly used in HVAC systems, industrial processes, and other applications where accurate measurement of air flow is important, it can be compressed air mass flow meter, duct Air mass flow meter, blower air mass flow measurement, and flue air mass flow meter. They offer several advantages over other types of flow meters, including high accuracy, low pressure drop, low price cost on large size, and no moving parts.

A biogas mass flow meter is a device that measures the flow rate of biogas, which is a mixture of gases produced by the breakdown of organic matter in the absence of oxygen. Biogas typically consists of methane, carbon dioxide, and small amounts of other gases such as hydrogen, nitrogen, and oxygen.

To measure the flow rate of biogas, a mass flow meter is typically used. The meter works by measuring the mass of gas passing through the meter per unit time. This can be done using several different technologies, including thermal mass flow meters, Coriolis flow meters, and gas turbine flow flow meters. Thermal mass flow meters work by measuring the heat transfer between a heated sensor and the biogas as it flows past, the flow unit by measure biogas is Nm3/h or kg/h .etc.

Biogas mass flow meters are commonly used in biogas production facilities to measure the amount of gas produced and to control the process. They are also used in other applications, such as in landfill sites, wastewater treatment plants, and in the agricultural sector where biogas is used for power generation or as a fuel.

An insertion mass flow meter is a type of flow meter that is inserted into a pipe or duct to measure the flow rate of a fluid, typically a gas. The meter works by measuring the velocity of the fluid at a specific point in the pipe or duct and using this information to calculate the mass flow rate.

Insertion mass flow meters can be thermal Insertion Flow Meters: These meters use a heated sensor to measure the heat transfer between the sensor and the fluid as it flows past. The rate of heat transfer is proportional to the mass flow rate of the fluid.

Insertion mass flow meters are commonly used in industrial applications where it is not feasible to install a full-size flow meter. They can be inserted into a pipe or duct through a small hole, minimizing the need for extensive modifications to the piping system. They are also less expensive than full-size flow meters and can be used to measure flow rates in large ducts and pipes, insertion mass flow meter can be mass flow meter for air, mass flow meter for biogas or mass flow meter for natural gas and so on. Insertion mass flow meter size starts from 3” pipelines.

A CO2 mass flow meter is a type of flow meter that measures the flow rate of carbon dioxide gas (CO2) in a system. CO2 mass flow meters are commonly used in applications where accurate measurement of CO2 flow rates is important, such as in HVAC systems, greenhouses, and industrial processes.

There are several types of CO2 mass flow meters available, including thermal mass flow meters, vortex flow meters, and Coriolis flow meters. Each type of meter works differently, but they all measure the flow rate of CO2 by measuring the velocity of the gas and the density of the gas.

Thermal mass flow meters work by heating a sensor and measuring the heat transfer between the sensor and the gas as it flows past. The rate of heat transfer is proportional to the mass flow rate of the gas. Vortex flow meters work by measuring the frequency of vortices shed by a bluff body inserted into the gas flow path. The frequency of the vortices is proportional to the flow rate of the gas. Coriolis flow meters work by measuring the change in the Coriolis force on a vibrating tube as gas flows through it. The change in force is proportional to the mass flow rate of the gas; however cryogenic liquid CO2 mass flow meter can be realized by Coriolis mass flow meter.

CO2 mass flow meters are often used in conjunction with controllers and sensors to maintain a specific CO2 concentration in a system. For example, in a greenhouse, CO2 flow can be adjusted to optimize plant growth, and in an HVAC system, CO2 flow can be adjusted to ensure a comfortable and healthy indoor environment.

A liquid mass flow meter is a type of flow meter used to measure the flow rate of liquid through a pipe or other conduit. Liquid mass flow meters are used in a wide range of applications, including chemical processing, food and beverage production, and wastewater treatment.

There are several types of liquid mass flow meters, including:

Coriolis Flow Meters: These meters measure the mass flow rate of the liquid by measuring the deflection of a vibrating tube as the liquid flows through it, it is a kind of flow sensor directly measure fluids mass flow.

Liquid mass flow meters are typically used in applications where precise measurement of liquid flow rates is important, such as in chemical processing, where accurate dosing of chemicals is critical for proper reaction rates. They can also be used in industrial applications to monitor liquid flow rates for process control and optimization.

Applications to need liquid mass flow meter

Liquid mass flow meters are used in various applications where precise measurement of liquid flow rates is important. Some common applications of liquid mass flow meters include:

Chemical Processing: Chemical processes require accurate dosing of chemicals and other materials, which is achieved through precise control of liquid flow rates.

Food and Beverage Production: Liquid mass flow meters are used in the food and beverage industry to accurately measure the flow of ingredients, such as sugar or water, into the production process.

Oil and Gas Production: In the oil and gas industry, liquid mass flow meters are used to measure the flow of crude oil, water, and other liquids in production and transportation systems.

Wastewater Treatment: Accurate measurement of liquid flow rates is important in wastewater treatment systems to ensure that the right amount of chemicals are added at the right time to maintain optimal treatment conditions.

Pharmaceutical Production: In pharmaceutical production, liquid mass flow meters are used to measure and control the flow of ingredients in the manufacturing process, which is critical for ensuring the quality and consistency of the final product.

These are just a few examples of the many applications where liquid mass flow meters are used to measure liquid flow rates.

A steam mass flow meter is a type of flow meter used to measure the flow rate of steam, which is a vaporized form of water, through a pipe or other conduit. Steam mass flow meters are used in a wide range of applications, including power generation, chemical processing, and industrial heating.

There are several types of steam mass flow meters, including:

Differential Pressure Flow Meters: These meters measure the pressure drop across a constriction in the steam flow path, which is proportional to the flow rate.

Vortex Flow Meters: These meters detect the vortices that form downstream of a bluff body in the steam flow path. The frequency of the vortices is proportional to the flow rate of the steam, by adding temperature and pressure sensor, we can realize saturated steam or overheated steam mass flow measurement.

Steam mass flow meters are typically used in applications where precise measurement of steam flow rates is important, such as in power generation, where accurate measurement of steam flow is critical for the efficient operation of turbines and other equipment. They can also be used in industrial applications to monitor steam flow rates for process control and optimization.

A fuel oil mass flow meter is a type of flow meter used to measure the flow rate of fuel oil, which is a heavy, viscous liquid fuel, through a pipe or other conduit. Fuel oil mass flow meters are used in a wide range of applications, including power generation, marine, and industrial heating.

Coriolis Flow Meters are flow meters to measure the mass flow rate of the fuel oil by measuring the deflection of a vibrating tube as the fuel oil flows through it. Coriolis mass flow meters are digital fuel oil mass flow meters with 4-20mA, pulse, and frequency outputs. It is also with MODBUS RTU or HART protocol.Normal request fuel oil mass flow meters are 3/4” fuel mass flow emter, 1 inch mass flow meter for fuel, 2 inch, 3” ,4 inch mass flow meter for fuel oil, 6 inch or 8 inch Coriolis fuel flow meter.

Fuel oil mass flow meters are typically used in applications where accurate measurement of fuel oil flow rates is important, such as in power generation, where precise measurement of fuel oil flow rates is critical for the efficient operation of boilers and other equipment. They can also be used in marine applications to monitor fuel consumption and optimize engine performance, as well as in industrial heating applications to measure and control the flow of fuel oil to burners and other equipment.

An N2 mass flow meter is a type of flow meter used to measure the flow rate of nitrogen gas (N2) through a pipe or other conduit. Nitrogen gas is commonly used in industrial applications, such as in the production of electronics, in welding and cutting processes, and in food and beverage packaging.

There are several types of N2 mass flow meters, including:

Thermal Mass Flow Meters: These meters measure the flow rate of nitrogen gas by measuring the amount of heat transferred from a heated element to the gas. The heat transfer rate is proportional to the flow rate of the nitrogen gas, it can be inline N2 gas flow meter or insertion N2 gas flow meter.

Coriolis Flow Meters: These meters measure the mass flow rate of the nitrogen gas by measuring the deflection of a vibrating tube as the gas flows through it. Liquid nitrogen is liquid nitrogen gas. Under normal pressure, the temperature of liquid nitrogen is -196 ℃, and LN2 is an ultra-low temperature mass flow meter. Due to the extremely low temperature, there are very few suitable flow meters to measure. The mass flow meter can measure liquid nitrogen mass flow to -200 ℃, which is completely capable of measuring, It is cryogenic flow meter.

N2 mass flow meters are typically used in applications where precise measurement of nitrogen gas flow rates is important, such as in the production of electronics, where nitrogen gas is used to create a clean environment, or in food and beverage packaging, where nitrogen gas is used to preserve the contents of the package. They can also be used in industrial processes that require the precise control of nitrogen gas flow rates, such as in welding and cutting processes.

A high temperature mass flow meter is a type of flow meter designed to measure the flow rate of fluids, gases, or steam at high temperatures. These flow meters are typically used in industrial applications where high temperatures are encountered, such as in power generation, chemical processing, and metal refining.

There are several types of high temperature mass flow meters, including:

Thermal Mass Flow Meters: These meters use heat transfer principles to measure the flow rate of fluids or gases. They typically use a thermal sensor and a heater to measure the heat transfer from the fluid or gas to the sensor. They can be designed to operate at temperatures up to 300°C,it can measure Flue Gas, exhaust gas, exhaust air,hot air.,etc

Vortex Flow Meters: These meters use the principle of vortex shedding to measure the flow rate of fluids or gases. They can be designed to operate at temperatures up to 300°C , Vortex flowmeter is a volumetric flowmeter that calculates the mass flow rate of the medium through temperature and pressure compensation when measuring steam and gas.

Coriolis effect mass flow meter, The maximum temperature of the medium that can be measured by a Coriolis mass flow meter is 350 degrees Celsius. High temperature flow meters can be used to measure asphalt, liquid metal at near 350 Celsius, grease, etc. High temperature mass flow meters can be equipped with insulation jackets. The accuracy of the high-temperature mass flowmeter is very high, reaching around 0.2%.

High temperature mass flow meters are typically used in industrial applications where accurate measurement of fluid or gas flow rates at high temperatures is critical for process control and optimization. They can be designed to operate at temperatures up to several hundred degrees Celsius and are often made from high-temperature resistant materials to withstand the harsh environments encountered in these applications.

A CNG (compressed natural gas) mass flow meter is a type of flow meter used to measure the flow rate of compressed natural gas through a pipe or other conduit. Compressed natural gas is a clean-burning alternative fuel that is used in a variety of applications, including transportation, power generation, and industrial processes.

There are several types of CNG mass flow meters, including:

Coriolis Flow Meters: These meters measure the mass flow rate of the CNG by measuring the deflection of a vibrating tube as the gas flows through it.

Thermal Mass Flow Meters: These meters measure the flow rate of the CNG by measuring the amount of heat transferred from a heated element to the gas. The heat transfer rate is proportional to the flow rate of the gas.

CNG mass flow meters are typically used in applications where accurate measurement of CNG flow rates is important, such as in the fueling of CNG vehicles, where precise measurement is critical for billing and inventory control. They can also be used in industrial processes that use CNG as a fuel source, such as in power generation and manufacturing. CNG mass flow meters must be able to withstand the high pressures and temperatures associated with compressed natural gas, which can reach pressures of up to 3,600 psi (250 bar) and temperatures of up to 70°C (158°F).

Digital thermal mass flow meter2020/08/11Digital dispaly, output 4-20mA .

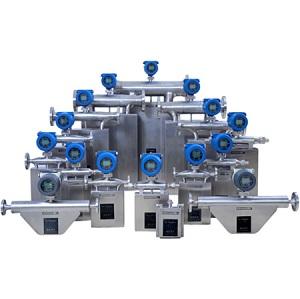

Digital thermal mass flow meter2020/08/11Digital dispaly, output 4-20mA . Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement.

Coriolis Mass Flow Meter2017/04/12Direct mass flow measurement. Vortex steam flow meter2020/02/01Vortex flow meters are not affected by either temperature or pressure and can provide four process measurements (mass flow, volumetric flow, pressure, temperature ) which are useful in the monitoring and control of steam in a process.VIEW

Vortex steam flow meter2020/02/01Vortex flow meters are not affected by either temperature or pressure and can provide four process measurements (mass flow, volumetric flow, pressure, temperature ) which are useful in the monitoring and control of steam in a process.VIEW Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW

Fuel Oil Mass Flow Meter2023/03/02A fuel oil mass flow meter is a type of flow meter that is specifically designed to measure the mass flow rate of fuel oil in a pipeline or process system. Coriolis flow meter is a kind of accurate fuel oil mass flow meter.VIEW Steam Mass Flow Meter2023/04/06Vortex flow meters to measure steam mass flow rate and have digital display to show steam total mass flow . Built-in temperature and pressure compensation .VIEW

Steam Mass Flow Meter2023/04/06Vortex flow meters to measure steam mass flow rate and have digital display to show steam total mass flow . Built-in temperature and pressure compensation .VIEW Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW

Jacketed mass flowmeter2022/11/30What is jacketed mass flowmeter ?Jacketed mass flow meter refer to the Coriolis mass flow meter with thermal jacket, the jacket can be injected steam, hot water, heat transfer oil or other heat preser...VIEW